Bimetal Thermostat Ksd9700, TB02, 17AM Wiring Diagram

Keywords: ksd9700, TB02, 17AM, Bimetal Thermostat

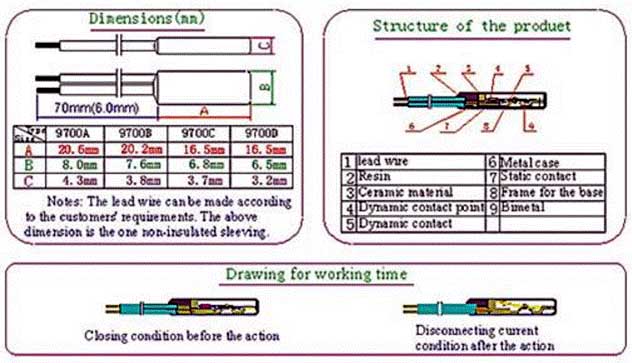

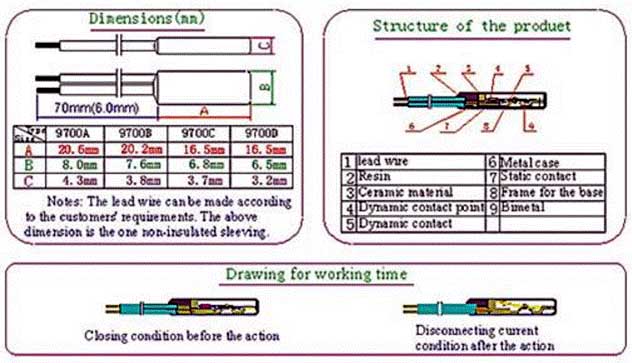

KSD9700 series Bimetal Thermostat (thermal protector) is composed of dish-shaped high sensitive bimetal, moving contact, static contact piece, fixed base, outer casing and temperature resistant wire. During operation, the bimetal is in a free state, the moving contact and the static contact are closed, and the circuit is turned on. When the temperature rises to the action temperature of the thermal protector due to the failure of the electric apparatus. The bimetal is heated to generate internal stress and acts quickly. Pushing the movable contact away from the static contact piece breaks the circuit, thereby cutting off the faulty electrical power source to protect the electrical appliance.

When the temperature of the protected appliance drops to the rated reset temperature value of the thermal protector, the bimetal returns to the initial state and the contact is closed, and the electrical appliance resumes normal operation. The product has the advantages of small resistance, fast temperature sensing, rapid action, safety and reliability, and small volume.

Structure and application

The KSD9700 series is a thermostat with a bimetal as a temperature sensing element. When the appliance is working normally, the bimetal is in a free state and the contacts are in a closed/disconnected state. When the temperature rises to the operating temperature value, the bimetal element is heated to generate internal stress and acts quickly, opening/closing the contact, cutting off/closing the circuit, thereby providing thermal protection. When the temperature drops to the re-set temperature, the contact automatically closes/opens and resumes normal operation. Widely used in household electrical appliances and electrical equipment, such as washing machine motors, air conditioning fan motors, transformers, ballasts, electric appliances, etc.

Characteristic advantage

Small internal resistance (<50mΩ);

Fast temperature, fast action, safe and reliable;

Small size for easy installation;

Different lengths or specifications of leads can be customized according to customer requirements;

There are two types of normally closed and normally open.

KSD9700 series Bimetal Thermostat product advantages

(1) Small size, easy to install

(2) Quick-acting bimetal, fast response

(3) Life expectancy is up to 10,000 times or more

(4) Anti-vacuum dipping process

(5) Can replace SENSATA 17AM 7AM, South Korea SEK ST-22 and other foreign products

KSD9700 Series Bimetal Thermostat Precautions

(1) When using contact temperature sensing, the product should be placed close to the mounting surface of the controlled appliance.

(2) Do not crush or deform the plastic or metal casing during installation to avoid affecting performance.

