Motor Thermal Protector Supplier

Motor Thermal Protector

Motor is a very wide range of mechanical and electrical equipment, work in all walks of life often used. If you do not take protective measures on the motor, it may cause a safety accident, motor-driven electrical hazards in use may present a risk of electric shock and a fire hazard.

What Is The Motor Thermal Protector

Motor thermal protector is a bimetallic superheat protector, is the thermal protection device for the normal operation of the motor. In Ya Xun, to provide a full range of motor thermal protection, such as: DC, single-phase, three-phase, low-voltage motor, high-voltage motor.

There are many reasons for motor overheating, such as running overload, selection is not appropriate, cooling failure, lack of monitoring and necessary maintenance leading to premature aging of insulation.

The motor in the run-time will produce losses, these losses on the one hand to reduce the efficiency of the motor, on the other hand the loss turns into a motor heating, so that the motor winding temperature increases.

The life of the winding insulation material is related to its operating temperature. The temperature is too high, the insulation material will accelerate aging, so that a significant reduction in insulation performance, significantly shorten the life of the motor, even the risk of fire and electric shock hazard. Therefore, the purpose of motor overheating protection, mainly in the design, manufacture, installation and use of motor protection measures, when the motor is operating under certain load and heat dissipation conditions, the temperature of the winding does not exceed the allowable value of the standard.

Example - Three-phase Motor Overheat Orotection (6AP, 3MP, 5AP, 2MP, 17AM, 8AM)

Three - phase motor thermal protection. Its advantage is that, it has a dual function of current overload protection and thermal protection.

When the motor winding coil current overload (large) exceeds the motor current rating multiple, thermal protection device can automatically disconnect the power circuit, thus protecting the motor safety.

17 AM, 6AP has a motor overload, lack of phase, stall and other circuits play a protective role. The method can be applied to any connection form three-phase motor, submersible pumps, etc., automatically disconnect the power circuitry within 4 to 10 seconds.

The thermal protector can be installed in the motor, can also be installed outside the motor, can also be installed on all machine control panels. Even can be installed on the wall of the power distribution board. It can replace the thermal relay and AC contactor used in conjunction with the motor protection device.

Yaxing thermal protector can be used in high pollution environment (This is because the AC contactor is not fully enclosed and its silver contacts are particularly susceptible to damage in highly polluted environments, so AC contactors can not be used in highly polluted environments). With energy saving, action sensitive, reliable, affordable and so on. Easy to use and install, there are obvious economic and social benefits. Now the world, there is no thermal protection device can be installed in the device control board, and can be wall-mounted distribution board. This is Ya Xun's patented product thermal protector advantage.

This thermal protection wide range of applications. Support power: 0.55KW - 75KW (5A - 150A)

Power supply voltage: 220V / 380V

Temperature range: 40 degrees - 150 degrees

Features

1. Wide range of applications;

2. Structural design precision;

3. Can also sense the temperature and current;

4. action fast and accurate;

5. Certification is complete: UL certification, CUL certification, VDE certification, RoHS certification;

6. Function: single-hop characteristics, the temperature reaches the automatic disconnect circuit;

7. Accuracy of action temperature ± 2 ℃ ± 3 ℃ ± 5 ℃;

8. can be repeated action ≥ 10000 times;

9. Small size

10. Bimetallic sheet with fast trip characteristics (snap act 10n)

11. With the induction current and temperature and the performance of the action

12. Support a wide range of power: 0.55KW - 75KW (5A - 150A)

Product Structure And Size

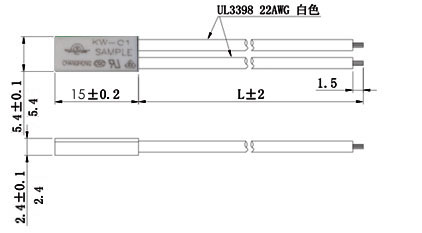

1> Minimum motor thermal protector (TB02)

Temperature head size: 1, PBT shell 15 * 5.4 * 2.4mm; 2, metal shell: 11.5 * 5 * 2.4mm

Electrical Specifications:

● 2.5A / 250V AC

● 5A / 120 V AC

● 10A / 12V AC

● 5A / 24V AC

Operating temperature: 30 ~ 155 ℃

Accuracy: ± 5, ± 3

Internal resistance: less than 25 mΩ

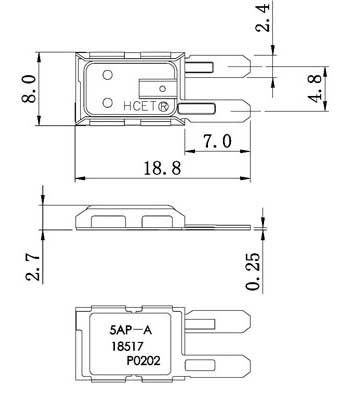

2> current, temperature double protection motor protection (product models are: 6AP, 3MP, 5AP, 2MP, 18AM)

Electrical specifications:

● 30 amps/15 volts DC

● 15 amps/30 volts DC

● 25 amps/250 volts AC

● 35 amps/125 volts AC

Technical Parameters:

● Operating temperature range: 50 ℃ - 180 ℃, according to customer requirements within the scope of any temperature.

