China Manufacturer of Thermal Circuit Breakers

The use of this term may vary in different regions to refer to Thermal circuit breakers actuated by overloads of a circuit or to Thermal circuit breakers actuated by losses of power outside the circuit.

A Thermal circuit breaker (Argentina), automatic switch (Spain), automatic (Chile), differential or taco1 (Colombia), (Nicaragua), Thermal breaker or pastilla (Mexico, Venezuela, Ecuador, Costa Rica and Panama), or flipin (Guatemala) It is a device capable of interrupting or opening an electrical circuit when insulation failures occur in an electrical equipment or installation.

It should not be confused with a thermomagnetic switch because, unlike this one, the Thermal circuit breaker opens the circuit when there is a difference between the incoming and outgoing currents of the circuit. Its main objective is the safety of people, preventing them from being affected by electrical currents when they come into contact with the faulty equipment.

Unlike fuses, which must be replaced after a single use, the Thermal circuit breaker can be reset once the problem that caused its trip has been located and repaired.

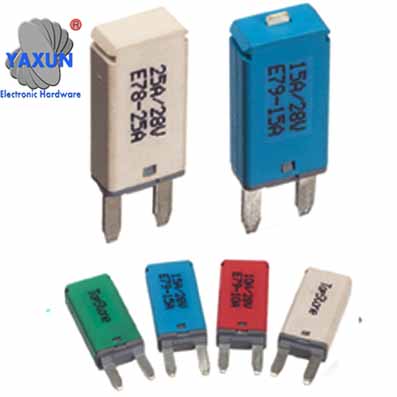

Thermal Circuit breakers are manufactured in different sizes and characteristics, making them widely used in homes, industries, and businesses.

Thermal Circuit breakers Description

The differential Thermal circuit breaker is a protection element for people. It has a differential transformer (that is, it detects differences in current intensity), it has a magnetic core on which the phase is wound (for example, in a clockwise direction) and the neutral (in the opposite direction to the previous one), in addition to a detection coil, which feeds a small electromagnet, which triggers the trigger. When the same amount of current circulates through the phase as through the neutral (normal operation) the magnetic flux is zero, so that in the detection coil the induced voltage is 0 V; as soon as there is a ground leakage (it can be through the third wire or through a person) the total current flows through the phase, but only the total “goes” through the neutral, minus the amount that is being diverted to ground ( this amount depends on each case), so if the difference is greater than the trip, the voltage at the ends of the detector winding is sufficient to activate the electromagnet that performs the disconnection.

Difference with a thermal wrench

The thermal one only protects the installation; inside it has a bimetallic pair (two metals with different expansion coefficients) riveted at one of its ends; When a current greater than the calibrated one circulates (circulates through the pair), one metal expands more than the other, bending the bimetallic pair, which activates the tripping mechanism.

It is always advisable to place a thermal "upstream" of the differential Thermal circuit breaker, and that this is of a smaller caliber, since the Thermal circuit breaker is a more expensive element than the thermal one. In addition to this, it is advisable to have one in any electrical installation and press the test button once a month to verify its correct operation.

Thermal Circuit breakers features

The most important parameters that define a Thermal circuit breaker are:Rating or rated current: working current for which the device is designed. There are from 5 to 64 amps.

Working voltage: voltage for which the Thermal circuit breaker is designed. There are single-phase (110-220 V) and three-phase (300-600 V).

Breaking capacity: maximum current that the Thermal circuit breaker can interrupt. With higher intensities, electric arc phenomena or the fusion and welding of materials can occur that would prevent the opening of the circuit.

Closing power: maximum current that can flow through the device at the time of closing without it being damaged by electric shock.

Number of poles: maximum number of conductors that can be connected to the Thermal circuit breaker. There are one, two, three and four poles.

Thermal Circuit breakers Types

The most commonly used Thermal circuit breakers are those that work with alternating currents, although they also exist for direct currents. The most common types of Thermal circuit breakers are:The word relay is also used relatively frequently, although not completely correctly, to refer to these devices, especially thermal devices.

Colloquially, the name "automatic", "fuses", "plugs" or even "leads" is given to the magnetothermic Thermal circuit breakers and the differential installed in homes.

In the case of railways, a Thermal circuit breaker is used to open and disconnect the main voltage line, cutting the current directly from the pantograph to the rest of the train.

Thermal Circuit breakers Functioning

Thermal devicePresent in thermal and magnetothermic Thermal circuit breakers. It is composed of a calibrated bimetal through which the current that feeds the load circulates. When this is higher than the intensity for which the device is built, it heats up, expands and causes the bimetal to arc, thereby making the switch open automatically. Detects overload faults.

It is made up of a solenoid or electromagnet, whose attractive force increases with the intensity of the current. The switch contacts are kept in electrical contact by means of a latch, and when the current exceeds the range allowed by the appliance, the solenoid releases the latch, separating the contacts by means of a spring. Some types of switches include a hydraulic delay system, immersing the solenoid core in a tube filled with a viscous liquid. The core is supported by a spring that keeps it offset relative to the solenoid as long as the circulating current remains below the switch rating. During an overload, the solenoid draws the core through the fluid to close the magnetic circuit, applying enough force to release the latch. This delay allows short current surges beyond the nominal value of the device, without actually opening the circuit, in situations such as motor starting. The short circuit currents supply sufficient force to the solenoid to release the latch regardless of the position of the core, thereby preventing delayed opening.

Inside a Thermal circuit breaker

Present in magnetic and thermomagnetic Thermal circuit breakers, it is made up of a coil, a core and a moving part. The intensity that feeds the load passes through said coil, and in the event that it is much higher than the nominal intensity of the device, a magnetic field is created that is capable of dragging the moving part and causing the circuit to open almost snapshot. Detects short-circuit faults that may exist in the electrical circuit.Under short-circuit conditions, a current much greater than the nominal current flows;

When an electrical contact opens a circuit where there is a large flow of current, an electrical arc generally occurs between these already open contacts, which allows the current to continue to flow. To avoid this, the switches incorporate characteristics to divide and extinguish the electric arc. In small switches, an arc extinguishing chamber is implemented, which consists of several metal plates or crests of ceramic material, which help to lower the temperature of the arc. The arc is moved into this chamber by the influence of a magnetic blowing coil. In larger Thermal circuit breakers, such as those used in electrical substations, vacuum, inert gases such as sulfur hexafluoride or oil are used to weaken the arc.

The breaking capacity or breaking capacity of a switch is the maximum short-circuit current that it is capable of successfully interrupting without suffering major damage. If the short-circuit current is set higher than the breaking capacity of a switch, it will not be able to interrupt it, and it will be destroyed.

The small switches can be installed directly next to the equipment to be protected, although they are generally arranged on a panel designed for this purpose. Power switches are located in electrical cabinets or cabinets, while high voltage switches can be located outdoors.

PREV:How the Thermal Circuit Breakers Works

NEXT:NONE

NEXT:NONE