Thermal protector components for motors

Thermal protector elements of motors are critical components in operating automation equipment. This provides a degree of protection against excessive winding temperatures, which can eventually lead to permanent winding insulation breakdown and failure.

Let’s look at a hypothetical example – a manufacturing company is using servo motors on a new assembly machine. The machine started out running fine, but then the company decided they needed faster output, so the duty cycle of the motor was increased. Over time, higher cycles will result in higher rms motor current. This higher rms current accumulates a large amount of energy in the form of heat inside the motor windings.

Let’s look at a hypothetical example – a manufacturing company is using servo motors on a new assembly machine. The machine started out running fine, but then the company decided they needed faster output, so the duty cycle of the motor was increased. Over time, higher cycles will result in higher rms motor current. This higher rms current accumulates a large amount of energy in the form of heat inside the motor windings.

The motor eventually began to overheat, the motor windings failed, and the production line was shut down. The motor needs to be sent to the original factory for rewinding or complete replacement. After investigation, the manufacturing company did not install a thermal protector inside the coil for overheating protection. This failure was entirely avoidable.

Thermal protector (temperature protector) embedded in motor windings

Thermal protector (temperature protector) embedded in motor windings

What is overheating protection?

There are many different options for overheating protection, but the basic principles are the same. Winding protection uses a thermal protector to monitor the thermal condition of the motor's stator winding. When thermal overload occurs, thermal winding protection will cause the motor to shut down.

Embedded motor thermal protection

Embedded motor thermal protection

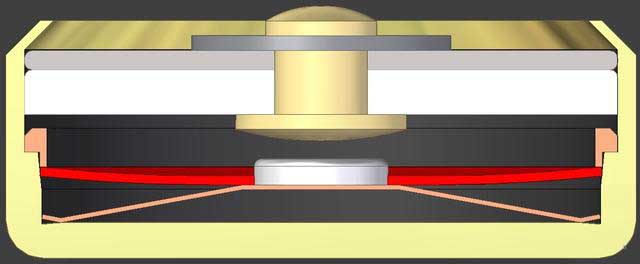

Depending on the thermal protection device used, the method of thermal measurement and the interaction of the protection device with the KEB Variable Frequency Drive (VFD) may differ. Here we discuss the motor thermal protector together. For example, Saftty's miniature thermal protectors: ST01ST06, are all button-type thermal protectors. It is small in size and can be wound inside a coil, and is resistant to vacuuming and paint dipping.

Button type thermal protector

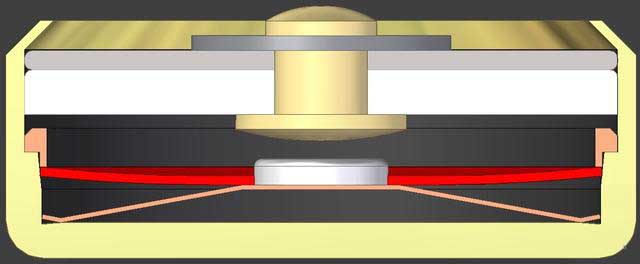

The bimetallic strip is the operating component of the thermal motor overload relay. Thermal protectors are one of the most common and economical motor overload protection devices, especially for single-phase motors. As mentioned earlier, a thermal protector consists of a bimetallic strip, a mechanical device that converts temperature changes into mechanical displacement. A bimetal consists of two different metal sheets with different coefficients of thermal expansion. The two strips are held together by riveting or welding along their length. When heated, different thermal expansion characteristics cause the two metals to expand at different rates. If heated above its ambient temperature, this will cause the bimetal to bend/deflect in one direction.

Bimetal thermal protector disconnected state

The thermal protector is installed in the motor circuit and the current flowing to the motor passes through a bimetallic trip element. The flowing current heats the bimetal, causing it to bend, and after a certain temperature, the bimetal opens the relay. When the relay is opened, the current flow to the motor is removed and the motor and motor circuit are closed. Thermal protectors have a classification called a trip level, which represents the response time to overload conditions. Typically, the trip level is Level 10, Level 20 or Level 30.

The thermal protector is installed in the motor circuit and the current flowing to the motor passes through a bimetallic trip element. The flowing current heats the bimetal, causing it to bend, and after a certain temperature, the bimetal opens the relay. When the relay is opened, the current flow to the motor is removed and the motor and motor circuit are closed. Thermal protectors have a classification called a trip level, which represents the response time to overload conditions. Typically, the trip level is Level 10, Level 20 or Level 30.

Bimetal thermal protector closed state

Thermal protectors with bimetal strips are relatively cost-effective and do not require advanced controls to read the information. They are basically binaries with on/off states. The downside is that there's little that can be done about the rise in temperature until it's completely shut down. The thermal protector will only operate when the peak temperature is reached.

The motor eventually began to overheat, the motor windings failed, and the production line was shut down. The motor needs to be sent to the original factory for rewinding or complete replacement. After investigation, the manufacturing company did not install a thermal protector inside the coil for overheating protection. This failure was entirely avoidable.

What is overheating protection?

There are many different options for overheating protection, but the basic principles are the same. Winding protection uses a thermal protector to monitor the thermal condition of the motor's stator winding. When thermal overload occurs, thermal winding protection will cause the motor to shut down.

Depending on the thermal protection device used, the method of thermal measurement and the interaction of the protection device with the KEB Variable Frequency Drive (VFD) may differ. Here we discuss the motor thermal protector together. For example, Saftty's miniature thermal protectors: ST01ST06, are all button-type thermal protectors. It is small in size and can be wound inside a coil, and is resistant to vacuuming and paint dipping.

Button type thermal protector

The bimetallic strip is the operating component of the thermal motor overload relay. Thermal protectors are one of the most common and economical motor overload protection devices, especially for single-phase motors. As mentioned earlier, a thermal protector consists of a bimetallic strip, a mechanical device that converts temperature changes into mechanical displacement. A bimetal consists of two different metal sheets with different coefficients of thermal expansion. The two strips are held together by riveting or welding along their length. When heated, different thermal expansion characteristics cause the two metals to expand at different rates. If heated above its ambient temperature, this will cause the bimetal to bend/deflect in one direction.

Bimetal thermal protector disconnected state

Bimetal thermal protector closed state

Thermal protectors with bimetal strips are relatively cost-effective and do not require advanced controls to read the information. They are basically binaries with on/off states. The downside is that there's little that can be done about the rise in temperature until it's completely shut down. The thermal protector will only operate when the peak temperature is reached.

PREV:Thermal Protector for Water Pump/Motor

NEXT:NONE

NEXT:NONE