KUOYUH Overload protection Manufacturer

- PRODUCT DETAIL

Overload protection by sensing temperature and current to protect the compressor. Overload is basically composed of a normally closed contact and bimetallic element. Overload protection is assembled outside of the compressor, and direct contact with the compressor housing and compressor windings connected in series. If the compressor does not start for some reason, the overload stall current will cause rapid heat the bimetal element bent, cause rapid jump, cut off the current flowing through the compressor to protect the compressor. Similarly, if the compressor motor winding temperature compressor cause abnormal heat is too high, the protector will heat and jump, so as to protect the compressor. As long as the cause of the malfunction does not exclude, in the case of compressor overload, again and again with the action of the bimetal element and open stop.

Use ohmmeter for testing

1. If the overload protection device is disconnected, then let it cool to room temperature (closed) continue to measure.

2. Although capable of continuous observation of work overload, however, to confirm that the parts are there hard work according to specifications.

3. If you are not sure whether there is a problem overload, replace parts of the same

Motor overload protection device 88 series breakers UL / TUV / CE / CSA certific

specifications.

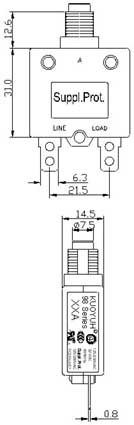

Rated Current : 0.5A~30A

Rated Voltage : 125/250VAC 50VDC 50~60Hz

Open Capacity: 1,000A×125VAC

20A×250VAC

Hi-pot Test: 1,500V/min

Overload current : 10 times of rated current

Min voltage: less than 0.25V

Reset time : in 60 seconds

Insulation resistance : more than 500VDC × 100MΩ

Terminal temp : 100 % test under 25°C

temperature rise less than 25°C

Life test: 125VAC × 150 % current, over 500 cycles.

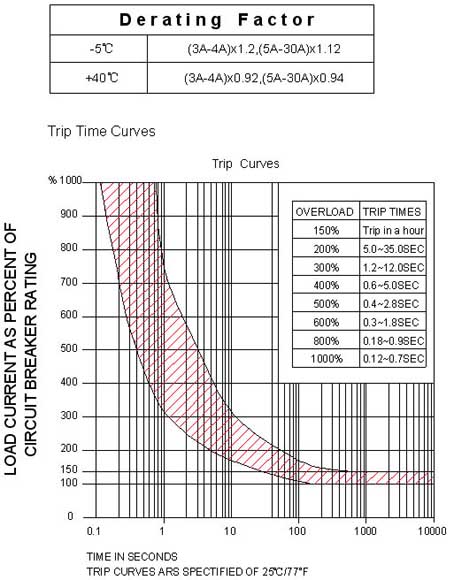

Test standard(25°C) of this circuit breaker:

100% rated current: No trip Off

150% rated current: trip off in 1 hour

200% rated current: trip off in 40 minutes

300% rated current: trip off in 10 seconds

Product Certification: UL / TUV / CE / CB / RoHS

Use ohmmeter for testing

1. If the overload protection device is disconnected, then let it cool to room temperature (closed) continue to measure.

2. Although capable of continuous observation of work overload, however, to confirm that the parts are there hard work according to specifications.

3. If you are not sure whether there is a problem overload, replace parts of the same

Motor overload protection device 88 series breakers UL / TUV / CE / CSA certific

specifications.

Rated Current : 0.5A~30A

Rated Voltage : 125/250VAC 50VDC 50~60Hz

Open Capacity: 1,000A×125VAC

20A×250VAC

Hi-pot Test: 1,500V/min

Overload current : 10 times of rated current

Min voltage: less than 0.25V

Reset time : in 60 seconds

Insulation resistance : more than 500VDC × 100MΩ

Terminal temp : 100 % test under 25°C

temperature rise less than 25°C

Life test: 125VAC × 150 % current, over 500 cycles.

Test standard(25°C) of this circuit breaker:

100% rated current: No trip Off

150% rated current: trip off in 1 hour

200% rated current: trip off in 40 minutes

300% rated current: trip off in 10 seconds

Product Certification: UL / TUV / CE / CB / RoHS