high Temperature Axial Leaded glass Cooker thermistor

- PRODUCT DETAIL

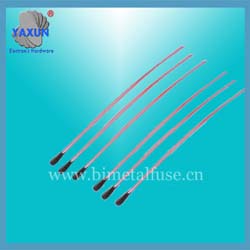

The glass-encapsulated NTC thermistor has high stability and high accuracy. Compared with traditional thermistors encapsulated with epoxy resin, this product has a wider temperature test range, longer lasting stability, smaller size and shorter response time. In addition, we also provide you with 2 types of lead-insulated thermistors. One type of thermistor has a Teflon sleeve for insulation. The lead of another thermistor is not only covered with a Teflon sleeve, but also sealed with an epoxy resin between the temperature sensing head and the sleeve, which plays a waterproof and more thorough insulation role.

Glass-sealed thermistors are mainly used for temperature compensation. Thermistors are available in several material packages, such as epoxy, SMD, glass, etc. The main characteristics of glass seal in NTC are high temperature and humidity resistance, but compared to other packages, the response speed is a bit slower, about ten seconds or so! Other brief descriptions are as follows

1. It is made by the process technology combining the ceramic process and the semiconductor process, and the pure glass packaging structure is drawn out axially at both ends.

2. Application:

• Temperature control and temperature detection of household appliances (such as air conditioners, microwave ovens, electric fans, electric heating stoves, etc.)

• Temperature detection or temperature compensation of office automation equipment (such as copiers, printers, etc.)

• Temperature control and inspection of industrial, medical, environmental protection, meteorology, food processing equipment

• Liquid level indication and flow measurement

•cell phone battery

• Temperature compensation of instrument coils, integrated circuits, quartz crystal oscillators and thermocouples

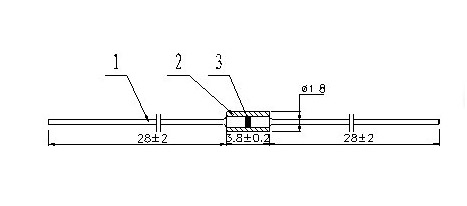

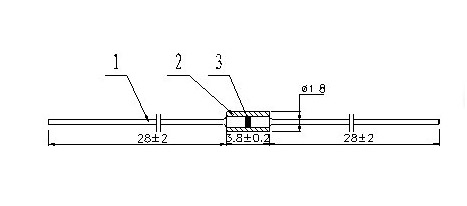

A: Size chart

Product Applications:

1: induction cooker, electric pressure cookers, rice cookers, electric oven, disinfection cabinet, water dispenser, microwave ovens, electric heaters and other appliances temperature control and temperature sensing.

2: office automation equipment (such as copiers, printers, etc.) to compensate for temperature detection and temperature.

3: temperature industrial, medical, environmental, weather, food processing equipment, control and testing.

4: rechargeable battery pack and charger temperature protection.

5 meter coils, integrated circuits, quartz crystal oscillator and thermocouple temperature compensation.

II: Product Features:

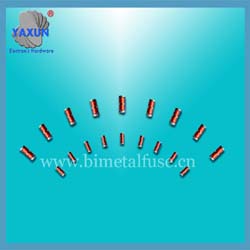

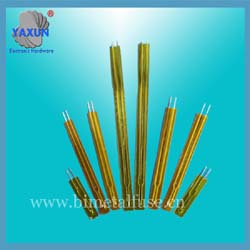

1: MF58 series of products for axial leaded glass encapsulated form

2: good stability, high reliability

3: Wide range of resistance: 1KΩ ~ 1000KΩ

4: Resistance and B value of high accuracy

5: As the purchase of glass packaging, can be used in harsh environments such as high temperature and high temperature

6: Small, rugged, easy to automate installation

7: Operating temperature range -40 ℃ ~ + 300 ℃

8: Rated power: ≤50mW

9: Heat induction fast, high sensitivity

Four: Model Description

MF 58 103 F 3950

① ② ③ ④ ⑤

①MF ¬-- negative temperature coefficient (NTC) thermistor Code.

②58-- glass encapsulated thermistor.

③103 - thermistor nominal resistance, indicating that the nominal resistance of the resistance: 10 × 103 (Ω).

Error ④F-- resistance value (accuracy) is: F = ± 1%, G = ± 2%, H = ± 3%, J = ± 5%

⑤3950-- thermal resistance index (material factor) B is: 395 × 10 (K)

Note: according to customer requirements, provide different R-values, B values of precision, customization.

NTC thermistor measurements must note the following:

1) can not be measured in the air, the larger the difference in air temperature measurement inaccurate, resulting in dispersion in the accuracy.

2) using high-precision measurements of the bath, measured after NTC into the bath after bath temperature must be stabilized before measurement.

3) Measure the voltage as low as possible in order to reduce measurement errors due to self-heating NTC.

4) When the temperature measurement, the required temperature of the bath thermometer to be corrected, check.

