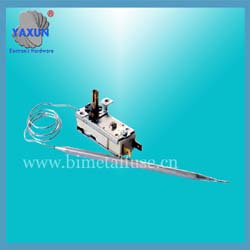

Dual probe bellows plug in thermostat

- PRODUCT DETAIL

First, the dual-control liquid expansion principle performance bipolar Thermostat

Performance principle: to make the thermostat temperature working fluid within the Ministry to produce the corresponding thermal expansion and contraction of the physical phenomena (working fluid volume change) when the object to be controlled temperature changes, together with the temperature sensing portion of the communication bellows produce expansion or contraction. Through leverage, driven by the switch-off operation, to achieve the purpose of constant temperature. WG series of liquid expansion type thermostat with temperature control accurate, reliable, small-OFF temperature, temperature adjustment range

Second, dual-control liquid expansion thermostat uses Bipolar

Mainly used for electric equipment (stainless steel automatic water boilers, embedded oven, electric frying pans, food machinery, medical equipment), refrigeration industry (kitchen freezer, fresh cabinet, refrigerator, ice machine, fish pond, cold drink machine, Heating temperature machine) appliance control.

Third, to bipolar dual control liquid expansion thermostat technical parameters:

1, electrical performance: 16 (3) A-250V ~ 10 (1.8) A-400V ~

2, off temperature: According to user requirements, design temperature range (-35 ℃ ~ + 450 ℃)

3, the product life:> 10 million times

4, the electrical strength: AC2000V / 1min

5, normal insulation resistance: ≥100MΩ

6, the contact resistance: ≤50mΩ

7, tidal insulation resistance: ≥10MΩ

8, the temperature response rate: ≤1.0 ℃ / min

9, the minimum current: 200mA

10. With CE and CQC certification

,, Four double control bipolar liquid expansion thermostat Note:

1, the user must be based on characteristics of their products, the required temperature control, proposed order models and specifications.

2, when the thermostat installed, temperature control is possible, snapping entire surface temperature, in order to achieve accurate temperature control purposes.

3, the installation will not be pressure tube deformation temperature, so as not to affect its performance.

4. Do not allow conductive gas or conductive material into the thermostat or contaminated surface temperature to avoid affecting the electrical insulation properties.

5, M4 wire mounting bracket not too long, otherwise it will damage the thermostat performance.

6, the electrical switch box ceramic pieces gently to avoid damage.

7, the capillary bend radius can not be less than 5mm.

Performance principle: to make the thermostat temperature working fluid within the Ministry to produce the corresponding thermal expansion and contraction of the physical phenomena (working fluid volume change) when the object to be controlled temperature changes, together with the temperature sensing portion of the communication bellows produce expansion or contraction. Through leverage, driven by the switch-off operation, to achieve the purpose of constant temperature. WG series of liquid expansion type thermostat with temperature control accurate, reliable, small-OFF temperature, temperature adjustment range

Second, dual-control liquid expansion thermostat uses Bipolar

Mainly used for electric equipment (stainless steel automatic water boilers, embedded oven, electric frying pans, food machinery, medical equipment), refrigeration industry (kitchen freezer, fresh cabinet, refrigerator, ice machine, fish pond, cold drink machine, Heating temperature machine) appliance control.

Third, to bipolar dual control liquid expansion thermostat technical parameters:

1, electrical performance: 16 (3) A-250V ~ 10 (1.8) A-400V ~

2, off temperature: According to user requirements, design temperature range (-35 ℃ ~ + 450 ℃)

3, the product life:> 10 million times

4, the electrical strength: AC2000V / 1min

5, normal insulation resistance: ≥100MΩ

6, the contact resistance: ≤50mΩ

7, tidal insulation resistance: ≥10MΩ

8, the temperature response rate: ≤1.0 ℃ / min

9, the minimum current: 200mA

10. With CE and CQC certification

,, Four double control bipolar liquid expansion thermostat Note:

1, the user must be based on characteristics of their products, the required temperature control, proposed order models and specifications.

2, when the thermostat installed, temperature control is possible, snapping entire surface temperature, in order to achieve accurate temperature control purposes.

3, the installation will not be pressure tube deformation temperature, so as not to affect its performance.

4. Do not allow conductive gas or conductive material into the thermostat or contaminated surface temperature to avoid affecting the electrical insulation properties.

5, M4 wire mounting bracket not too long, otherwise it will damage the thermostat performance.

6, the electrical switch box ceramic pieces gently to avoid damage.

7, the capillary bend radius can not be less than 5mm.

|

|

|

|

|

|

|

|

|

|