Motor overload Breaker protector wiring diagram analysis

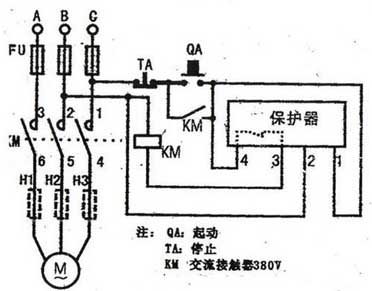

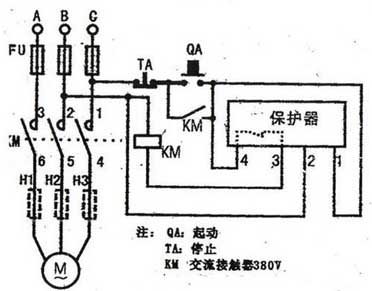

When the motor is overloaded (greater than the preset current of the protector) or the motor is disconnected (one or more phases without current), the normally closed shock 3 or 4 will be temporarily disconnected (the circuit in the figure). Therefore, the contactor will be reset after the loss of power and the original (closed) state will be restored for 3 or 4.

The motor Breaker protector consists of a three-phase current transformer, detection, amplification, delay, adjustment circuit and execution relay. When the detection circuit detects that the current induced by the current transformer is out of phase or is greater than the set value, the amplifier is amplified to activate the relay. The relay contact is connected in series with the contactor coil power supply circuit, and the contactor is powered off after the relay acts to protect the motor. The delay circuit is used to avoid the starting current of the motor and its duration is adjustable. The adjustment circuit is used to accurately set the operating current according to the operating current of the protected motor.

3, 4 are normally open contacts, 1, 2 (coils) are respectively connected to the A and C phases of the power supply (at startup), and the two ends of the KM coil are respectively connected to C and A (via 3, 4) phases; If the protector is activated, 3 and 4 are disconnected, and the KM coil circuit is disconnected and the power is reset.

First, the working principle The main protection of the motor star triangle start mode is the thermal relay. If a large relay is used to protect a large motor, the breakage point of the large wire (that is, the screw connection to and from the thermal relay) may occur, and the heating point and the failure point are likely to occur.

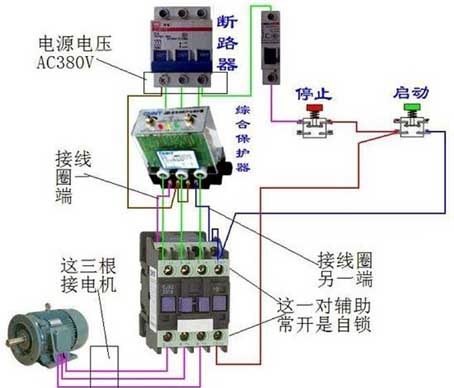

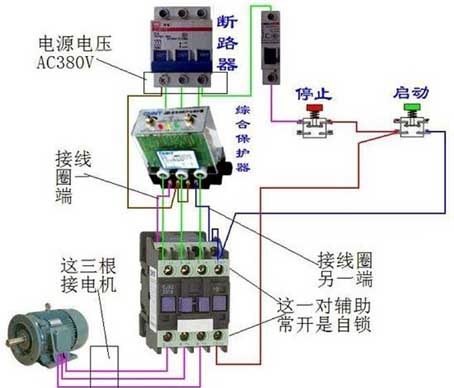

If a fuse and a thermal relay are not used, a motor integrated protector is used. Because the motor integrated protector is a core-through type, it can reduce the breakpoint of large wires, thereby reducing the hot spots and fault points, and the price is cheaper than the two.

When using the motor integrated protector, you must pay attention to the wiring problem of the control circuit. To ensure proper operation.

Some motor integrated protectors indicate: "Be sure to connect the load to work normally. If the load is not connected, it will be in phase loss. Therefore, the integrated protector is refused to be closed and the motor will not start." This shows that the inside of the motor integrated protector relies on the current transformer to detect the presence or absence of three-phase current to determine the phase loss. When the power is not on and there is no load. This closed point is actually an opening point, so there is no way to close it. Such as the model of the JD-6-300A motor integrated protector.

