Mechanical Thermostat Principle Graphic Description

Keywords: Mechanical Thermostat

As our lives get better and better, people are becoming more and more affluent, and the emphasis on life is becoming more and more strict. In the past, our families used traditional thermostats. With the continuous development, people have developed a mechanical thermostat, which is more convenient for us to live. Speaking of this kind of mechanical thermostat, do you know what the working principle of this mechanical thermostat is?

Introduction to mechanical thermostats:

Mechanical thermostats are suitable for indoor temperature control in industrial, commercial and residential buildings. The mechanical thermostat automatically controls the air conditioning equipment by detecting the indoor temperature and comparing it with the user set temperature to achieve the indoor constant temperature purpose. The main control equipments are: fan coil, heating, three- or two-line electric valve and building management system.

Mechanical temperature controller principle

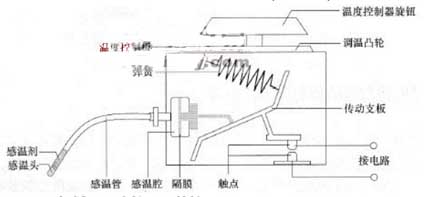

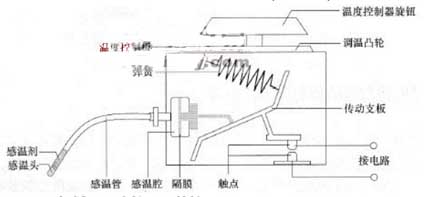

The mechanical temperature controller is actually a pressure (pneumatic) temperature controller, and its temperature control principle is shown in Figure 5-6.

When the temperature of the surface of the evaporator rises and exceeds the temperature set by the temperature controller knob, the pressure of the temperature sensitive agent in the temperature sensing tube increases. The diaphragm in the temperature sensing chamber presses the transmission support plate under the pressure to make the contacts open, the circuit is closed, the compressor starts to run, and the refrigerator starts to cool.

When the temperature of the surface of the evaporator gradually drops to a set value, the pressure of the temperature sensing agent in the temperature sensing tube decreases, and the contraction force of the spring is greater than the thrust generated by the diaphragm of the temperature sensing chamber to the transmission support plate. The drive plate is lifted up slightly under the contraction of the spring, causing the contact to open and the compressor to stop running.

The cooling temperature of the refrigerator is adjusted by adjusting the temperature controller knob. When the temperature controller knob is adjusted, the temperature controller knob drives the temperature control cam to rotate, so that the temperature control panel controls the tension of the spring.

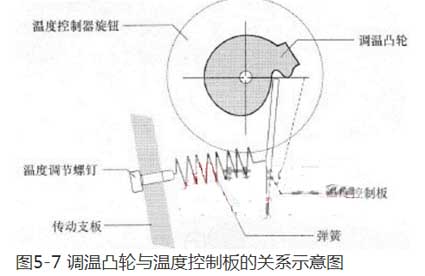

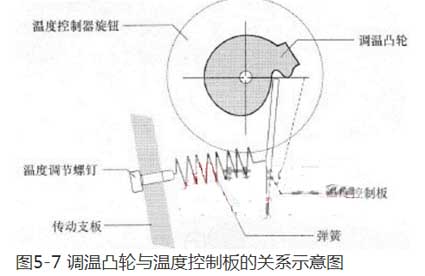

Figure 5-7 shows the relationship between the temperature control cam and the temperature control board of the temperature controller.

When the temperature controller knob is adjusted, the rotation of the knob actually drives the temperature adjustment cam to rotate, which causes the temperature control board to move forward or backward, thereby controlling the increase or decrease of the spring tension. If the spring pull force is large, it is necessary to increase the pressure of the temperature sensitive agent when the temperature of the evaporator is high, and generate a large driving force to move the support plate forward, push the contact to close, and the compressor will start working. This is how to increase the temperature of the refrigerator. Conversely, if the tension of the spring is small, when the temperature of the evaporator is slightly increased, the pressure generated by the temperature sensitive agent is sufficient to push the transmission support plate, the contacts are closed, and the compressor is started. This will lower the cooling temperature of the refrigerator.

The temperature adjustment screw in Figure 5-7 is used to adjust the temperature range. Turning the screw clockwise (right-handed) is equivalent to increasing the tension of the spring and raising the temperature control point. If the refrigerator has a non-stop failure, turn the adjustment screw clockwise for half a week or a week. Conversely, if the temperature adjustment screw (left-handed) is turned counterclockwise, it is equivalent to reducing the tension of the spring, so that the temperature control point is lowered. When the refrigerator has a failure that cannot be started regularly, the adjustment screw can be rotated counterclockwise for half a week or a week.

It is worth noting that the adjustment of the refrigerator temperature is directly related to its service life. The working hours and power consumption of the refrigerator are greatly affected by the surrounding environment. Usually in the summer, the surrounding ambient temperature is high, then it is best not to adjust the temperature inside the refrigerator too low. If the temperature inside the refrigerator is set too low, the refrigerator will be difficult to reach and maintain the set low temperature due to the influence of the ambient temperature, which makes the refrigerator compressor operate at high temperature for a long time. The wear of the piston and the cylinder is aggravated, and the insulation performance of the motor enameled wire is also lowered due to the high temperature. These conditions will greatly affect the performance of the refrigerator. At the same time, long-term cooling work will also increase power consumption.

