Ksd9700, TB02 Miniature Temperature Control Switch Working Principle _ Structure and Application

Keywords: ksd9700 temperature control switch, TB02-BB8D, micro temperature control switch working principle

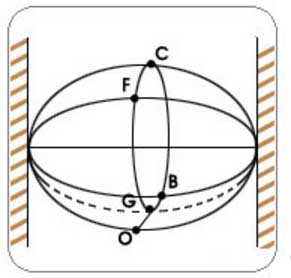

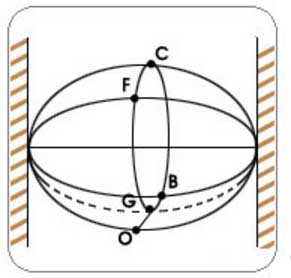

As shown below: As the temperature rises, the center of the bimetal slowly moves from the '0' point to the 'A' point. As the speed gets faster, the center of the bimetal turns from the 'B' point to the 'C' point when the 'B' point is reached. At this time, if the temperature drops, the center of the bimetal moves from the 'C' point to the E' point. When the 'F' point is reached, the center of the bimetal is instantaneously flipped again to the 'G' point (returned to its original shape). A bi-metal piece of a certain shape can be repeatedly operated in accordance with the Cycle of G -> A -> B -> C -> E -> F -> G. The temperature change from B->C is the open operating temperature (Open Temp). The temperature change from F -> G is the recovery temperature (Close Temp), and the difference between the off temperature and the recovery temperature is called depressor.

Using the bounce characteristics described above, the bimetal temperature control switch is called Thermostat.

Bimetal temperature control switch works:

The temperature-controlled switch bimetal is formed by combining two alloys with different thermal expansion coefficients on both sides, and then conducting the temperature on the surface of the aluminum cover of the temperature switch. The bimetal is converted to a mechanical motion by heating. The common low expansion layer is made of Ni-Fe alloy, while the high expansion layer is made of Ni-Mn-Cu alloy or Fe-Ni-Cr alloy. Different materials can be selected according to different expansion coefficients. The KSD9700 temperature switch is made of a bimetal into a dish shape. When the temperature rises and reaches the set temperature, the center of the bimetal plate of the temperature switch can be instantaneously turned over. When the temperature drops, the characteristics of the original position can be restored, and the element that converts the temperature into mechanical motion is made.

KSD9700 temperature control switch normally closed type working principle

working principle:

The KSD9700 temperature control switch is a closed thermostat developed by the Japanese Sumitomo BR-1 thermal bimetal. It is composed of butterfly-shaped high-sensitivity bimetal components, moving contacts, static contact pads, base, outer casing (iron shell) and high temperature resistant wires. The principle of heat generation after passing current and deformation at different temperatures. Because of the different thermal expansion coefficients of the two different alloys, the alloy tends to bend in one direction, and the contacts leave, and the electricity is cut off.

When the temperature drops to the re-set temperature, the contact automatically closes and returns to normal operation. The bending speed is proportional to the current passing through, thus protecting the electrical equipment.

product structure:

As shown below: As the temperature rises, the center of the bimetal slowly moves from the '0' point to the 'A' point. As the speed gets faster, the center of the bimetal turns from the 'B' point to the 'C' point when the 'B' point is reached. At this time, if the temperature drops, the center of the bimetal moves from the 'C' point to the E' point. When the 'F' point is reached, the center of the bimetal is instantaneously flipped again to the 'G' point (returned to its original shape). A bi-metal piece of a certain shape can be repeatedly operated in accordance with the Cycle of G -> A -> B -> C -> E -> F -> G. The temperature change from B->C is the open operating temperature (Open Temp). The temperature change from F -> G is the recovery temperature (Close Temp), and the difference between the off temperature and the recovery temperature is called depressor.

Using the bounce characteristics described above, the bimetal temperature control switch is called Thermostat.

