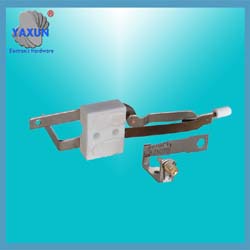

KST Ceramics High temperature Electric iron thermal limit switch

- PRODUCT DETAIL

KST thermostat's hot bimetal is a kind of composite metal. It is generally composed of two or more layers of metals or alloys with different expansion coefficients that are firmly compounded along the entire contact surface. Its working principle is that when the temperature changes, the shape of the hot bimetal will change, so that the KST thermostat can well control the temperature jump and recovery.

There are two forms of failure of the KST thermostat thermal bimetal:

Zero-drift failure and cracking failure caused by hot bimetal.

I. Zero-point drift refers to the sudden or recovery action of the hot bimetal at a temperature higher or lower than the required temperature. There are three main cases of zero drift caused by thermal bimetals:

1. Unsatisfactory thermal bimetallic performance parameters lead to zero drift.

2. Unsatisfactory dimensional parameters of thermal bimetals cause zero drift.

3. The separation between the layers of the hot bimetal causes zero drift.

II. Thermal cracking failure of the bimetal, the bimetal thermal syndiotactic layer was separated. When the crack propagation force of the thermal bimetal is greater than the interfacial force of the thermal bimetal, the thermal bimetal will crack and fail.

Electric iron thermal limit switch Technical Parameters:

1. Electrical parameters: 16A 250V ~; 20A 125V ~;

2. Operating temperature range: 0 ℃ ~ 250 ℃ optional;

3. Electrical strength: 2000V ~ 1min no breakdown, reliable product action altogether, do not pull the arc, long life, low radio interference, temperature control accurate;

4. Contact resistance: ≤50mΩ;

5. Insulation resistance: ≥5MΩ;

6. Leakage current: ≤0.25mA;

7. Rotary axis: torque 1.5N · m or more, the initial value of the test temperature within ± 1 ℃;

7. Life: 100,000 cycles;

8. Thermostat axis rotation angle: 0 ° to 310 ° optional;

9. Terminals: according to the actual needs of the customer ac households have 0.8 and 6.3 * 4.8 * 0.8, etc. in line with the national standard selection of terminals.

10. The UL.CUL, VDE, CE, TUV, CEMC, ROHS certification

There are two forms of failure of the KST thermostat thermal bimetal:

Zero-drift failure and cracking failure caused by hot bimetal.

I. Zero-point drift refers to the sudden or recovery action of the hot bimetal at a temperature higher or lower than the required temperature. There are three main cases of zero drift caused by thermal bimetals:

1. Unsatisfactory thermal bimetallic performance parameters lead to zero drift.

2. Unsatisfactory dimensional parameters of thermal bimetals cause zero drift.

3. The separation between the layers of the hot bimetal causes zero drift.

II. Thermal cracking failure of the bimetal, the bimetal thermal syndiotactic layer was separated. When the crack propagation force of the thermal bimetal is greater than the interfacial force of the thermal bimetal, the thermal bimetal will crack and fail.

Electric iron thermal limit switch Technical Parameters:

1. Electrical parameters: 16A 250V ~; 20A 125V ~;

2. Operating temperature range: 0 ℃ ~ 250 ℃ optional;

3. Electrical strength: 2000V ~ 1min no breakdown, reliable product action altogether, do not pull the arc, long life, low radio interference, temperature control accurate;

4. Contact resistance: ≤50mΩ;

5. Insulation resistance: ≥5MΩ;

6. Leakage current: ≤0.25mA;

7. Rotary axis: torque 1.5N · m or more, the initial value of the test temperature within ± 1 ℃;

7. Life: 100,000 cycles;

8. Thermostat axis rotation angle: 0 ° to 310 ° optional;

9. Terminals: according to the actual needs of the customer ac households have 0.8 and 6.3 * 4.8 * 0.8, etc. in line with the national standard selection of terminals.

10. The UL.CUL, VDE, CE, TUV, CEMC, ROHS certification