Fusible alloy wire (square | ceramic) temperature fuse Commonly used parameters and selection

product name:

Square temperature fuse, ceramic temperature fuse

product description:

Square | ceramic temperature fuse is a fusible alloy wire temperature fuse,Between the two pins connected to a fusible alloy wire,Special resin coated with fusible alloy wire,Current can flow from one pin to the other,When the ambient temperature of the thermal fuse rises to its operating fusing temperature,Its fusible alloy wire melting and under the action of surface tension and special resin to help,Shrunk into a ball attached to the two pin ends.Thus, the circuit is permanently cut off.

Product Features:

Square temperature fuse, ceramic temperature fuse common features:Disposable hot-melt off,Can not be reused.

Square temperature fuse Common current: 1A, 2A, 3A, 5A, 10A, 15A

Ceramic temperature fuse Common current: 1A, 2A, 3A, 5A, 10A, 15A, 20A.

Square temperature fuse commonly used rated operating temperature (Tf):

90C, 102C, 105C, 115C, 125C, 130C, 135C, 138C, 145C, 150C,

Ceramic temperature fuse Common rated operating temperature (Tf):

120C, 125C, 130C, 135C, 138C, 140C, 145C, 150C, 100C,

175 ° C, 180 ° C, 185 ° C, 188 ° C, 190 ° C, 192 ° C, 195 ° C, 200 ° C, 210 ° C, 155 ° C, 160 ° C,

216 ° C, 230 ° C, 240 ° C, 250 ° C

Use the chip:

Fusible alloy wire

Product Size:

Square temperature fuse and ceramic temperature fuse product size by current size classification,High-current temperature fuse,The volume will be larger.

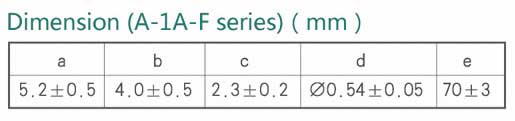

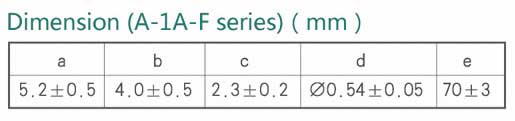

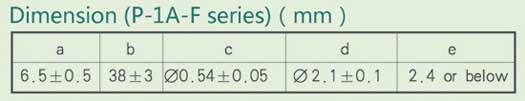

Dimension drawing of 1A square thermal fuse

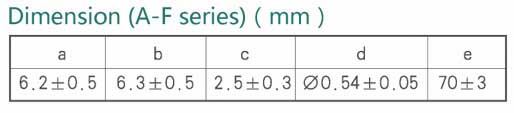

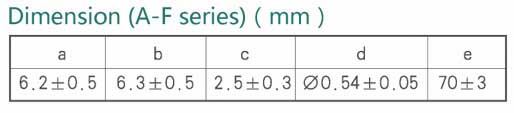

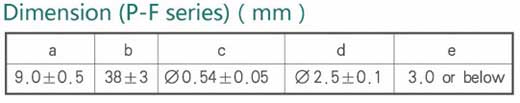

Dimension drawing of 2A square thermal fuse

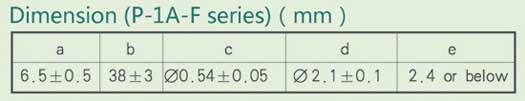

1A ceramic temperature fuse product size drawing

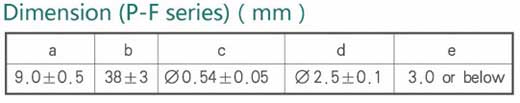

2A ceramic temperature fuse product size drawing

Square | ceramic temperature fuse with different current and temperature,Customers need to be set in accordance with product temperature and current,Select a different product parameters,Yaxun Electronics offers a variety of product design.Welcome to inquire.

Appearance picture:

Square temperature fuse product images Ceramic temperature fuse product images

Applications range:

Temperature Fuse Applications:

Communication field: Mobile terminal

Car: Automotive air conditioning heating seat ABS protection

Home Appliance: Soymilk Maker Hair Dryer Iron / Garment Press Juicer Breadmaker Electric Fan More

Large appliances: air conditioning refrigerator electric washing machine

Optoelectronics: Halogen LED lights start capacitor

Components: Capacitance resistance MOV

Electric cars: battery charging

Industrial Control and Automation: Automatic Robots

Composition Materials:

Ceramic temperature fuse Material:By the axis symmetrical lead (Lead),Fusible alloys,In order to prevent its melting and oxidation of the special mixture (special compound) and insulating ceramic tube (ceramic insulator)

Square-shaped temperature fuse material:By the axis symmetrical lead (Lead), Fusible alloys,To prevent its melting and oxidation of the special mixture (special compound) and a square plastic shell (Plastic insulator)

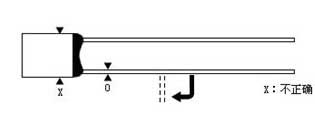

Precautions for use:

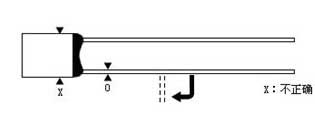

● The temperature fuse pin can not be damaged during installation, it is notched, sharp angle bending, burning.

● The temperature fuse sealing resin and the shell can not be damaged, burned or overheated.

● Do not twist the thermal fuse (for example, the pin rotates relative to the housing).

