What is motor protector?

The role of the motor protector is to provide complete protection of the motor. A device that alarms or protects the motor when there is overload, overcurrent, phase loss, stall, short circuit, overvoltage, undervoltage, leakage, three-phase unbalance, overheating, bearing wear, and eccentricity of the stator.

Selection

There are no uniform standards for motor protection products on the market, and the model specifications are varied.

In order to meet the different needs of users, manufacturers have derived a large number of series of products, which have a variety of inconveniences for the selection of users;

Users should fully consider the actual needs of motor protection when selecting the type, and reasonably choose the protection function and protection method to achieve good protection effect. To achieve the purpose of improving equipment operation reliability, reducing unplanned parking, and reducing accident losses.

(1) Conditions related to selection

1, motor parameters: First understand the motor specifications, functional characteristics, protection type, rated voltage, rated current, rated power, power frequency, insulation level and so on. These contents basically provide a reference for the user to correctly select the protector.

2. Environmental conditions: Mainly refers to normal temperature, high temperature, high cold, corrosion degree, vibration, sand, altitude, electromagnetic pollution.

3, motor use: Mainly refers to the characteristics of the mechanical equipment required to drag, such as fans, pumps, air compressors, lathes, oil field pumping units and other mechanical properties of different loads.

4. Control method: The control modes include manual, automatic, local control, remote control, stand-alone operation, and centralized control of the production line. Start-up methods include direct, step-down, star angle, frequency sensitive varistor, inverter, and soft start.

5. Other aspects: The user's on-site production monitoring management, the severity of the impact of abnormal shutdown on production.

3. Intelligent type:

The three-phase current value is detected, and the protector uses a single-chip microcomputer to realize intelligent comprehensive protection of the motor, integrating protection, measurement, communication, and display. The setting current is digitally set and operated by operating the panel buttons. The user can modify the parameters on the spot according to the specific conditions of the motor; The use of digital tube as a display window, or the use of large-screen liquid crystal display, can support a variety of communication protocols. Such as ModBUS, ProfiBUS, etc., the price is relatively high, for more important occasions; High-voltage motor protection uses intelligent protection devices.

4, thermal protection type:

The thermal element is embedded in the motor and protected according to the temperature of the motor winding, and the protection effect is good; However, when the motor capacity is large, it needs to be used together with the current monitoring type to avoid the motor winding being damaged due to the hysteresis of the temperature measuring component when the temperature of the motor is suddenly increased.

5, magnetic field temperature detection type:

The magnetic field detecting coil and the temperature measuring element are embedded in the motor, and are protected according to changes in the internal rotating magnetic field of the motor and changes in temperature. The main functions include overload, stall, phase loss, overheat protection and wear monitoring, and the protection function is perfect. The disadvantage is the need to install a magnetic field detection coil and a temperature sensor inside the motor.

Selection

There are no uniform standards for motor protection products on the market, and the model specifications are varied.

In order to meet the different needs of users, manufacturers have derived a large number of series of products, which have a variety of inconveniences for the selection of users;

Users should fully consider the actual needs of motor protection when selecting the type, and reasonably choose the protection function and protection method to achieve good protection effect. To achieve the purpose of improving equipment operation reliability, reducing unplanned parking, and reducing accident losses.

(1) Conditions related to selection

1, motor parameters: First understand the motor specifications, functional characteristics, protection type, rated voltage, rated current, rated power, power frequency, insulation level and so on. These contents basically provide a reference for the user to correctly select the protector.

2. Environmental conditions: Mainly refers to normal temperature, high temperature, high cold, corrosion degree, vibration, sand, altitude, electromagnetic pollution.

3, motor use: Mainly refers to the characteristics of the mechanical equipment required to drag, such as fans, pumps, air compressors, lathes, oil field pumping units and other mechanical properties of different loads.

4. Control method: The control modes include manual, automatic, local control, remote control, stand-alone operation, and centralized control of the production line. Start-up methods include direct, step-down, star angle, frequency sensitive varistor, inverter, and soft start.