(3) Metal casing products with insulated jackets should not be removed or crushed during installation to avoid leakage and ensure safe use.

(4) The product should be used in a circuit with a current of no more than 5A. The copper core should be connected with a 0.4-0.75mm2 wire.

(5) The product should be stored in a place where the relative humidity is less than 90% and the ambient temperature is below 40 °C, which is ventilated, clean, dry and free of corrosive gases.

KSD9700 series Bimetal Thermostat (thermal protector) is composed of dish-shaped high sensitive bimetal, moving contact, static contact piece, fixed base, outer casing and temperature resistant wire. During operation, the bimetal is in a free state, the moving contact and the static contact are closed, and the circuit is turned on. When the temperature rises to the action temperature of the thermal protector due to the failure of the electric apparatus. The bimetal is heated to generate internal stress and acts quickly. Pushing the movable contact away from the static contact piece breaks the circuit, thereby cutting off the faulty electrical power source to protect the electrical appliance.

When the temperature of the protected appliance drops to the rated reset temperature value of the thermal protector, the bimetal returns to the initial state and the contact is closed, and the electrical appliance resumes normal operation. The product has the advantages of small resistance, fast temperature sensing, rapid action, safety and reliability, and small volume.

Structure and application

The KSD9700 series is a thermostat with a bimetal as a temperature sensing element. When the appliance is working normally, the bimetal is in a free state and the contacts are in a closed/disconnected state. When the temperature rises to the operating temperature value, the bimetal element is heated to generate internal stress and acts quickly, opening/closing the contact, cutting off/closing the circuit, thereby providing thermal protection. When the temperature drops to the re-set temperature, the contact automatically closes/opens and resumes normal operation. Widely used in household electrical appliances and electrical equipment, such as washing machine motors, air conditioning fan motors, transformers, ballasts, electric appliances, etc.

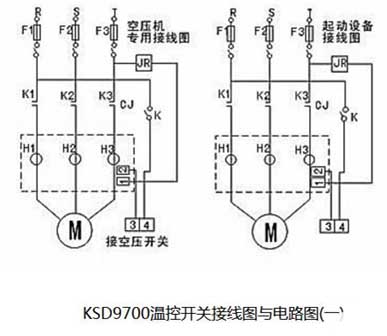

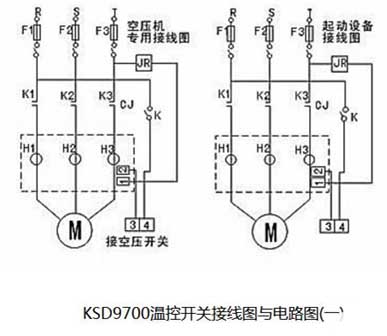

KSD9700 temperature control switch wiring diagram and circuit diagram

Characteristic advantage

Small internal resistance (<50mΩ);

Fast temperature, fast action, safe and reliable;

Small size for easy installation;

Different lengths or specifications of leads can be customized according to customer requirements;

There are two types of normally closed and normally open.

KSD9700 series Bimetal Thermostat product advantages

(1) Small size, easy to install

(2) Quick-acting bimetal, fast response

(3) Life expectancy is up to 10,000 times or more

(4) Anti-vacuum dipping process

(5) Can replace SENSATA 17AM 7AM, South Korea SEK ST-22 and other foreign products

KSD9700 Series Bimetal Thermostat Precautions

(1) When using contact temperature sensing, the product should be placed close to the mounting surface of the controlled appliance.

(2) Do not crush or deform the plastic or metal casing during installation to avoid affecting performance.

(3) Metal casing products with insulated jackets should not be removed or crushed during installation to avoid leakage and ensure safe use.

(4) The product should be used in a circuit with a current of no more than 5A. The copper core should be connected with a 0.4-0.75mm2 wire.

(5) The product should be stored in a place where the relative humidity is less than 90% and the ambient temperature is below 40 °C, which is ventilated, clean, dry and free of corrosive gases.