● Avoid applying an angled force to the pin (eg, push or pull the lead at an angle relative to the housing) This will hurt the sealing resin.

● Do not apply excessive pressure to the housing, sealing resin or pins when fixing the temperature fuse(Such as pulling the temperature fuse, clamping too tight or tied too tight),This can cause damage to the thermal fuse or stress concentration on the leads.

● The connection leads should have sufficient remaining length and be soft enough,The temperature fuse and the hinge point should be fixed,In order to avoid the normal use of the vibration caused by loose hinge.

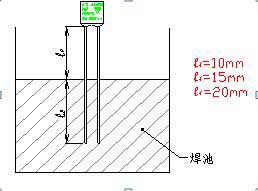

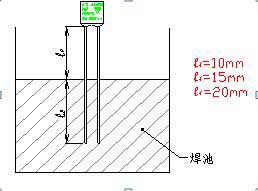

● The distance from the welding point to the root of the thermal fuse is not less than 10mm ((figure 1));

● welding time of not more than 3s;

● When welding by hand to increase the welding fixture,Such as the temperature fuse pin on the clip on the aluminum block or other heat dissipation of the metal,To enhance heat dissipation; ( Figure 1)

• Immerse the fuse pins in the coolant (eg, alcohol) after soldering the temperature fuse.

(figure 1)

Square temperature fuse, ceramic temperature fuse

product description:

Square | ceramic temperature fuse is a fusible alloy wire temperature fuse,Between the two pins connected to a fusible alloy wire,Special resin coated with fusible alloy wire,Current can flow from one pin to the other,When the ambient temperature of the thermal fuse rises to its operating fusing temperature,Its fusible alloy wire melting and under the action of surface tension and special resin to help,Shrunk into a ball attached to the two pin ends.Thus, the circuit is permanently cut off.

Product Features:

Square temperature fuse, ceramic temperature fuse common features:Disposable hot-melt off,Can not be reused.

Square temperature fuse Common current: 1A, 2A, 3A, 5A, 10A, 15A

Ceramic temperature fuse Common current: 1A, 2A, 3A, 5A, 10A, 15A, 20A.

Square temperature fuse commonly used rated operating temperature (Tf):

90C, 102C, 105C, 115C, 125C, 130C, 135C, 138C, 145C, 150C,

Ceramic temperature fuse Common rated operating temperature (Tf):

120C, 125C, 130C, 135C, 138C, 140C, 145C, 150C, 100C,

175 ° C, 180 ° C, 185 ° C, 188 ° C, 190 ° C, 192 ° C, 195 ° C, 200 ° C, 210 ° C, 155 ° C, 160 ° C,

216 ° C, 230 ° C, 240 ° C, 250 ° C

Use the chip:

Fusible alloy wire

Product Size:

Square temperature fuse and ceramic temperature fuse product size by current size classification,High-current temperature fuse,The volume will be larger.

Dimension drawing of 1A square thermal fuse

Dimension drawing of 2A square thermal fuse

1A ceramic temperature fuse product size drawing

2A ceramic temperature fuse product size drawing

Square | ceramic temperature fuse with different current and temperature,Customers need to be set in accordance with product temperature and current,Select a different product parameters,Yaxun Electronics offers a variety of product design.Welcome to inquire.

Appearance picture:

Square temperature fuse product images Ceramic temperature fuse product images

Applications range:

Temperature Fuse Applications:

Communication field: Mobile terminal

Car: Automotive air conditioning heating seat ABS protection

Home Appliance: Soymilk Maker Hair Dryer Iron / Garment Press Juicer Breadmaker Electric Fan More

Large appliances: air conditioning refrigerator electric washing machine

Optoelectronics: Halogen LED lights start capacitor

Components: Capacitance resistance MOV

Electric cars: battery charging

Industrial Control and Automation: Automatic Robots

Composition Materials:

Ceramic temperature fuse Material:By the axis symmetrical lead (Lead),Fusible alloys,In order to prevent its melting and oxidation of the special mixture (special compound) and insulating ceramic tube (ceramic insulator)

Square-shaped temperature fuse material:By the axis symmetrical lead (Lead), Fusible alloys,To prevent its melting and oxidation of the special mixture (special compound) and a square plastic shell (Plastic insulator)

Precautions for use:

● The temperature fuse pin can not be damaged during installation, it is notched, sharp angle bending, burning.

● The temperature fuse sealing resin and the shell can not be damaged, burned or overheated.

● Do not twist the thermal fuse (for example, the pin rotates relative to the housing).

● Avoid applying an angled force to the pin (eg, push or pull the lead at an angle relative to the housing) This will hurt the sealing resin.

● Do not apply excessive pressure to the housing, sealing resin or pins when fixing the temperature fuse(Such as pulling the temperature fuse, clamping too tight or tied too tight),This can cause damage to the thermal fuse or stress concentration on the leads.

● The connection leads should have sufficient remaining length and be soft enough,The temperature fuse and the hinge point should be fixed,In order to avoid the normal use of the vibration caused by loose hinge.

● The distance from the welding point to the root of the thermal fuse is not less than 10mm ((figure 1));

● welding time of not more than 3s;

● When welding by hand to increase the welding fixture,Such as the temperature fuse pin on the clip on the aluminum block or other heat dissipation of the metal,To enhance heat dissipation; ( Figure 1)

• Immerse the fuse pins in the coolant (eg, alcohol) after soldering the temperature fuse.

(figure 1)