Five: MF58 Series Model Specification

Glass-sealed thermistors are mainly used for temperature compensation. Thermistors are available in several material packages, such as epoxy, SMD, glass, etc. The main characteristics of glass seal in NTC are high temperature and humidity resistance, but compared to other packages, the response speed is a bit slower, about ten seconds or so! Other brief descriptions are as follows

1. It is made by the process technology combining the ceramic process and the semiconductor process, and the pure glass packaging structure is drawn out axially at both ends.

2. Application:

• Temperature control and temperature detection of household appliances (such as air conditioners, microwave ovens, electric fans, electric heating stoves, etc.)

• Temperature detection or temperature compensation of office automation equipment (such as copiers, printers, etc.)

• Temperature control and inspection of industrial, medical, environmental protection, meteorology, food processing equipment

• Liquid level indication and flow measurement

•cell phone battery

• Temperature compensation of instrument coils, integrated circuits, quartz crystal oscillators and thermocouples

A: Size chart

Product Applications:

1: induction cooker, electric pressure cookers, rice cookers, electric oven, disinfection cabinet, water dispenser, microwave ovens, electric heaters and other appliances temperature control and temperature sensing.

2: office automation equipment (such as copiers, printers, etc.) to compensate for temperature detection and temperature.

3: temperature industrial, medical, environmental, weather, food processing equipment, control and testing.

4: rechargeable battery pack and charger temperature protection.

5 meter coils, integrated circuits, quartz crystal oscillator and thermocouple temperature compensation.

II: Product Features:

1: MF58 series of products for axial leaded glass encapsulated form

2: good stability, high reliability

3: Wide range of resistance: 1KΩ ~ 1000KΩ

4: Resistance and B value of high accuracy

5: As the purchase of glass packaging, can be used in harsh environments such as high temperature and high temperature

6: Small, rugged, easy to automate installation

7: Operating temperature range -40 ℃ ~ + 300 ℃

8: Rated power: ≤50mW

9: Heat induction fast, high sensitivity

Four: Model Description

MF 58 103 F 3950

① ② ③ ④ ⑤

①MF ¬-- negative temperature coefficient (NTC) thermistor Code.

②58-- glass encapsulated thermistor.

③103 - thermistor nominal resistance, indicating that the nominal resistance of the resistance: 10 × 103 (Ω).

Error ④F-- resistance value (accuracy) is: F = ± 1%, G = ± 2%, H = ± 3%, J = ± 5%

⑤3950-- thermal resistance index (material factor) B is: 395 × 10 (K)

Note: according to customer requirements, provide different R-values, B values of precision, customization.

NTC thermistor measurements must note the following:

1) can not be measured in the air, the larger the difference in air temperature measurement inaccurate, resulting in dispersion in the accuracy.

2) using high-precision measurements of the bath, measured after NTC into the bath after bath temperature must be stabilized before measurement.

3) Measure the voltage as low as possible in order to reduce measurement errors due to self-heating NTC.

4) When the temperature measurement, the required temperature of the bath thermometer to be corrected, check.

Five: MF58 Series Model Specification

| Model | Rated resistance(R25) | B Value |

work Temperature |

Dissipation factor(mW/℃) |

Thermal time constant(S) |

|

|

Resistance (KΩ) |

Tolerance (± %) |

Nominal value (K) |

||||

| MF58-202-3435 | 2 |

±1% ±2% ±3% ±5% |

3435 |

-40℃ ~ +250℃ |

≥2.0 Still air |

≤12 Still air |

| MF58-502-3470 | 5 | 3470 | ||||

| MF58-103-3435 | 10 | 3435 | ||||

| MF58-103-3600 | 10 | 3600 | ||||

| MF58-103-3700 | 10 | 3700 | ||||

| MF58-103-3950 | 10 | 3950 | ||||

| MF58-103-4100 | 10 | 4100 | ||||

| MF58-203-3950 | 20 | 3950 | ||||

| MF58-233-3950 | 23 | 3950 | ||||

| MF58-303-3950 | 30 | 3950 | ||||

| MF58-40.27-3979 | 40.27 | 3979 | ||||

| MF58-473-3950 | 47 | 3950 | ||||

| MF58-503-3950 | 50 | 3950 | ||||

| MF58-503-4050 | 50 | 4050 | ||||

| MF58-104-3899 | 100 | 3899 | ||||

| MF58-104-3950 | 100 | 3950 | ||||

| MF58-104-3990 | 100 | 3990 | ||||

| MF58-104-4050 | 100 | 4050 | ||||

| MF58-104-4200 | 100 | 4200 | ||||

| MF58-204-4260 | 200 | 4260 |

-40℃ ~ +300℃ |

|||

| MF58-504-4260 | 500 | 4260 | ||||

| MF58-504-4400 | 500 | 4400 | ||||

| MF58-105-4400 | 1000 | 4400 | ||||