China UL_ VDE_ TUV_ EK_ PSE Certification Online Electrical Fuse Sale Company

- PRODUCT DETAIL

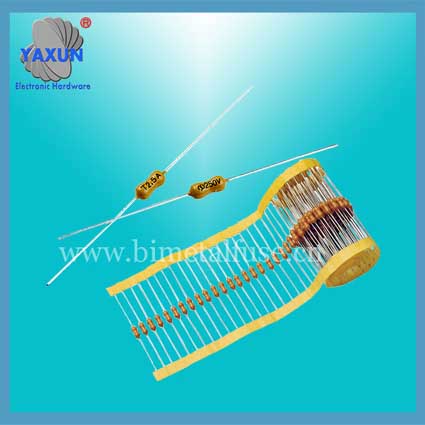

Basic composition of fuse

A general fuse consists of three parts: The first is the melt part, which is the core of the fuse and cuts off the current when it blows.The fuses of the same type and same specification fuse must have the same material, the same geometric size, and the resistance value as small as possible and consistent. The most important thing is to have consistent fuse characteristics. Household fuses are often made of lead-antimony alloys.

The second is the electrode part, usually there are two, it is an important part of the melt and circuit connection. It must have good electrical conductivity and should not produce significant mounting contact resistance.

The third is the bracket part, the fuse of the fuse is generally thin and soft. The role of the bracket is to fix the melt and make the three parts rigid and easy to install and use. It must have good mechanical strength, insulation, heat resistance and flame retardancy, and should not cause cracks, deformation, combustion and short circuits in use.

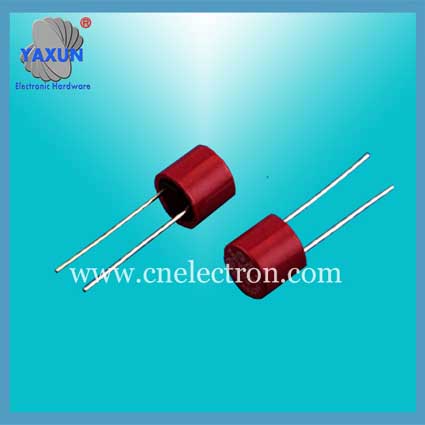

Fuse arc extinguishing device

The fuses used in power circuits and high-power equipment include not only the three parts of general fuses, but also arc extinguishing devices.

Because the circuit protected by this type of fuse not only has a large working current, but also the voltage across the fuse is very high when the fuse is blown, often the melt has melted (fused) or even vaporized, but the current is not cut off.

The reason is that under the action of voltage and current at the moment of fusing, arcing occurs between the two electrodes of the fuse.

This arc extinguishing device must have strong insulation and good thermal conductivity, and be negatively charged. Quartz sand is a commonly used arc extinguishing material.

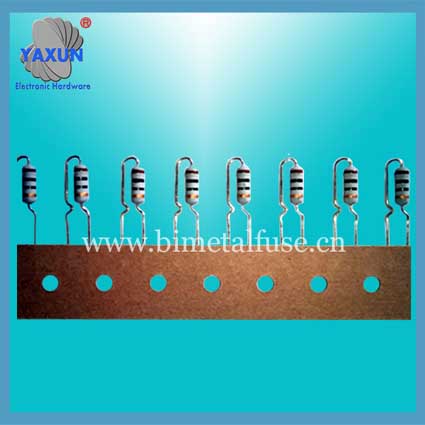

Fuse device

In addition, some fuses have a blow-out indicator. Its function is that when the fuse operates (fuse), it will have a certain appearance change, which is easy to be found by maintenance personnel. For example: glow, change color, pop solid indicator, etc.

Functional Characteristics

Approvals(○ Pending ● Approvals)

A general fuse consists of three parts: The first is the melt part, which is the core of the fuse and cuts off the current when it blows.The fuses of the same type and same specification fuse must have the same material, the same geometric size, and the resistance value as small as possible and consistent. The most important thing is to have consistent fuse characteristics. Household fuses are often made of lead-antimony alloys.

