Temperature fuse and temperature control switch combination of application design

In order to protect the safety of all types of electrical equipment, To prevent the fire caused by failure. At present, most of the household appliances and power tools in the motor, Transformers, power distribution control box, precision instruments are used thermal protection components -Temperature fuse and temperature control switch.

This article describes two types of temperature protection devices: Temperature fuse and temperature control switch combination of applications, In order to better provide the thermal protection of electrical appliances, Temperature fuse and temperature control switch has its own advantages and functions. I need to better understand the basic performance of these two products, In order to ensure the correct use of the product.

1, the temperature fuse

(Thermal Links), also known as: thermal fuse (Thermal fuse); Is a connection in the circuit with a very precise and reliable temperature protection circuit of the one-time protection element. When the ambient temperature exceeds the rated temperature of the thermal fuse, So that the chemical heat beans to produce high-temperature rapid interrupt circuit, To avoid the application of overheating hazards. Temperature fuse, strictly speaking, Refers to the temperature of the temperature exceeds a certain temperature, The element that can disconnect the circuit in one body. After the thermal fuse disconnects the circuit, Its internal structure has been damaged, Even when the temperature is returned to the normal temperature, Also can not return, Unless a new thermal fuse is replaced.

Temperature fuse melting point temperature, That is, the fuse protection temperature of the circuit; Temperature fuse melting temperature of 65 ℃ ~ 320 ℃ a variety. For the protection of various types of electrical selection. In the selection of temperature before the insurance tube, Must understand and measure the need to protect the temperature and temperature of the location of the fuse temperature difference. In electrical and electronic equipment, The object to be protected is a motor, a transformer or the like. Its melting point temperature can be selected lower. Such as 70 ° C to 85 ° C. For power transistors. The melting point temperature is preferably 80C to 110C. And for electric cookers, electric heaters and other household appliances. Then depending on its distance from the heating area and placement of different. Selection of 100℃ ~ 300℃ range.

Temperature fuse widely used:

microwave ovens, drinking fountains, disinfection cabinet, electric iron, toaster, barbecue machine, coffee machine, kettle, dryer, refrigerators, electric water heaters and other electrical equipment.

2, the temperature protection switch

Temperature control switch is based on the temperature of the object to be controlled to determine the / power switch; According to its action principle is divided into: Bimetal, pressure and thermal ferrite type. Temperature control switch, is to reach a certain temperature (or temperature range) disconnect or turn on the circuit thermal protection components. Can be divided into automatic reset and manual reset. Either way, it can all be used multiple times.

The bimetal temperature control switch:

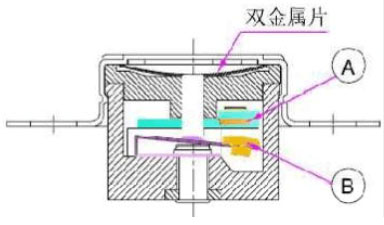

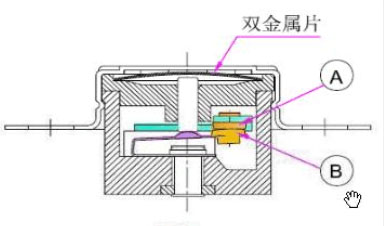

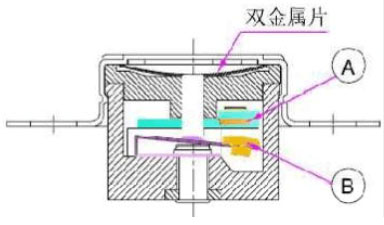

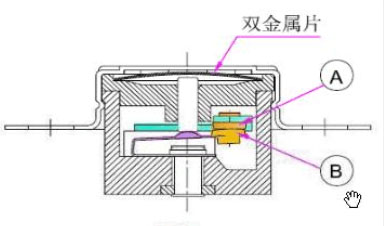

All kinds of metal has the characteristics of thermal expansion and contraction. The different metal with the temperature coefficient of expansion is not the same. Bimetal temperature control switch is based on this principle to work, The bimetal consists of an upper layer of "high-Mn and lower" Invar. The former expansion coefficient is several times that of the latter, Active layer and passive layer, respectively. At normal temperatures, the contacts of the contacts A and B of the copper piece and the spring piece are in contact with each other, The entire circuit is in the on state (Figure 1). When the temperature rises, the active layer expands more than the passive layer, The bimetal is bent downwards. When the temperature rises to a certain extent,The circuit is disconnected (Figure 2). Cooling to a certain extent bimetal recovery, the circuit connected.

