Application circuit of bimetal temperature switch in electric iron & electric rice cooker

The application circuit of the bimetal temperature switch in the electric iron and the rice cooker is taken as an example to introduce the working principle of the bimetal temperature switch.

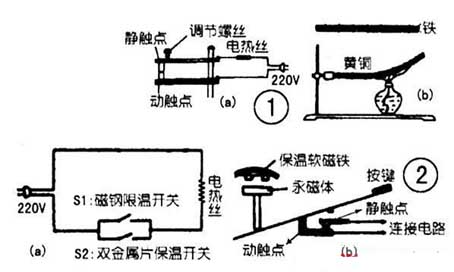

Ironing with an iron, if the temperature is too high, it will burn the clothes, and for different materials, the temperature required for ironing is different, so a temperature adjustment device is needed. Figure 1 is a schematic diagram of the principle of temperature adjustment of an electric iron. The main components of the temperature regulating circuit of the electric iron are bimetal sheets. When the electric iron is working, the dynamic and static contacts are contacted, and the electric and thermal components are electrified and heated.

When the temperature reaches the selected temperature, the bimetal is bent down to make the moving contact leave the static contact, and the power is automatically cut off; when the temperature is lower than the selected temperature, the bimetal recovers and the two contacts close. After the circuit is turned on, the temperature rises again after the power is turned on, and then turns off again when the selected temperature is reached, so that the temperature of the iron can be kept within a certain range. By adjusting the selected temperature of the screw, the lower the screw is, the lower the static contact is, the higher the selected temperature is.

Why do bimetals bend when heated?

This is because it is two different pieces of metal that are tightly spliced together, and if it is at room temperature, it is straight. Then, when it is heated by the temperature rise, the bimetal is gradually bent toward the side with less thermal expansion due to the difference in the degree of thermal expansion of the two metals, as shown in Fig. 1(b). As the temperature decreases, it gradually returns to its original state.

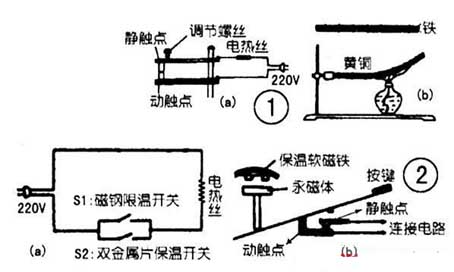

Electric rice cooker is a commonly used cooker, it can cook rice, but also heat preservation, the whole process of automation, easy to use. The temperature control circuit diagram of the rice cooker is shown in Fig. 2.

Inside the rice cooker, there is a magnetic steel temperature limit switch S1 and a bimetal heat preservation switch S2. When the cooking starts, press the switch S1, the circuit is turned on, and the heating wire is energized to cook. When there is water in the pot, the temperature of the rice cooker will not exceed 100 ° C; after the rice is cooked, the water will dry and the temperature of the rice cooker will exceed 100 ° C. When the temperature rises to 103 °C, the temperature limit switch S1 will be automatically disconnected, and the circuit will be powered off to achieve the purpose of automatic temperature control. At this time, the temperature is high and S2 is in the off state. When the temperature drops to 60 ° C, S2 is turned on; when heated to 80 ° C, S2 is turned off again. The unsinking of S2 keeps the temperature inside the pot between 60-80 °C.

Why is the magnetic steel temperature limit switch automatically disconnected at 103 °C?

It can be understood by referring to the working diagram of the magnetic steel temperature limiting component shown in Fig. 2(b). When the button is pressed, the movable contact contacts the stationary contact and is energized. At the same time, the permanent magnet contacts with the temperature-sensitive soft magnet, and the soft magnet is magnetized to absorb the permanent magnet. At this time, the hand does not need to press the button, and the circuit is still connected. The temperature-sensitive soft magnet has a unique property. When the temperature reaches 103 ° C, the magnetic properties disappear and the permanent magnet cannot be attracted. Therefore, when the bottom temperature reaches 103 ° C, the permanent magnet falls due to gravity, and the moving contact leaves the static contact to disconnect the power supply, thereby achieving protection.

Ironing with an iron, if the temperature is too high, it will burn the clothes, and for different materials, the temperature required for ironing is different, so a temperature adjustment device is needed. Figure 1 is a schematic diagram of the principle of temperature adjustment of an electric iron. The main components of the temperature regulating circuit of the electric iron are bimetal sheets. When the electric iron is working, the dynamic and static contacts are contacted, and the electric and thermal components are electrified and heated.

When the temperature reaches the selected temperature, the bimetal is bent down to make the moving contact leave the static contact, and the power is automatically cut off; when the temperature is lower than the selected temperature, the bimetal recovers and the two contacts close. After the circuit is turned on, the temperature rises again after the power is turned on, and then turns off again when the selected temperature is reached, so that the temperature of the iron can be kept within a certain range. By adjusting the selected temperature of the screw, the lower the screw is, the lower the static contact is, the higher the selected temperature is.

Why do bimetals bend when heated?

This is because it is two different pieces of metal that are tightly spliced together, and if it is at room temperature, it is straight. Then, when it is heated by the temperature rise, the bimetal is gradually bent toward the side with less thermal expansion due to the difference in the degree of thermal expansion of the two metals, as shown in Fig. 1(b). As the temperature decreases, it gradually returns to its original state.

Electric rice cooker is a commonly used cooker, it can cook rice, but also heat preservation, the whole process of automation, easy to use. The temperature control circuit diagram of the rice cooker is shown in Fig. 2.

Inside the rice cooker, there is a magnetic steel temperature limit switch S1 and a bimetal heat preservation switch S2. When the cooking starts, press the switch S1, the circuit is turned on, and the heating wire is energized to cook. When there is water in the pot, the temperature of the rice cooker will not exceed 100 ° C; after the rice is cooked, the water will dry and the temperature of the rice cooker will exceed 100 ° C. When the temperature rises to 103 °C, the temperature limit switch S1 will be automatically disconnected, and the circuit will be powered off to achieve the purpose of automatic temperature control. At this time, the temperature is high and S2 is in the off state. When the temperature drops to 60 ° C, S2 is turned on; when heated to 80 ° C, S2 is turned off again. The unsinking of S2 keeps the temperature inside the pot between 60-80 °C.

Why is the magnetic steel temperature limit switch automatically disconnected at 103 °C?

It can be understood by referring to the working diagram of the magnetic steel temperature limiting component shown in Fig. 2(b). When the button is pressed, the movable contact contacts the stationary contact and is energized. At the same time, the permanent magnet contacts with the temperature-sensitive soft magnet, and the soft magnet is magnetized to absorb the permanent magnet. At this time, the hand does not need to press the button, and the circuit is still connected. The temperature-sensitive soft magnet has a unique property. When the temperature reaches 103 ° C, the magnetic properties disappear and the permanent magnet cannot be attracted. Therefore, when the bottom temperature reaches 103 ° C, the permanent magnet falls due to gravity, and the moving contact leaves the static contact to disconnect the power supply, thereby achieving protection.