With the action of the button, the problem of the opening and closing point of the protector current detection is staggered. In the front of the line pack of the time relay, the two auxiliary closed points of KM01 and KM02 are connected in parallel to turn off the time relay after the start of the start (because the time relay continues to energize, it does not make sense). The principle of JD-6 motor integrated protector is shown in Figure 2. Anti-time characteristic protection function with phase loss and overload.

The circuit mainly consists of a dual time-base IC chip NE556 and a voltage and current sampling link to form a comparison circuit, a multi-resonant circuit, a monostable circuit and the like.

Briefly read as follows:

1. Phase loss protection L1~L3. Three current transformers are sampled, and an AND gate composed of three transistors U9~U11 obtains a threshold potential on the resistor R4.

In the absence of phase, as long as one of the transistors is turned off and a low potential is formed on R4, the red LED is bright, indicating a phase loss. At the same time, the capacitor C6 is quickly charged, and the left 555 time base of the NE556 constitutes a comparison unit.

The OUT5 output of the NE556 is high, the relay K1 is disconnected, and the external protection point is also disconnected, so that the contactor circuit is tripped and the motor is powered off and protected by phase loss.

When there is no phase loss, when a high potential is formed on R4, the capacitor C6 cannot be charged, and the 5 pin of the OUT1 output terminal of the NE556 becomes a low potential, and K1 is attracted. The external protection point is the closed point, and the motor has the conditions for starting.

2. After the normal running motor starts, during normal operation, the sampling potential of the current transformer will not be higher than the internal comparison potential of the time base. The multi-resonant circuit also becomes a comparison circuit. The 9th pin of the OUT2 output of the NE556 turns into a high potential, and the green LED is always on, indicating that the operation is normal.

3. When the overload protection is overloaded, the sampling potential on R4 is higher than the internal comparison potential of the time base. As the amount of overload increases or time increases, the sampling potential on R4 increases relatively. Therefore, the frequency of the multi-resonant circuit will also increase. Corresponding to the potential of the 9 pin of the OUT2 output of the NE556, the height changes alternately (the only deficiency is:

The current sampling of this motor integrated protector has only one phase. Once the potential of the 9-pin is low, the monostable circuit capacitor C6 starts to charge and is charged according to the changing frequency. When the motor overload current multiplier is large, the low-level time is relatively long corresponding to the multi-resonant sway pulse, and the C6 charging speed is faster; Conversely, when the overload current multiplier is small, the C6 charging speed is slower. This makes the overload protection of the motor have inverse time characteristics. After reaching the set current and time.

The monostable flip, the 5 pin of the OUT1 output of the NE556 becomes high, and the relay K1 is disconnected, that is, the external protection point is also disconnected. The contactor circuit is tripped and the motor can no longer be operated and protected from overload.

2. When the overcurrent setting of a large motor is conditional, it can be set with a low voltage and a large current, as shown in Figure 3.

Figure 1 T1 is a 1kVA single-phase voltage regulator, and 12 is a 500VA, 380W36V working light transformer. The wire is wound 10 turns in the motor integrated protector. Use a clamp-type ammeter to clamp the 36V of the transformer T2. Slowly increase the voltage. Observe the clamp ammeter reading. If the corresponding motor is 110kW, it is about 250A.

In the change from 220A to 250A, the overload yellow indicator light changes from blinking to long light, achieving overcurrent protection. The motor overcurrent multiple is set between 1.25 and 1.5 times the rated current, and the time is set to the inverse time characteristic. That is, the current is shorter than the current, but the entire length of time should be greater than the startup time.

The entire commissioning process takes a short time because the transformer and regulator components are in a safe short-circuit condition. It is a bit of a hassle to use a motor integrated protector. Therefore, some people like to use thermal relay. This familiar form of the device. In the form of Figure 4, it is a structural form of a thermal relay. But "to be small and big". Overcome the shortcomings of large thermal relays that must make the big line "breakpoint". In this way, the current transformer samples the current signal. To characterize the current condition of the motor during startup and operation. The large wires with the motor are non-contact.

The thermal overload protection function is realized by a small thermal relay. It has also been done to reduce the "breakpoint" of the big line and the problem of heat and failure.

