Temperature control switch, temperature fuse used in motor overheating protection

1. Motor overheating protection hazards:

Motor overheating causes and hazards Motor overheating for many reasons,Such as running overload, type mismatch, cooling failure,Lack of monitoring and necessary maintenance lead to premature aging of insulation and so on.The motor in the operation will produce loss,These losses on the one hand reduces the motor efficiency,On the one hand the motor heat, Motor winding temperature increases,While the temperature is too high,Winding insulation will accelerate aging,Material insulation performance decreased dramatically,Greatly reducing the motor life,Even cause the motor on fire,Electric shock hazard.

2. Motor common fault protection component selection:

1>. Short-circuit protection or overcurrent protection (Overcurrent Protection):

When the motor equipment or distribution lines are overloaded or short-circuit fault,No delay automatically disconnect the circuit,The short-circuit protector disconnects the circuit in the form of fusing of metal or electromechanical.

Protection element used, for example:Fuses, circuit breakers

2>. Overload Protection:

For the motor current response,Provide overload current protection,Not necessarily short circuit protection,To a certain time limit automatically disconnect the circuit,The overload protector disconnects the circuit in the same way as a fuse blown or electromechanically.

Examples of protective elements used include: fuses, circuit breakers, thermal relays

3>. Overheating protection:

The motor is equipped with a built-in thermal protector,Can respond to the motor current and temperature,Or only respond to the motor temperature,When the allowable temperature is exceeded,Automatically disconnect the circuit to prevent motor overheating.

Examples of protective elements to be used are: Temperature fuse,Automatic reset temperature control switch,Manually reset the temperature control switch,Self-impedance protection

3. Motor installation temperature Fuse, temperature control switch method:

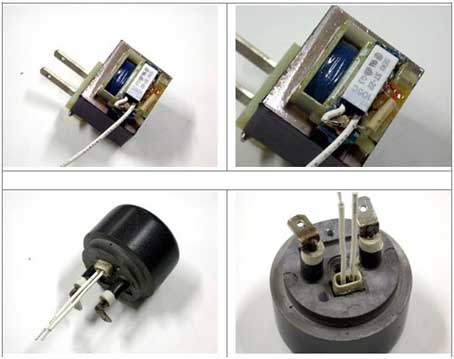

1>. Motor mounting temperature Fuse:

Temperature fuse in series with the motor in the input line,Or mounted on a carbon brush holder.When the motor work abnormal temperature rise,Temperature fuse temperature thermal cut,

Motor input is open,The motor stops working.Temperature fuse to play the role of over-temperature protection

Motor Mounting Temperature Fuse:

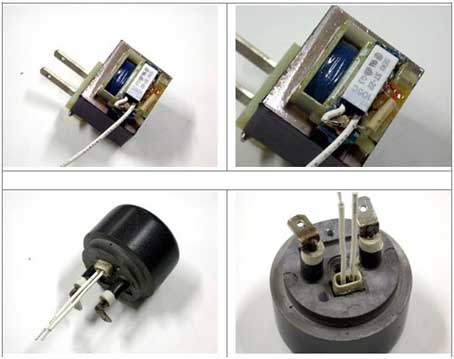

2>. Motor installation temperature control switch selection and installation:

1, the use of motor-mounted thermal protection,Conforms to CSA Standard C22.2 No.77 Motor with Inherent Overheating Protection.These motor overheat protector,Need to pay attention to use,The protector can not only respond to the motor current,Also need to have the appropriate rated operating voltage,The current value and the temperature predetermined protection value, And the thermal protector needs to be suitable for the motor.

2, the thermal protection device embedded in the motor (temperature control switch),According to the temperature of the motor windings to protect the protection effect is good;Installation: buried □ external □;With contact temperature-type installation,The temperature control switch should be close to the motor heating surface.However, when the motor capacity is large,Need to be used in conjunction with the current monitoring type,To avoid the motor stall temperature when the sharp rise,Due to the hysteresis of the temperature measuring element,Resulting in damage to the motor windings.

3, the working conditions for less demanding, simple operation control,Shutdown of the stand-alone production of little effect on the motor,Can choose ordinary type temperature control switch,As a result of ordinary type temperature control switch structure is simple,In the field installation wiring, the substitution is convenient, the operation is simple,With a high cost performance.

4, for poor working conditions,On the reliability of high demand,In particular to an electric motor for an automated production line,Should be used in high-end,Function than the whole intelligent protector.

Motor overheating causes and hazards Motor overheating for many reasons,Such as running overload, type mismatch, cooling failure,Lack of monitoring and necessary maintenance lead to premature aging of insulation and so on.The motor in the operation will produce loss,These losses on the one hand reduces the motor efficiency,On the one hand the motor heat, Motor winding temperature increases,While the temperature is too high,Winding insulation will accelerate aging,Material insulation performance decreased dramatically,Greatly reducing the motor life,Even cause the motor on fire,Electric shock hazard.

2. Motor common fault protection component selection:

1>. Short-circuit protection or overcurrent protection (Overcurrent Protection):

When the motor equipment or distribution lines are overloaded or short-circuit fault,No delay automatically disconnect the circuit,The short-circuit protector disconnects the circuit in the form of fusing of metal or electromechanical.

Protection element used, for example:Fuses, circuit breakers

2>. Overload Protection:

For the motor current response,Provide overload current protection,Not necessarily short circuit protection,To a certain time limit automatically disconnect the circuit,The overload protector disconnects the circuit in the same way as a fuse blown or electromechanically.

Examples of protective elements used include: fuses, circuit breakers, thermal relays

3>. Overheating protection:

The motor is equipped with a built-in thermal protector,Can respond to the motor current and temperature,Or only respond to the motor temperature,When the allowable temperature is exceeded,Automatically disconnect the circuit to prevent motor overheating.

Examples of protective elements to be used are: Temperature fuse,Automatic reset temperature control switch,Manually reset the temperature control switch,Self-impedance protection

3. Motor installation temperature Fuse, temperature control switch method:

1>. Motor mounting temperature Fuse:

Temperature fuse in series with the motor in the input line,Or mounted on a carbon brush holder.When the motor work abnormal temperature rise,Temperature fuse temperature thermal cut,

Motor input is open,The motor stops working.Temperature fuse to play the role of over-temperature protection

Motor Mounting Temperature Fuse:

2>. Motor installation temperature control switch selection and installation:

1, the use of motor-mounted thermal protection,Conforms to CSA Standard C22.2 No.77 Motor with Inherent Overheating Protection.These motor overheat protector,Need to pay attention to use,The protector can not only respond to the motor current,Also need to have the appropriate rated operating voltage,The current value and the temperature predetermined protection value, And the thermal protector needs to be suitable for the motor.

2, the thermal protection device embedded in the motor (temperature control switch),According to the temperature of the motor windings to protect the protection effect is good;Installation: buried □ external □;With contact temperature-type installation,The temperature control switch should be close to the motor heating surface.However, when the motor capacity is large,Need to be used in conjunction with the current monitoring type,To avoid the motor stall temperature when the sharp rise,Due to the hysteresis of the temperature measuring element,Resulting in damage to the motor windings.

3, the working conditions for less demanding, simple operation control,Shutdown of the stand-alone production of little effect on the motor,Can choose ordinary type temperature control switch,As a result of ordinary type temperature control switch structure is simple,In the field installation wiring, the substitution is convenient, the operation is simple,With a high cost performance.

4, for poor working conditions,On the reliability of high demand,In particular to an electric motor for an automated production line,Should be used in high-end,Function than the whole intelligent protector.