Classification and Function Analysis of Thermistor

(A) polymer PTC thermistor - current protection devices:

Polymer positive temperature coefficient thermistor (PPTC) is the use of special polymer mixed conductive particles to form conductive polymer, Will be connected in series in the circuit, At normal ambient temperatures, Its resistance is very small, Loss is also very small, Does not affect the circuit work;Conductive particles within the material containing the formation of low-resistance molecular structure, Current can be normal through. When the line short-circuit or overload, When the temperature rises to the thermistor (PPTC) protection temperature, The structure of the polymer from the crystalline state into a non-crystalline state, And with the increase in volume, Conductive particles separated, The heat generated by the large current flowing through the self-recovering fuse melts the polymeric resin, The rapid growth of volume, To form a high-resistance state (b), The working current will be rapidly reduced, Thereby limiting and protecting the circuit.

Polymer positive temperature coefficient thermistor has self-recovery function, When troubleshooting, The thermistor re-cooling crystallization, Volume contraction, Conductive particles to form a conductive path, The self-recovery fuse returns to a low-impedance state, Thus completing the protection of the circuit, No manual replacement.

(B) MF11 | MF12 temperature compensation components:

Due to negative temperature coefficient thermistor (NTC) resistance value can be decreased with increasing temperature; The negative temperature coefficient thermistor into the circuit, No negative temperature coefficient thermistor before the circuit with the total resistance increases with temperature (Rc); And with negative temperature coefficient thermistor to do compensation, Total resistance R Total of the circuit does not change significantly with temperature. (Such as to be a sensor. if a single temperature coefficient of the components, The relative error will be relatively large. if the positive and negative temperature coefficient of the combination of components, Just positive and negative phase balance, The error will be relatively small).

(C) of the automotive water temperature sensor - a typical thermistor temperature sensing element

Water temperature sensor using the principle of thermistor, The lower the temperature the higher the resistance; The higher the temperature, the lower the resistance. The resistance of the application thermistor is between 275 ohms and 6500 ohms.

1, the first, The role of automotive water temperature sensor is relatively simple. Is through the thermistor internal resistance changes, Through the current people will change, Thereby driving the water temperature table changes, Indirect tell people the engine operating temperature.

(2), the second, Water temperature sensor from the structure is not much change, But its role is to provide a temperature control of the engine control unit of the analog signal. Its supply voltage is provided by the control unit 5V power supply, The signal returned to the control unit is a linearly varying signal of 1. 3V to 3. 8V. The main role is to tell the engine control unit is now the number of temperature. In turn, its signal for the control unit and its important. Mainly the engine at different working temperatures have different methods of work.

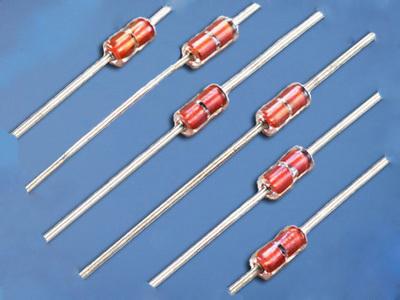

(D) NTC temperature sensor

Negative temperature coefficient thermistor is manganese, cobalt, nickel and copper and other metal oxides as the main material, Using ceramic technology made of. These metal oxide materials are of semiconducting nature, Because in the conduction mode is completely similar to germanium, silicon and other semiconductor materials. When the temperature is low, These oxide materials have a small number of carriers (electrons and holes)So its resistance value is higher;With the increase of temperature, The number of carriers is increased, The resistance value is lowered. NTC thermistor in the use of a certain measurement power, The resistance decreases rapidly with increasing temperature. With this feature, NTC thermistor by measuring its resistance to determine the corresponding temperature, So as to achieve the purpose of detection and control of temperature.

NTC temperature sensor has the advantage of small size, It can quickly stabilize, Will not cause heat load. But also so very strong, Can not pass a large current, If the current is too large to cause self-heating. Since the thermistor is a resistive device, Any current source will generate heat due to power. The power is equal to the square of the current and the product of the resistances. So use a small current source. If the NTC temperature sensor is exposed to high heat and high current, Will cause permanent damage.

(E) power type thermistor

In order to avoid the electronic circuit in the boot of the moment the surge current, In the power supply circuit in series with a power NTC thermistor. Can effectively curb the surge current when the boot, And after the suppression of the inrush current effect is completed, As a result of the ongoing action of its current, Power NTC thermistor resistance in the normal operating temperature and current, Will drop to a very small extent, It consumes power can be ignored, Will not affect the normal operating current. Therefore, the use of power in the power loop NTC thermistor, Is to suppress the boot when the surge, To ensure that electronic equipment from the destruction of the most simple and effective measures.

According to the national standard, Rated zero-power resistance value is NTC thermistor at the reference temperature measured at 25 ℃ resistance R25. This resistor value is the nominal resistance of the NTC thermistor. NTC thermistor is usually said how much resistance, Also refers to the value.

RT refers to the specified temperature T (25 ℃), The resistance value is measured using a measurement power that causes a change in the resistance value relative to the total measurement error to be negligible.