This method, like the motor integrated protector, is also non-contact and energy efficient. By the way, can the manufacturer change the large thermal relay into this form? If the manufacturer makes it integrated, then reduce the capacity of the thermal relay to 0.1-1A, which is convenient and energy-saving. Because the hot bimetal in the thermal relay has an inverse time function during the action.

It is exactly the overcurrent heat protection of the motor.

The motor Breaker protector consists of a three-phase current transformer, detection, amplification, delay, adjustment circuit and execution relay. When the detection circuit detects that the current induced by the current transformer is out of phase or is greater than the set value, the amplifier is amplified to activate the relay. The relay contact is connected in series with the contactor coil power supply circuit, and the contactor is powered off after the relay acts to protect the motor. The delay circuit is used to avoid the starting current of the motor and its duration is adjustable. The adjustment circuit is used to accurately set the operating current according to the operating current of the protected motor.

3, 4 are normally open contacts, 1, 2 (coils) are respectively connected to the A and C phases of the power supply (at startup), and the two ends of the KM coil are respectively connected to C and A (via 3, 4) phases; If the protector is activated, 3 and 4 are disconnected, and the KM coil circuit is disconnected and the power is reset.

First, the working principle The main protection of the motor star triangle start mode is the thermal relay. If a large relay is used to protect a large motor, the breakage point of the large wire (that is, the screw connection to and from the thermal relay) may occur, and the heating point and the failure point are likely to occur.

If a fuse and a thermal relay are not used, a motor integrated protector is used. Because the motor integrated protector is a core-through type, it can reduce the breakpoint of large wires, thereby reducing the hot spots and fault points, and the price is cheaper than the two.

When using the motor integrated protector, you must pay attention to the wiring problem of the control circuit. To ensure proper operation.

Some motor integrated protectors indicate: "Be sure to connect the load to work normally. If the load is not connected, it will be in phase loss. Therefore, the integrated protector is refused to be closed and the motor will not start." This shows that the inside of the motor integrated protector relies on the current transformer to detect the presence or absence of three-phase current to determine the phase loss. When the power is not on and there is no load. This closed point is actually an opening point, so there is no way to close it. Such as the model of the JD-6-300A motor integrated protector.

With the action of the button, the problem of the opening and closing point of the protector current detection is staggered. In the front of the line pack of the time relay, the two auxiliary closed points of KM01 and KM02 are connected in parallel to turn off the time relay after the start of the start (because the time relay continues to energize, it does not make sense). The principle of JD-6 motor integrated protector is shown in Figure 2. Anti-time characteristic protection function with phase loss and overload.

The circuit mainly consists of a dual time-base IC chip NE556 and a voltage and current sampling link to form a comparison circuit, a multi-resonant circuit, a monostable circuit and the like.

Briefly read as follows:

1. Phase loss protection L1~L3. Three current transformers are sampled, and an AND gate composed of three transistors U9~U11 obtains a threshold potential on the resistor R4.

In the absence of phase, as long as one of the transistors is turned off and a low potential is formed on R4, the red LED is bright, indicating a phase loss. At the same time, the capacitor C6 is quickly charged, and the left 555 time base of the NE556 constitutes a comparison unit.

The OUT5 output of the NE556 is high, the relay K1 is disconnected, and the external protection point is also disconnected, so that the contactor circuit is tripped and the motor is powered off and protected by phase loss.

When there is no phase loss, when a high potential is formed on R4, the capacitor C6 cannot be charged, and the 5 pin of the OUT1 output terminal of the NE556 becomes a low potential, and K1 is attracted. The external protection point is the closed point, and the motor has the conditions for starting.

2. After the normal running motor starts, during normal operation, the sampling potential of the current transformer will not be higher than the internal comparison potential of the time base. The multi-resonant circuit also becomes a comparison circuit. The 9th pin of the OUT2 output of the NE556 turns into a high potential, and the green LED is always on, indicating that the operation is normal.

