How to Choose the Fuse Parameters?

Is the fuse rated current the operating current?

Does the fuse with rated current 1A break when its current rises to 1A or even slightly higher?

What if I have a pulse surge current occasionally or frequently?

Do you only consider fast-blow or slow-blow characteristics?

Will a larger energy pulse reduce its lifetime?

Will the fuse not break when it should be disconnected? Let's discuss it next.

1. How much current can the fuse flow?

1. How much current can the fuse flow?

Rated current is the current value that the fuse can work for a long time, not the action current.

Because the fuse involves safety issues, it is a safety device and must pass relevant certification before it can be produced and sold.

Generally, safety regulations require that the fuse should not exceed the allowable value when operating at rated current. If the UL specifies 100% of rated current, the temperature should not exceed 75 °C.

Safety regulations also impose stricter requirements on the fuse time when the actual current is greater than the rated current. For example, if a fuse of a certain specification gives 1.5 times rated current, the fuse can last for at least 60 minutes; At 2.1 times the rated current, the maximum operation can last for 2 minutes; It can work for at least 400ms at 2.75 times rated current and can work for up to 10S; There is also a 4 times, 10 times rated current when the fuse time is required.

In addition, the UL specification fuse has a low overload capability and therefore requires a current reduction (Frf = 0.75). For applications such as 3A, at least 4A (3/0.75=4) fuses should be used regardless of other characteristics.

2. How can I work safely?

When the rear stage circuit fails (such as a short circuit), the input voltage is almost all added to the fuse ends! This produces a very large current. Is such a large current causing the fuse to continue to conduct without breaking? It is entirely possible! Therefore, the concept of breaking current is proposed.

IEC and UL have different requirements for breaking capacity. Taking IEC 127 as an example, the following provisions are made:

Low-break (LBC) capability fuses must be able to cut the larger of 35A current or 10 times rated current.

The intermediate breaking (EBC) capability fuse must be able to safely cut off the 150A current;

High Breakage (HBC) fuses must be able to safely cut off 1500A current.

Breaking capacity is the most important safety indicator for fuses. Therefore, when selecting a fuse, this characteristic should be carefully considered, and the actual test, the maximum short-circuit current that may occur in the fuse should not exceed the rated breaking capacity of the fuse. It is guaranteed that when a fault occurs in the latter stage and a large current flows, the fuse can safely cut off the circuit without causing safety problems.

3. How long does the fuse blow? How long does it last?

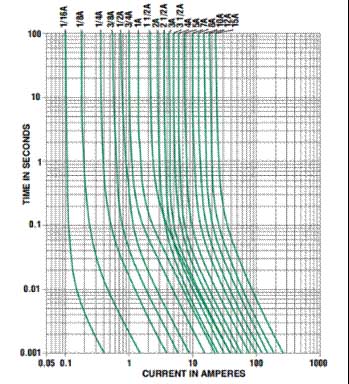

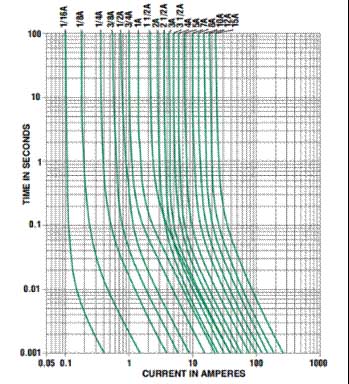

The fuse characteristic, also known as the I-T characteristic. This feature is the main performance indicator. According to the fuse time, the fuse can be divided into fast-melting, slow-melting, and medium-speed fuse. For circuits with resistive circuits or protective sensitive devices, fast-blow fuses should be used; For capacitive and inductive circuits or circuits with large pulses, a slow blow fuse should be used. The figure shows the I-T characteristics of a series of fast-blow fuses. It shows the time range in which the fuse is blown at different current loads.

figure 1 Fuse current time characteristics

Another property to consider regarding fuse blow is the fuse energy I2*t.

Ip2*t is used to indicate the surge energy (nominal fuse energy) that the fuse can withstand, and i2*t is the surge energy in actual operation. When i2*t>Ip2*t, the fuse is blown. By derating the nominal blown energy, you can estimate the number of times the fuse can withstand a surge. There are some differences in the fuses of each brand. For example, some fuses derate to 20% of the nominal blown energy and can withstand 100,000 pulses.

4, the effect of temperature on the fuse

Like semiconductors, fuses are temperature sensitive devices. As the temperature increases, its rated operating current needs to be derated accordingly. It's easy to understand that the fuse itself relies on heat to blow it. Its temperature is equal to the ambient temperature plus the temperature rise during operation. When the ambient temperature is high, it is necessary to reduce its own temperature rise, so the rated current is derated. The temperature reduction rate (Tf) can be used to indicate the corresponding derating factor.