The second is the electrode part, usually there are two, it is an important part of the melt and circuit connection. It must have good electrical conductivity and should not produce significant mounting contact resistance.

The third is the bracket part, the fuse of the fuse is generally thin and soft. The role of the bracket is to fix the melt and make the three parts rigid and easy to install and use. It must have good mechanical strength, insulation, heat resistance and flame retardancy, and should not cause cracks, deformation, combustion and short circuits in use.

Fuse arc extinguishing device

The fuses used in power circuits and high-power equipment include not only the three parts of general fuses, but also arc extinguishing devices.

Because the circuit protected by this type of fuse not only has a large working current, but also the voltage across the fuse is very high when the fuse is blown, often the melt has melted (fused) or even vaporized, but the current is not cut off.

The reason is that under the action of voltage and current at the moment of fusing, arcing occurs between the two electrodes of the fuse.

This arc extinguishing device must have strong insulation and good thermal conductivity, and be negatively charged. Quartz sand is a commonly used arc extinguishing material.

Fuse device

In addition, some fuses have a blow-out indicator. Its function is that when the fuse operates (fuse), it will have a certain appearance change, which is easy to be found by maintenance personnel. For example: glow, change color, pop solid indicator, etc.

| Breaking Capacity | Material | Operating Temperature | Soldering conditions |

|

VDE:35A or 10ln whichever is greater(250mA-6.3A) UL:50 amperes at 125V/250V AC (250mA-10A) |

Fuse body –glass tube End cap --nickel plated brass Pigtail--tin plated copper on nickel plated brass cap |

-40℃~+125℃ |

Wave solder:260℃,≤5S Hand solder: 360℃,≤1S |

Functional Characteristics

| Testing current | Blow Time | |

| Min | Max | |

| 150% | 1 hour | - |

| 210% | 100ms | 1800s |

| 275% | 10ms | 3s |

| 400% | 3ms | 300ms |

| 1000% | - | 20ms |

Approvals(○ Pending ● Approvals)

|

Current Rating |

Voltage Rating |

Norminal Melting I2T(A2sec) |

Approvals | ||||

| VDE | CQC | UL | PSE | KC | |||

| 250mA | 125V/250V | 0.14 | ● | ● | ● | ● | |

| 300mA | 125V/250V | 0.20 | ● | ||||

| 315mA | 125V/250V | 0.23 | ● | ● | ● | ● | |

| 350mA | 125V/250V | 0.27 | ● | ||||

| 400mA | 125V/250V | 0.38 | ● | ||||

| 500mA | 125V/250V | 0.50 | ● | ● | ● | ● | |

| 600mA | 125V/250V | 0.72 | ● | ||||

| 630mA | 125V/250V | 0.9 | ● | ● | ● | ● | |

| 750mA | 125V/250V | 1.2 | ● | ||||

| 800mA | 125V/250V | 1.6 | ● | ● | ● | ● | |

| 1A | 125V/250V | 2.4 | ● | ● | ● | ● | ● |

| 1.25A | 125V/250V | 3.5 | ● | ● | ● | ● | ● |

| 1.5A | 125V/250V | 4 | ● | ● | |||

| 1.6A | 125V/250V | 7.2 | ● | ● | ● | ● | ● |

| 2A | 125V/250V | 9.6 | ● | ● | ● | ● | ● |

| 2.5A | 125V/250V | 16 | ● | ● | ● | ● | ● |

| 3A | 125V/250V | 17.8 | ● | ● | |||

| 3.15A | 125V/250V | 22 | ● | ● | ● | ● | ● |

| 3.5A | 125V/250V | 28 | ● | ● | |||

| 4A | 125V/250V | 45 | ● | ● | ● | ● | ● |

| 5A | 125V/250V | 62 | ● | ● | ● | ● | ● |

| 6A | 125V/250V | 70 | ● | ||||

| 6.3A | 125V/250V | 72 | ● | ● | ● | ● | |

| 7A | 125V/250V | 88 | ● | ||||

| 8A | 125V/250V | 110 | ○ | ○ | ● | ○ | |

| 10A | 125V/250V | 144 | ○ | ○ | ● | ○ | |