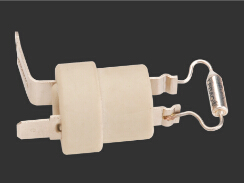

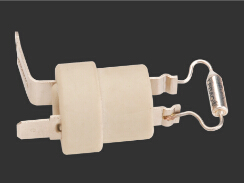

Inline Thermal Fuse

Inline Thermal Fuse uses a low-melting alloy temperature sensor as the main component. When the ambient temperature rises and reaches the melting point of the above-mentioned temperature-sensing body, the temperature-sensing body melts and shrinks into a bead at the end of the lead with the help of the built-in flux, thereby cutting off the current path.

| Specification Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Safety regulations: UL, CUL, CSA, BEAB, TUV, VDE, MITI ① TF—nominal operating temperature ② TOFF-actual cut-off temperature range: the temperature range that changes the conductive state of the hot melt measured under specified conditions. ③ TH-Holding temperature: The maximum temperature of the thermal fuse that will not change its conductive state under the specified conditions and within the specified time. ④ TM-Limit temperature: At this temperature, the electrical conductivity of the thermal fuse has changed, but its mechanical and electrical properties will not change within the specified time. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||