5. Other aspects: The user's on-site production monitoring management, the severity of the impact of abnormal shutdown on production.

There are many factors related to the selection of protectors, such as installation location, power supply conditions, power distribution system conditions, etc. Also consider whether to protect the newly purchased motor configuration, or to upgrade the motor protection, or to improve the protection of the accident motor; Also consider the difficulty of changing the motor protection method and the degree of impact on production; The selection and adjustment of the protector should be considered comprehensively according to the actual working conditions on site.

(2) Common types of motor protectors

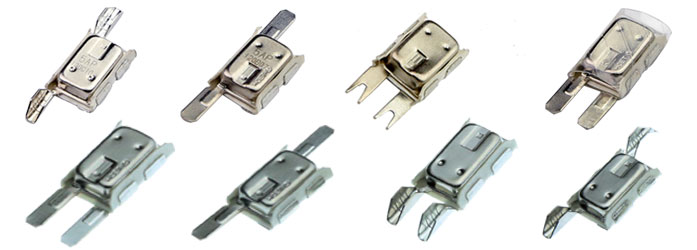

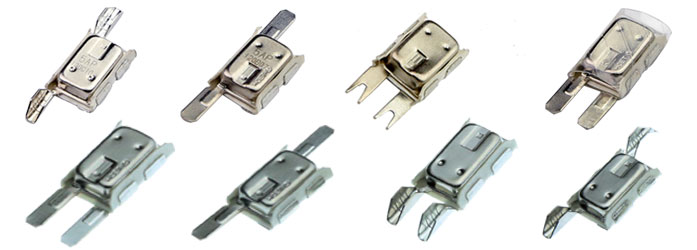

1, thermal relay:

Ordinary small-capacity AC motor, working conditions are good, there is no occasion of severe conditions such as frequent start-up; Due to poor accuracy, reliability is not guaranteed and is not recommended.

2, electronic type:

The three-phase current value is detected, and the potentiometer or the code switch is used for setting the current value. The circuit is generally analog, and adopts an inverse time limit or a time limit operation characteristic. The protection functions include overload, phase loss, stall, etc. The fault type is displayed by an indicator light, and the running power is displayed by a digital tube.

(2) Common types of motor protectors

1, thermal relay:

Ordinary small-capacity AC motor, working conditions are good, there is no occasion of severe conditions such as frequent start-up; Due to poor accuracy, reliability is not guaranteed and is not recommended.

2, electronic type:

The three-phase current value is detected, and the potentiometer or the code switch is used for setting the current value. The circuit is generally analog, and adopts an inverse time limit or a time limit operation characteristic. The protection functions include overload, phase loss, stall, etc. The fault type is displayed by an indicator light, and the running power is displayed by a digital tube.

3. Intelligent type:

The three-phase current value is detected, and the protector uses a single-chip microcomputer to realize intelligent comprehensive protection of the motor, integrating protection, measurement, communication, and display. The setting current is digitally set and operated by operating the panel buttons. The user can modify the parameters on the spot according to the specific conditions of the motor; The use of digital tube as a display window, or the use of large-screen liquid crystal display, can support a variety of communication protocols. Such as ModBUS, ProfiBUS, etc., the price is relatively high, for more important occasions; High-voltage motor protection uses intelligent protection devices.

4, thermal protection type:

The thermal element is embedded in the motor and protected according to the temperature of the motor winding, and the protection effect is good; However, when the motor capacity is large, it needs to be used together with the current monitoring type to avoid the motor winding being damaged due to the hysteresis of the temperature measuring component when the temperature of the motor is suddenly increased.

5, magnetic field temperature detection type:

The magnetic field detecting coil and the temperature measuring element are embedded in the motor, and are protected according to changes in the internal rotating magnetic field of the motor and changes in temperature. The main functions include overload, stall, phase loss, overheat protection and wear monitoring, and the protection function is perfect. The disadvantage is the need to install a magnetic field detection coil and a temperature sensor inside the motor.