Working Principle of Several Motor Protectors

Guide: Protector, an automatic alarm or error detection alarm device for implementing motor equipment. A motor protector is naturally a device for self-protecting the motor. So how does the motor protector accomplish this glorious and arduous task? Let's take a look at it.

1, the motor protector - - Introduction

Motor protector for the protection of the motor. When a series of abnormal phenomena such as short circuit, overload, overvoltage, leakage, bearing wear and phase absence occur in the motor, the connection can be automatically disconnected. Or when an error is detected, an alarm can be given immediately to remind people to deal with it in time. This type of protection not only exists on electric motors, but now almost all electronic products are automatically controlled and equipped with their own protective devices. The presence of the protector greatly reduces the manpower and time for error detection and is now widely used.

2, motor protector - classification

Motor protectors can be roughly divided into two types: bimetal type and thermistor plus electronic module type. Commonly used motor protectors include thermal relays, electronic motor protectors, and bimetal motor protectors (which can be further divided into thermal protectors and overload protectors). Intelligent motor protector, magnetic field temperature detection type click protector, etc. Next, we will give a detailed description of several of the motor protectors.

3, the principle of bimetal type motor protector

The bimetallic motor protector is mainly composed of two metal sheets. One of the metal sheets is an alloy having a large coefficient of thermal expansion, which is called an active layer, and the other metal sheet is an alloy having a small coefficient of thermal expansion, which is called a passive layer. When the temperature rises, the bimetal sheet is bent and deformed due to the difference in thermal expansion coefficient. When the temperature is lowered and then restored to the previous form, the bimetal motor protector uses this principle to achieve the closing and opening action of the switch at different temperatures.

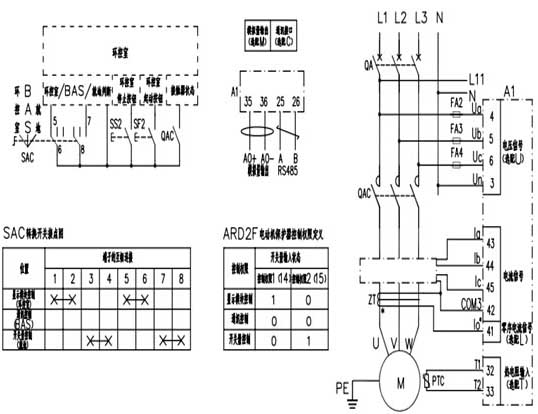

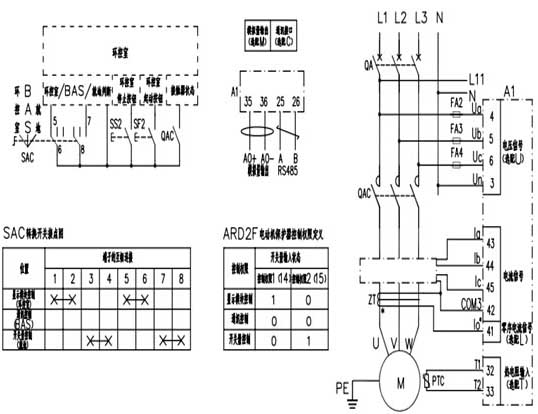

4, the principle of intelligent motor protector

The intelligent motor protector is generally suitable for the protection of the 380/660V low-voltage distribution network motor in industrial and mining enterprises. It is based on microcomputer technology, uses integrated circuits, and uses microprocessor as the core component, which not only realizes self-protection function. It can also be used for monitoring, measurement, communication, etc. It has the advantages of convenient operation, stable performance and simple maintenance. It is an upgraded product based on thermal relay and can be used directly as a replacement for thermal relays.

5, magnetic field temperature detection type motor protector principle

The magnetic field temperature detection type motor protector protects the motor by detecting the rotating magnetic field and temperature inside the motor. It can realize various protection functions such as phase loss, overload, wear detection and overheat protection. However, the premise operation is complicated, and it is necessary to insert a rotating magnetic field detecting coil and a temperature detecting device inside the motor.

1, the motor protector - - Introduction

Motor protector for the protection of the motor. When a series of abnormal phenomena such as short circuit, overload, overvoltage, leakage, bearing wear and phase absence occur in the motor, the connection can be automatically disconnected. Or when an error is detected, an alarm can be given immediately to remind people to deal with it in time. This type of protection not only exists on electric motors, but now almost all electronic products are automatically controlled and equipped with their own protective devices. The presence of the protector greatly reduces the manpower and time for error detection and is now widely used.

2, motor protector - classification

Motor protectors can be roughly divided into two types: bimetal type and thermistor plus electronic module type. Commonly used motor protectors include thermal relays, electronic motor protectors, and bimetal motor protectors (which can be further divided into thermal protectors and overload protectors). Intelligent motor protector, magnetic field temperature detection type click protector, etc. Next, we will give a detailed description of several of the motor protectors.

3, the principle of bimetal type motor protector

The bimetallic motor protector is mainly composed of two metal sheets. One of the metal sheets is an alloy having a large coefficient of thermal expansion, which is called an active layer, and the other metal sheet is an alloy having a small coefficient of thermal expansion, which is called a passive layer. When the temperature rises, the bimetal sheet is bent and deformed due to the difference in thermal expansion coefficient. When the temperature is lowered and then restored to the previous form, the bimetal motor protector uses this principle to achieve the closing and opening action of the switch at different temperatures.

4, the principle of intelligent motor protector

The intelligent motor protector is generally suitable for the protection of the 380/660V low-voltage distribution network motor in industrial and mining enterprises. It is based on microcomputer technology, uses integrated circuits, and uses microprocessor as the core component, which not only realizes self-protection function. It can also be used for monitoring, measurement, communication, etc. It has the advantages of convenient operation, stable performance and simple maintenance. It is an upgraded product based on thermal relay and can be used directly as a replacement for thermal relays.

5, magnetic field temperature detection type motor protector principle

The magnetic field temperature detection type motor protector protects the motor by detecting the rotating magnetic field and temperature inside the motor. It can realize various protection functions such as phase loss, overload, wear detection and overheat protection. However, the premise operation is complicated, and it is necessary to insert a rotating magnetic field detecting coil and a temperature detecting device inside the motor.