Minimum temperature control switch size and parameters

China's lithium batteries are widely used in mobile phones, laptops, electric bicycles, electric vehicles, power tools, digital cameras and many other downstream areas. Power storage capacity in the lithium battery demand accounted for only about 2% While in mobile phones and notebook computers accounted for as high as 38% and 24%. Lithium battery overheating protection is also more and more important. These lithium battery current and voltage is relatively small. To facilitate the thermal protection of these lithium batteries, Small Bimetallic temperature switch to get rapid development.

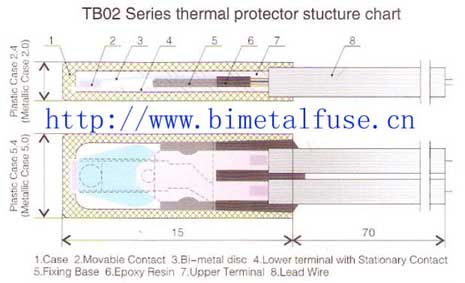

The current minimum temperature control switch is a square thermal protector, Product models are TB02 series, KW series, the standard product size: length * width * thick (11. 5 * 5. 0 * 2. 4) mm, Lead length can be customized according to customer requirements. Dongguan Yaxun minimum temperature control switch has two kinds of shell:

Molded Case Size: Length 15 * Width 5. 4 * Height 2.4

Steel Case Size: Length 11.5 * Width 5. 0 * Height 2.4

Performance

3. 1 Rated current

4A / DC12V, 3A / DC24V, 3A / AC115V, 2A / AC250V

3. 2 Disconnection temperature: 30 ℃ ~ 155 ℃ Reset temperature 20 ℃ ~ 110 ℃ (see drawing).

3. 3 Tensile test:The lead end of the product should be able to withstand greater than or equal to 20N tension, The wire is broken and slipped out.

3. 4 insulation voltage: a. Products in the disconnect between the lead should be able to withstand AC660V, Which lasted 1min without breakdown flashover phenomenon;

B. Product lead and insulation shell can withstand AC1800V, Lasted 1S without breakdown flashover phenomenon;

3. 5 Insulation resistance: Under normal conditions, The insulation resistance between the lead and the insulating housing is above 100MΩ. (Using the table for the DC500V megger)

3. 6 contact resistance: the product contact resistance should not be greater than 50mΩ.

3. 7 high temperature test:

A. product is placed higher than the rated operating temperature of 20 ℃ air environment maintained 96h;

B.5 min The limit temperature is 180 ° C

4.3.1 normally closed type

TB02-BB8D - Molded Case Product Model TB02-BB1D - Iron Case Product Model

XXX ℃ - Rated breaking temperature XXX ℃ - Rated breaking temperature

4.3.2 normally open type

TB02-KA8D - Molded Case Product Model TB02-KA1D - Iron Case Model

XXX ℃ - Rated breaking temperature XXX ℃ - Rated breaking temperature

5.Temperature parameter table:

| No. | Operating temperature | Reset temperature | No. | Operating temperature | Reset temperature |

| 30 | 30±3℃ | ≥20℃ | 95 | 95±5℃ | 70±15℃ |

| 35 | 35±3.5℃ | ≥25℃ | 100 | 100±5℃ | 70±15℃ |

| 40 | 40±4℃ | ≥30℃ | 105 | 105±5℃ | 75±15℃ |

| 45 | 45±4.5℃ | ≥33℃ | 110 | 110±5℃ | 75±15℃ |

| 50 | 50±5℃ | ≥35℃ | 115 | 115±5℃ | 80±15℃ |

| 55 | 55±5℃ | 42±6℃ | 120 | 120±5℃ | 85±15℃ |

| 60 | 60±5℃ | 45±8℃ | 125 | 125±5℃ | 85±15℃ |

| 65 | 65±5℃ | 48±10℃ | 130 | 130±5℃ | 90±15℃ |

| 70 | 70±5℃ | 50±12℃ | 135 | 135±5℃ | 95±15℃ |

| 75 | 75±5℃ | 53±14℃ | 140 | 140±5℃ | 100±15℃ |

| 80 | 80±5℃ | 55±15℃ | 145 | 145±5℃ | 100±15℃ |

| 85 | 85±5℃ | 60±15℃ | 150 | 150±℃ | 105±15℃ |

| 90 | 90±5℃ | 65±15℃ | 155 | 155±5℃ | 110±15℃ |

Product size and structure:

Technical Guide: <Ksd9700 Temperature Switch Inspection Rules>