3. When the overload protection is overloaded, the sampling potential on R4 is higher than the internal comparison potential of the time base. As the amount of overload increases or time increases, the sampling potential on R4 increases relatively. Therefore, the frequency of the multi-resonant circuit will also increase. Corresponding to the potential of the 9 pin of the OUT2 output of the NE556, the height changes alternately (the only deficiency is:

The current sampling of this motor integrated protector has only one phase. Once the potential of the 9-pin is low, the monostable circuit capacitor C6 starts to charge and is charged according to the changing frequency. When the motor overload current multiplier is large, the low-level time is relatively long corresponding to the multi-resonant sway pulse, and the C6 charging speed is faster; Conversely, when the overload current multiplier is small, the C6 charging speed is slower. This makes the overload protection of the motor have inverse time characteristics. After reaching the set current and time.

The monostable flip, the 5 pin of the OUT1 output of the NE556 becomes high, and the relay K1 is disconnected, that is, the external protection point is also disconnected. The contactor circuit is tripped and the motor can no longer be operated and protected from overload.

Therefore, adjusting the switching time of the star triangle start mode and limiting the starting current can make the motor integrated protector qualitatively use.

When overloaded, the potential of the 9 pin of the OUT2 output of the NE556 is constantly changing. The buzzer B1 and the yellow overload indicator connected to the output start intermittently beeping or flashing, which may indicate that the motor is overloaded.

When overloaded, the potential of the 9 pin of the OUT2 output of the NE556 is constantly changing. The buzzer B1 and the yellow overload indicator connected to the output start intermittently beeping or flashing, which may indicate that the motor is overloaded.

Second, the setting and adjustment of the motor integrated protector must have a tuning process. Take the JD-6-300A motor integrated protector as an example.

1. Position setting according to the instructions

(1) Turn the two potentiometers representing time and current clockwise. That is, the time value and current value are the largest.

(2) Under the premise that the motor and control circuit are normal. Start the motor and wait until it is working properly. The green indicator light is on. At this time, slowly reduce the right current potentiometer counterclockwise until the overload yellow warning light flashes. Then, add a little clockwise to the point where the yellow overcurrent indicator does not flash once in 1 minute.

(3) Gradually reduce the left time potentiometer counterclockwise. Greater than the actual start-up time of the motor.

1. Position setting according to the instructions

(1) Turn the two potentiometers representing time and current clockwise. That is, the time value and current value are the largest.

(2) Under the premise that the motor and control circuit are normal. Start the motor and wait until it is working properly. The green indicator light is on. At this time, slowly reduce the right current potentiometer counterclockwise until the overload yellow warning light flashes. Then, add a little clockwise to the point where the yellow overcurrent indicator does not flash once in 1 minute.

(3) Gradually reduce the left time potentiometer counterclockwise. Greater than the actual start-up time of the motor.

2. When the overcurrent setting of a large motor is conditional, it can be set with a low voltage and a large current, as shown in Figure 3.

Figure 1 T1 is a 1kVA single-phase voltage regulator, and 12 is a 500VA, 380W36V working light transformer. The wire is wound 10 turns in the motor integrated protector. Use a clamp-type ammeter to clamp the 36V of the transformer T2. Slowly increase the voltage. Observe the clamp ammeter reading. If the corresponding motor is 110kW, it is about 250A.

In the change from 220A to 250A, the overload yellow indicator light changes from blinking to long light, achieving overcurrent protection. The motor overcurrent multiple is set between 1.25 and 1.5 times the rated current, and the time is set to the inverse time characteristic. That is, the current is shorter than the current, but the entire length of time should be greater than the startup time.

The entire commissioning process takes a short time because the transformer and regulator components are in a safe short-circuit condition. It is a bit of a hassle to use a motor integrated protector. Therefore, some people like to use thermal relay. This familiar form of the device. In the form of Figure 4, it is a structural form of a thermal relay. But "to be small and big". Overcome the shortcomings of large thermal relays that must make the big line "breakpoint". In this way, the current transformer samples the current signal. To characterize the current condition of the motor during startup and operation. The large wires with the motor are non-contact.

The thermal overload protection function is realized by a small thermal relay. It has also been done to reduce the "breakpoint" of the big line and the problem of heat and failure.

This method, like the motor integrated protector, is also non-contact and energy efficient. By the way, can the manufacturer change the large thermal relay into this form? If the manufacturer makes it integrated, then reduce the capacity of the thermal relay to 0.1-1A, which is convenient and energy-saving. Because the hot bimetal in the thermal relay has an inverse time function during the action.

It is exactly the overcurrent heat protection of the motor.