The temperature derating curve is shown in the figure. Taking curve A as an example, the Tf is 0.75 at a temperature of 80 °C. Therefore, if you do not consider the influence of other characteristics, at least 4A (3/0.75=4) fuses should be selected for 3A applications.

Figure 2 fuse ambient temperature characteristics

5, summary

The choice of fuses is often a problem that engineers tend to overlook. More is to simply select the current value, or refer to the specifications of other manufacturers of similar products, often find that the current specifications of the fuse is much different than their own design. This article aims to describe some of the most important basic indicators and provide engineers with some simple selection criteria.

Does the fuse with rated current 1A break when its current rises to 1A or even slightly higher?

What if I have a pulse surge current occasionally or frequently?

Do you only consider fast-blow or slow-blow characteristics?

Will a larger energy pulse reduce its lifetime?

Will the fuse not break when it should be disconnected? Let's discuss it next.

Rated current is the current value that the fuse can work for a long time, not the action current.

Because the fuse involves safety issues, it is a safety device and must pass relevant certification before it can be produced and sold.

Generally, safety regulations require that the fuse should not exceed the allowable value when operating at rated current. If the UL specifies 100% of rated current, the temperature should not exceed 75 °C.

Safety regulations also impose stricter requirements on the fuse time when the actual current is greater than the rated current. For example, if a fuse of a certain specification gives 1.5 times rated current, the fuse can last for at least 60 minutes; At 2.1 times the rated current, the maximum operation can last for 2 minutes; It can work for at least 400ms at 2.75 times rated current and can work for up to 10S; There is also a 4 times, 10 times rated current when the fuse time is required.

In addition, the UL specification fuse has a low overload capability and therefore requires a current reduction (Frf = 0.75). For applications such as 3A, at least 4A (3/0.75=4) fuses should be used regardless of other characteristics.

2. How can I work safely?

When the rear stage circuit fails (such as a short circuit), the input voltage is almost all added to the fuse ends! This produces a very large current. Is such a large current causing the fuse to continue to conduct without breaking? It is entirely possible! Therefore, the concept of breaking current is proposed.

IEC and UL have different requirements for breaking capacity. Taking IEC 127 as an example, the following provisions are made:

Low-break (LBC) capability fuses must be able to cut the larger of 35A current or 10 times rated current.

The intermediate breaking (EBC) capability fuse must be able to safely cut off the 150A current;

High Breakage (HBC) fuses must be able to safely cut off 1500A current.

Breaking capacity is the most important safety indicator for fuses. Therefore, when selecting a fuse, this characteristic should be carefully considered, and the actual test, the maximum short-circuit current that may occur in the fuse should not exceed the rated breaking capacity of the fuse. It is guaranteed that when a fault occurs in the latter stage and a large current flows, the fuse can safely cut off the circuit without causing safety problems.

3. How long does the fuse blow? How long does it last?

The fuse characteristic, also known as the I-T characteristic. This feature is the main performance indicator. According to the fuse time, the fuse can be divided into fast-melting, slow-melting, and medium-speed fuse. For circuits with resistive circuits or protective sensitive devices, fast-blow fuses should be used; For capacitive and inductive circuits or circuits with large pulses, a slow blow fuse should be used. The figure shows the I-T characteristics of a series of fast-blow fuses. It shows the time range in which the fuse is blown at different current loads.

figure 1 Fuse current time characteristics

Another property to consider regarding fuse blow is the fuse energy I2*t.

Ip2*t is used to indicate the surge energy (nominal fuse energy) that the fuse can withstand, and i2*t is the surge energy in actual operation. When i2*t>Ip2*t, the fuse is blown. By derating the nominal blown energy, you can estimate the number of times the fuse can withstand a surge. There are some differences in the fuses of each brand. For example, some fuses derate to 20% of the nominal blown energy and can withstand 100,000 pulses.

4, the effect of temperature on the fuse

Like semiconductors, fuses are temperature sensitive devices. As the temperature increases, its rated operating current needs to be derated accordingly. It's easy to understand that the fuse itself relies on heat to blow it. Its temperature is equal to the ambient temperature plus the temperature rise during operation. When the ambient temperature is high, it is necessary to reduce its own temperature rise, so the rated current is derated. The temperature reduction rate (Tf) can be used to indicate the corresponding derating factor.

The temperature derating curve is shown in the figure. Taking curve A as an example, the Tf is 0.75 at a temperature of 80 °C. Therefore, if you do not consider the influence of other characteristics, at least 4A (3/0.75=4) fuses should be selected for 3A applications.

Figure 2 fuse ambient temperature characteristics

5, summary

The choice of fuses is often a problem that engineers tend to overlook. More is to simply select the current value, or refer to the specifications of other manufacturers of similar products, often find that the current specifications of the fuse is much different than their own design. This article aims to describe some of the most important basic indicators and provide engineers with some simple selection criteria.