What is the Main Function of the Thermal Fuse?

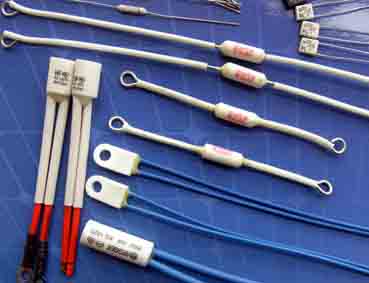

Thermal fuses, also known as temperature fuse, is a kind of non-recoverable overheating safety element. Widely used in various types of electric cookers, electric motors, washing machines, electric fans, power transformers and other electronic products.

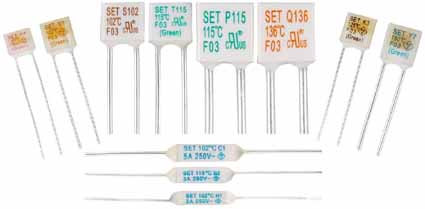

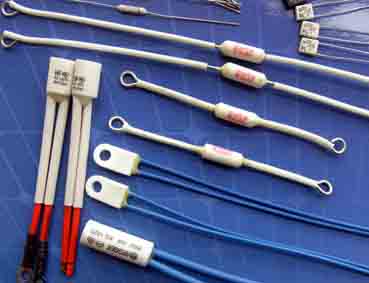

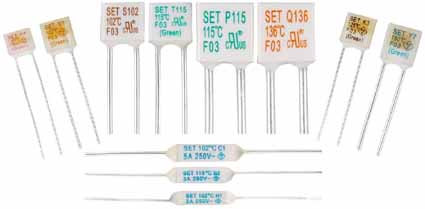

Thermal fuses can be divided into low melting point alloy fuses, It can be divided into low melting point alloy type thermal fuses, organic compound type thermal fuses and plastic-metal type thermal fuses.

1. The temperature sensing body of the low melting point alloy type thermal fuse is processed from an alloy material having a fixed melting point. When the temperature reaches the melting point of the alloy, the temperature sensing body is automatically blown and will be disconnected by the protection circuit.

According to the structure, low-melting alloy type hot low-melting alloy type thermal fuses can be divided into three types: gravity type, surface tension type and spring reaction type.

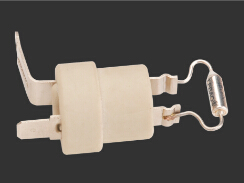

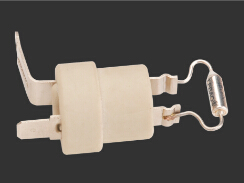

2. The organic compound type thermal fuse is composed of a temperature sensing body, a movable electrode, a spring, etc., as shown in Fig. 17-8.

The temperature sensing body is processed from an organic compound of high purity and low melting temperature range. Normally, the movable electrode is in contact with the fixed end point. The circuit is turned on by the fuse; when the temperature reaches the melting point, the temperature sensing body is automatically blown, and the movable electrode is disconnected from the fixed end point by the action of the spring, and the circuit is disconnected for protection.

3. The plastic-metal type thermal fuse adopts a surface tension type structure, and the temperature sensitive body has a resistance value of almost zero. When the operating temperature reaches the set temperature, the resistance value of the temperature sensing body suddenly increases, preventing the current from passing.

Thermal fuses can be divided into low melting point alloy fuses, It can be divided into low melting point alloy type thermal fuses, organic compound type thermal fuses and plastic-metal type thermal fuses.

1. The temperature sensing body of the low melting point alloy type thermal fuse is processed from an alloy material having a fixed melting point. When the temperature reaches the melting point of the alloy, the temperature sensing body is automatically blown and will be disconnected by the protection circuit.

According to the structure, low-melting alloy type hot low-melting alloy type thermal fuses can be divided into three types: gravity type, surface tension type and spring reaction type.

2. The organic compound type thermal fuse is composed of a temperature sensing body, a movable electrode, a spring, etc., as shown in Fig. 17-8.

The temperature sensing body is processed from an organic compound of high purity and low melting temperature range. Normally, the movable electrode is in contact with the fixed end point. The circuit is turned on by the fuse; when the temperature reaches the melting point, the temperature sensing body is automatically blown, and the movable electrode is disconnected from the fixed end point by the action of the spring, and the circuit is disconnected for protection.

3. The plastic-metal type thermal fuse adopts a surface tension type structure, and the temperature sensitive body has a resistance value of almost zero. When the operating temperature reaches the set temperature, the resistance value of the temperature sensing body suddenly increases, preventing the current from passing.