Temperature protection switch commonly known as temperature relay. Its small size. Can be automatically reset, multiple use. It is widely used in air conditioners, refrigerators, washing machines, audio-visual equipment, hair dryer, electric heaters and all electrical tools on the motor, instrument for overheating protection.

3, temperature fuse and temperature control switch combination:

Any product has a life and failure. When the heating device temperature control switch fails, Temperature can not control, Equipment will be heated. It will burn out the product, causing a fire.In general, the temperature fuse and temperature control switch at the same time in series for double protection in the electrical appliances. At this time, the temperature control point of the temperature control switch can choose low for electrical over-temperature protection; While the temperature fuse is to choose a higher temperature control point, Used to cut off the total power supply when the internal temperature of the appliance rises. To prevent the occurrence of fire.

Design of Defrost Thermostat Design of Thermal Protector for Electric Water Heater

This article describes two types of temperature protection devices: Temperature fuse and temperature control switch combination of applications, In order to better provide the thermal protection of electrical appliances, Temperature fuse and temperature control switch has its own advantages and functions. I need to better understand the basic performance of these two products, In order to ensure the correct use of the product.

1, the temperature fuse

(Thermal Links), also known as: thermal fuse (Thermal fuse); Is a connection in the circuit with a very precise and reliable temperature protection circuit of the one-time protection element. When the ambient temperature exceeds the rated temperature of the thermal fuse, So that the chemical heat beans to produce high-temperature rapid interrupt circuit, To avoid the application of overheating hazards. Temperature fuse, strictly speaking, Refers to the temperature of the temperature exceeds a certain temperature, The element that can disconnect the circuit in one body. After the thermal fuse disconnects the circuit, Its internal structure has been damaged, Even when the temperature is returned to the normal temperature, Also can not return, Unless a new thermal fuse is replaced.

Temperature fuse melting point temperature, That is, the fuse protection temperature of the circuit; Temperature fuse melting temperature of 65 ℃ ~ 320 ℃ a variety. For the protection of various types of electrical selection. In the selection of temperature before the insurance tube, Must understand and measure the need to protect the temperature and temperature of the location of the fuse temperature difference. In electrical and electronic equipment, The object to be protected is a motor, a transformer or the like. Its melting point temperature can be selected lower. Such as 70 ° C to 85 ° C. For power transistors. The melting point temperature is preferably 80C to 110C. And for electric cookers, electric heaters and other household appliances. Then depending on its distance from the heating area and placement of different. Selection of 100℃ ~ 300℃ range.

Temperature fuse widely used:

microwave ovens, drinking fountains, disinfection cabinet, electric iron, toaster, barbecue machine, coffee machine, kettle, dryer, refrigerators, electric water heaters and other electrical equipment.

2, the temperature protection switch

Temperature control switch is based on the temperature of the object to be controlled to determine the / power switch; According to its action principle is divided into: Bimetal, pressure and thermal ferrite type. Temperature control switch, is to reach a certain temperature (or temperature range) disconnect or turn on the circuit thermal protection components. Can be divided into automatic reset and manual reset. Either way, it can all be used multiple times.

The bimetal temperature control switch:

All kinds of metal has the characteristics of thermal expansion and contraction. The different metal with the temperature coefficient of expansion is not the same. Bimetal temperature control switch is based on this principle to work, The bimetal consists of an upper layer of "high-Mn and lower" Invar. The former expansion coefficient is several times that of the latter, Active layer and passive layer, respectively. At normal temperatures, the contacts of the contacts A and B of the copper piece and the spring piece are in contact with each other, The entire circuit is in the on state (Figure 1). When the temperature rises, the active layer expands more than the passive layer, The bimetal is bent downwards. When the temperature rises to a certain extent,The circuit is disconnected (Figure 2). Cooling to a certain extent bimetal recovery, the circuit connected.

Temperature protection switch commonly known as temperature relay. Its small size. Can be automatically reset, multiple use. It is widely used in air conditioners, refrigerators, washing machines, audio-visual equipment, hair dryer, electric heaters and all electrical tools on the motor, instrument for overheating protection.

3, temperature fuse and temperature control switch combination:

Any product has a life and failure. When the heating device temperature control switch fails, Temperature can not control, Equipment will be heated. It will burn out the product, causing a fire.In general, the temperature fuse and temperature control switch at the same time in series for double protection in the electrical appliances. At this time, the temperature control point of the temperature control switch can choose low for electrical over-temperature protection; While the temperature fuse is to choose a higher temperature control point, Used to cut off the total power supply when the internal temperature of the appliance rises. To prevent the occurrence of fire.

Design of Defrost Thermostat Design of Thermal Protector for Electric Water Heater