Thermostat / temperature control switch Test Equipment Analysis

Thermostat quality directly affects the safety of electrical equipment, performance, life,Is a very critical component.Currently on the market there are many thermostat / temperature control switch life test device manufacturer,Each has its advantages and disadvantages,Temperature control switch test equipment with rocker-type structure,Test process, the thermostat / temperature control switch installation deviation from the actual situation,Heating the thermal inertia of large, On the thermostat / temperature control switch a greater impact on life,Resulting in the test results are not accurate enough;Thermostat on / off adjustable range is small,Can not meet the product standard requirements;Thermostat test device maintenance complex,Always replace the heating body;Test device for narrow surface;Equipment operation is complex, expensive and so on.Our company based on years of temperature control / temperature control switch detection experience,A simple structure of the test device is designed,The device has been put into use,The practical use proves that the device is versatile,Close to the actual work,Test results are accurate,Easy to operate,low cost.

1, temperature control test equipment design standards

1.1 Electrical design of test equipment

The circuit of the thermostat / thermostat shall be tested at the manufacturer's rated load as the basic technical parameter

1.1.1 fast automatic (action) over-voltage test

Using 1.15 times the rated voltage and electrical load at that voltage.

1.1.2 fast automatic thermal protection (action) test

Using the rated voltage and the electrical load at that voltage.

1.2 Thermal conditions of the test equipment

When the thermostat / temperature control switch according to the method specified by the manufacturer installed,External parts should be exposed to room temperature.

1.3 mechanical conditions of the test equipment

1.3.1 During the slow test,The test equipment shall reliably drive the starter thermostat element,There is no significant hysteresis between the device and the thermostat element.

1.3.2 During the rapid test,The test equipment shall ensure that the test allows free operation of the thermostat element,So as not to interfere with the normal operation of the body.

2, temperature control test device introduced

2.1 Equipment parameters

Test voltage: 0-300VAC adjustable;

Electrical load: 1 ~ 60A adjustable;

Number of test setting range: 1000-99999;

Heating temperature adjustment range: -30 ℃ to 500 ℃;

Cooling air pressure: 0 ~ 1MPa;

Station: 5;

Comes with resistive load test stand,And can be an external load test bed; can be preset test number, cycle;With the test sample failure automatic detection and failure alarm function;And shows the number of trials.

2.2 Principles of thermostat equipment

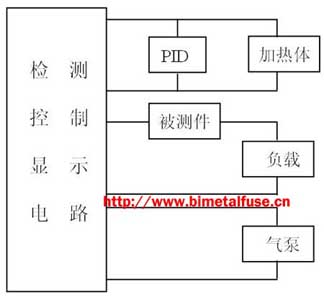

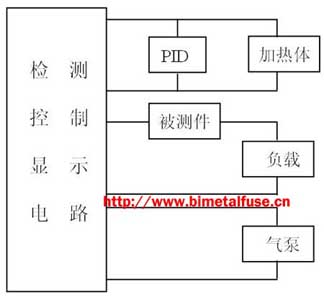

Thermostat device consists of four parts:A temperature rising portion, a gas flow cooling portion,A load section and a detection control display circuit,As shown in Figure 1.

Figure 1 thermostat test equipment components

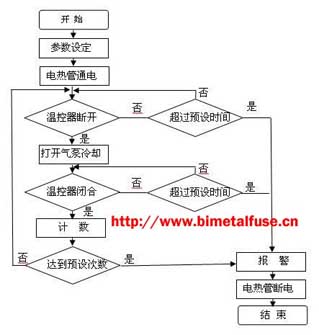

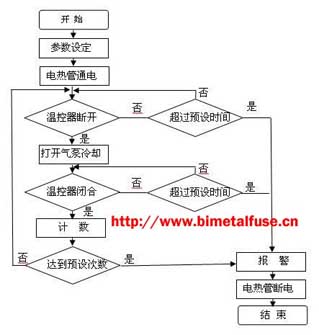

2.3 Thermostat / temperature control switch function flow

To normally closed thermostat / temperature control switch, for example,The temperature-sensitive parts of the heating block installed in the surface,Adjust the sample requirements of the electrical load,Set the heating block temperature,Fault alarm time,Life frequency and other parameters,Adjust the cooling gas pressure,So that the frequency and technical requirements to maintain consistency,Start the test,

Test flow shown in Figure 2.

Temperature controller test flow diagram

2.4 thermostat / temperature control switchgear main structure

What way to take the heating and cooling,Is the thermostat / temperature control switch life test device the most important part.

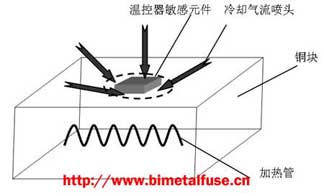

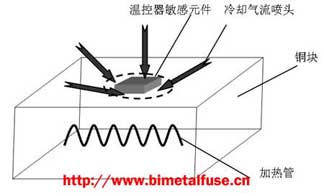

The device is heating up the use of copper block plus electric heating way to achieve,Electric tube placed inside the copper block,Heating using PID mode control.Heating tube power, heating copper block,The surface of the copper block is provided with a thermocouple,Real-time collection of temperature and the preset temperature of the copper block are compared,As shown in Figure 3.