When the ambient temperature is low in winter, the cooling temperature of the refrigerator can be set lower. If the temperature controller is still adjusted to a weak position at this time (the temperature control point is too high), the temperature difference between the inside and outside of the refrigerator is small, the heat dissipation is slow, and the refrigerator is not in the cooling state for a long time, which may cause the compressor to be difficult to start.

As our lives get better and better, people are becoming more and more affluent, and the emphasis on life is becoming more and more strict. In the past, our families used traditional thermostats. With the continuous development, people have developed a mechanical thermostat, which is more convenient for us to live. Speaking of this kind of mechanical thermostat, do you know what the working principle of this mechanical thermostat is?

Introduction to mechanical thermostats:

Mechanical thermostats are suitable for indoor temperature control in industrial, commercial and residential buildings. The mechanical thermostat automatically controls the air conditioning equipment by detecting the indoor temperature and comparing it with the user set temperature to achieve the indoor constant temperature purpose. The main control equipments are: fan coil, heating, three- or two-line electric valve and building management system.

Mechanical temperature controller principle

The mechanical temperature controller is actually a pressure (pneumatic) temperature controller, and its temperature control principle is shown in Figure 5-6.

Figure 5-6 Temperature control principle of mechanical temperature controller

Structurally, the mechanical temperature controller is mainly composed of a temperature sensor and a contact type micro switch. Among them, the temperature sensor is called a temperature and pressure conversion component, which is a closed capsule, which is mainly composed of a temperature sensing head, a temperature sensing tube and a temperature sensing chamber. According to the different form of temperature chamber, the temperature sensor can be divided into two types: wave tube type and diaphragm box type. The temperature sensor is located on the surface of the evaporator or inside the refrigerator box to induce the temperature in the refrigerator box. The temperature sensing tube is filled with a temperature sensing agent, and the temperature controller knob is used to set the cooling temperature of the refrigerator.When the temperature of the surface of the evaporator rises and exceeds the temperature set by the temperature controller knob, the pressure of the temperature sensitive agent in the temperature sensing tube increases. The diaphragm in the temperature sensing chamber presses the transmission support plate under the pressure to make the contacts open, the circuit is closed, the compressor starts to run, and the refrigerator starts to cool.

When the temperature of the surface of the evaporator gradually drops to a set value, the pressure of the temperature sensing agent in the temperature sensing tube decreases, and the contraction force of the spring is greater than the thrust generated by the diaphragm of the temperature sensing chamber to the transmission support plate. The drive plate is lifted up slightly under the contraction of the spring, causing the contact to open and the compressor to stop running.

The cooling temperature of the refrigerator is adjusted by adjusting the temperature controller knob. When the temperature controller knob is adjusted, the temperature controller knob drives the temperature control cam to rotate, so that the temperature control panel controls the tension of the spring.

Figure 5-7 shows the relationship between the temperature control cam and the temperature control board of the temperature controller.

When the temperature controller knob is adjusted, the rotation of the knob actually drives the temperature adjustment cam to rotate, which causes the temperature control board to move forward or backward, thereby controlling the increase or decrease of the spring tension. If the spring pull force is large, it is necessary to increase the pressure of the temperature sensitive agent when the temperature of the evaporator is high, and generate a large driving force to move the support plate forward, push the contact to close, and the compressor will start working. This is how to increase the temperature of the refrigerator. Conversely, if the tension of the spring is small, when the temperature of the evaporator is slightly increased, the pressure generated by the temperature sensitive agent is sufficient to push the transmission support plate, the contacts are closed, and the compressor is started. This will lower the cooling temperature of the refrigerator.

The temperature adjustment screw in Figure 5-7 is used to adjust the temperature range. Turning the screw clockwise (right-handed) is equivalent to increasing the tension of the spring and raising the temperature control point. If the refrigerator has a non-stop failure, turn the adjustment screw clockwise for half a week or a week. Conversely, if the temperature adjustment screw (left-handed) is turned counterclockwise, it is equivalent to reducing the tension of the spring, so that the temperature control point is lowered. When the refrigerator has a failure that cannot be started regularly, the adjustment screw can be rotated counterclockwise for half a week or a week.

It is worth noting that the adjustment of the refrigerator temperature is directly related to its service life. The working hours and power consumption of the refrigerator are greatly affected by the surrounding environment. Usually in the summer, the surrounding ambient temperature is high, then it is best not to adjust the temperature inside the refrigerator too low. If the temperature inside the refrigerator is set too low, the refrigerator will be difficult to reach and maintain the set low temperature due to the influence of the ambient temperature, which makes the refrigerator compressor operate at high temperature for a long time. The wear of the piston and the cylinder is aggravated, and the insulation performance of the motor enameled wire is also lowered due to the high temperature. These conditions will greatly affect the performance of the refrigerator. At the same time, long-term cooling work will also increase power consumption.

When the ambient temperature is low in winter, the cooling temperature of the refrigerator can be set lower. If the temperature controller is still adjusted to a weak position at this time (the temperature control point is too high), the temperature difference between the inside and outside of the refrigerator is small, the heat dissipation is slow, and the refrigerator is not in the cooling state for a long time, which may cause the compressor to be difficult to start.