Bimetal temperature control switch works:

The temperature-controlled switch bimetal is formed by combining two alloys with different thermal expansion coefficients on both sides, and then conducting the temperature on the surface of the aluminum cover of the temperature switch. The bimetal is converted to a mechanical motion by heating. The common low expansion layer is made of Ni-Fe alloy, while the high expansion layer is made of Ni-Mn-Cu alloy or Fe-Ni-Cr alloy. Different materials can be selected according to different expansion coefficients. The KSD9700 temperature switch is made of a bimetal into a dish shape. When the temperature rises and reaches the set temperature, the center of the bimetal plate of the temperature switch can be instantaneously turned over. When the temperature drops, the characteristics of the original position can be restored, and the element that converts the temperature into mechanical motion is made.

KSD9700 temperature control switch normally closed type working principle

working principle:

The KSD9700 temperature control switch is a closed thermostat developed by the Japanese Sumitomo BR-1 thermal bimetal. It is composed of butterfly-shaped high-sensitivity bimetal components, moving contacts, static contact pads, base, outer casing (iron shell) and high temperature resistant wires. The principle of heat generation after passing current and deformation at different temperatures. Because of the different thermal expansion coefficients of the two different alloys, the alloy tends to bend in one direction, and the contacts leave, and the electricity is cut off.

When the temperature drops to the re-set temperature, the contact automatically closes and returns to normal operation. The bending speed is proportional to the current passing through, thus protecting the electrical equipment.

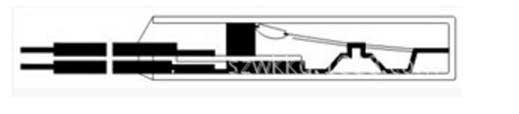

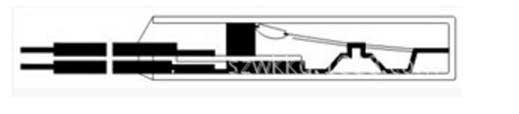

product structure:

1. Iron shell 2. Insulation layer 3, lug 4, gasket 5, base 6, moving contact 7, moving contact 8, bimetal 9, sealant, 10, lead

Scope of application:

This product is suitable for all kinds of motors, induction cookers, hand warmers, vacuum cleaners, soymilk machines, ballasts, washing machine motors, air conditioner fan motors, transformers, ballasts, induction cookers, electric heating belts, water pump exhaust fans, batteries, electric Various electric heating products such as tools.

Product advantages:

It has the characteristics of fast temperature sensing, rapid action, precise temperature control, large control current, small resistance, reliability, crispness, no arcing, small size and long service life. It can replace SENSATA 17AM 7AM, South Korea SEK ST-22 and other foreign products.

Dimensions:

KSD9700A 18.5*7*3.5mm (PBT high temperature resistant plastic case, same size as Korean SEKI ST-22)

KSD9700A-1 20mm*7.6mm*4mm (PBT high temperature plastic case)

KSD9700B 20mm*7.4mm*3.8mm (metal case)

KSD9700C 20mm*8.5mm*5mm (ceramic casing) wire: PVC wire or high temperature silicone wire.

This product is suitable for all kinds of motors, induction cookers, hand warmers, vacuum cleaners, soymilk machines, ballasts, washing machine motors, air conditioner fan motors, transformers, ballasts, induction cookers, electric heating belts, water pump exhaust fans, batteries, electric Various electric heating products such as tools.

Product advantages:

It has the characteristics of fast temperature sensing, rapid action, precise temperature control, large control current, small resistance, reliability, crispness, no arcing, small size and long service life. It can replace SENSATA 17AM 7AM, South Korea SEK ST-22 and other foreign products.

Dimensions:

KSD9700A 18.5*7*3.5mm (PBT high temperature resistant plastic case, same size as Korean SEKI ST-22)

KSD9700A-1 20mm*7.6mm*4mm (PBT high temperature plastic case)

KSD9700B 20mm*7.4mm*3.8mm (metal case)

KSD9700C 20mm*8.5mm*5mm (ceramic casing) wire: PVC wire or high temperature silicone wire.