The kind of heating method due to the thermal conductivity of copper is good,The surface temperature field uniformity is good,In order to achieve the heating temperature can be precisely adjusted,Heating speed,While thermal inertia is small,Effectively reduce the thermal overshoot on the test results;Copper block thicker larger,Heat capacity, cooling temperature rise quickly after;The heating device has a long life,The heating tube is located in the middle of the copper block,Cold and heat change is small,Not easily damaged.

Figure 3 thermostat test equipment heating / cooling schematic

Cooling is achieved in the following manner:

Ambient air through the air pump into a high-pressure airflow through the 1-4 nozzle applied to the copper plate,So that local rapid cooling copper plate,As shown in Figure 3,So that the temperature-sensitive parts of the temperature drop,thermostat/ temperature control switch is reset.This approach has three distinct advantages:

1, temperature control test equipment design standards

1.1 Electrical design of test equipment

The circuit of the thermostat / thermostat shall be tested at the manufacturer's rated load as the basic technical parameter

1.1.1 fast automatic (action) over-voltage test

Using 1.15 times the rated voltage and electrical load at that voltage.

1.1.2 fast automatic thermal protection (action) test

Using the rated voltage and the electrical load at that voltage.

1.2 Thermal conditions of the test equipment

When the thermostat / temperature control switch according to the method specified by the manufacturer installed,External parts should be exposed to room temperature.

1.3 mechanical conditions of the test equipment

1.3.1 During the slow test,The test equipment shall reliably drive the starter thermostat element,There is no significant hysteresis between the device and the thermostat element.

1.3.2 During the rapid test,The test equipment shall ensure that the test allows free operation of the thermostat element,So as not to interfere with the normal operation of the body.

2, temperature control test device introduced

2.1 Equipment parameters

Test voltage: 0-300VAC adjustable;

Electrical load: 1 ~ 60A adjustable;

Number of test setting range: 1000-99999;

Heating temperature adjustment range: -30 ℃ to 500 ℃;

Cooling air pressure: 0 ~ 1MPa;

Station: 5;

Comes with resistive load test stand,And can be an external load test bed; can be preset test number, cycle;With the test sample failure automatic detection and failure alarm function;And shows the number of trials.

2.2 Principles of thermostat equipment

Thermostat device consists of four parts:A temperature rising portion, a gas flow cooling portion,A load section and a detection control display circuit,As shown in Figure 1.

Figure 1 thermostat test equipment components

To normally closed thermostat / temperature control switch, for example,The temperature-sensitive parts of the heating block installed in the surface,Adjust the sample requirements of the electrical load,Set the heating block temperature,Fault alarm time,Life frequency and other parameters,Adjust the cooling gas pressure,So that the frequency and technical requirements to maintain consistency,Start the test,

Test flow shown in Figure 2.

Temperature controller test flow diagram

What way to take the heating and cooling,Is the thermostat / temperature control switch life test device the most important part.

The device is heating up the use of copper block plus electric heating way to achieve,Electric tube placed inside the copper block,Heating using PID mode control.Heating tube power, heating copper block,The surface of the copper block is provided with a thermocouple,Real-time collection of temperature and the preset temperature of the copper block are compared,As shown in Figure 3.

The kind of heating method due to the thermal conductivity of copper is good,The surface temperature field uniformity is good,In order to achieve the heating temperature can be precisely adjusted,Heating speed,While thermal inertia is small,Effectively reduce the thermal overshoot on the test results;Copper block thicker larger,Heat capacity, cooling temperature rise quickly after;The heating device has a long life,The heating tube is located in the middle of the copper block,Cold and heat change is small,Not easily damaged.

Figure 3 thermostat test equipment heating / cooling schematic

Ambient air through the air pump into a high-pressure airflow through the 1-4 nozzle applied to the copper plate,So that local rapid cooling copper plate,As shown in Figure 3,So that the temperature-sensitive parts of the temperature drop,thermostat/ temperature control switch is reset.This approach has three distinct advantages:

- The cooling rate varies with the pressure of the gas flow,Cooling air pressure in the range of 0-1MPa continuously adjustable,In order to achieve on-off time controllable,To meet the standard requirements or manufacturers claim their own test requirements;

- Cooling according to the measured temperature controller / temperature control switch of the size of the sensor area,Can be flexibly selected 1-4 nozzles applied thermostat / temperature control switch on the copper around the sensor block,To achieve temperature-sensitive components around the surface of the local cooling copper block,Without the entire thermostat / temperature control switch temperature down,On-off speed adjustable range is large;

-

The test piece is fixed on the copper plate,The most close to the thermostat / temperature control switch the actual work.

Thermostat test equipment suitable for:Bimetal thermostat,Liquid expansion thermostat,Mechanical thermostat,