● Temperature tolerance: ± 5 ℃, ± 3 ℃

● Select to control the overload current trip range: 1A-35A

● trip time: 3S-8S (special can be customized)

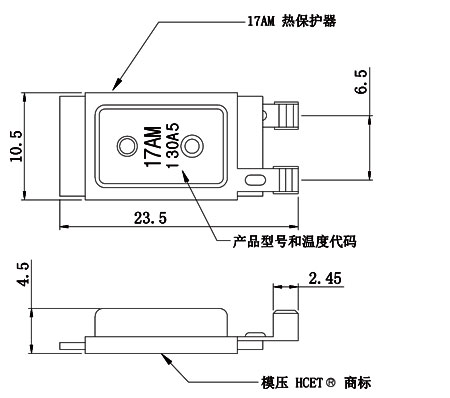

3> 17AM motor thermal protector

17AM series protector is a kind of over-temperature, over-current protection, its small size, large contact capacity, jump action quickly, mainly used in motors, lamps and small appliances overtemperature overcurrent protection.

Electrical Specifications:

20 amps/16 volts DC

10 amps/250 volts DC

20 amps/125 volts DC

Technical Parameters:

Use temperature range: 50 ℃ -180 ℃, according to customer requirements within the scope of any temperature

Temperature tolerance: ± 3 ℃, ± 5 ℃, two kinds of tolerance for customers to choose, usually ± 5 ℃

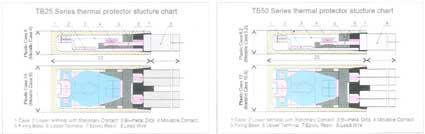

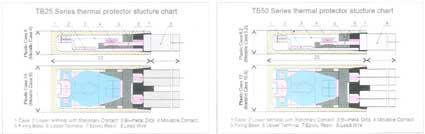

4> High Power Motor Thermal Protector (TB25, TB50)

TB25 Electrical Specifications:

AC250V / 25A 10,000Cycles

TB25-BB5D Molded Case Size: 22mm × 10mm × 5.0mm

TB25-BB1D iron shell size: 22mm × 9.0mm × 4.0mm

TB50 Electrical Specifications:

AC250V / 50A 10,000Cycles

TB50-BB5D Molded Case Size: 25mm × 10.6mm × 5.2mm

TB50-BB1D iron shell size: 25mm × 12.0mm × 6.2mm

● Operating temperature range: 30 ℃ - 180 ℃, according to customer requirements within the scope of any temperature.

● Temperature tolerance: ± 3 ℃, ± 5 ℃, ± 8 ℃

● Select to control the overload current trip range: 1A-50A

● trip time: 3S-8S (special can be customized)

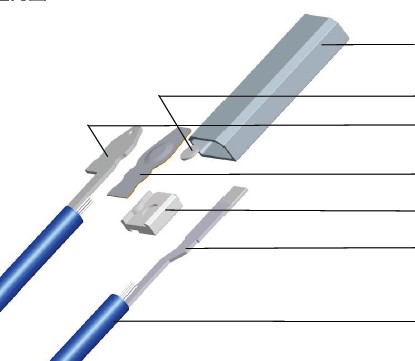

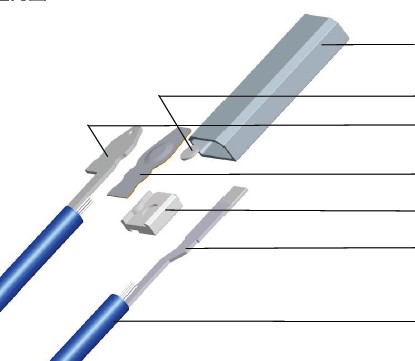

Composition Parts And Assembly Drawings

Housing: PBT

Movable contact :silver and copper alloy

Movable contact: SPCC

Temperature film: Bimetallic

Fixed seat: PBT

Static contact: Silver and copper alloy

Wire: Radiation line

Selection Criteria for Motor Thermal Protectors

1, the motor parameters: first understand the motor specifications, functional characteristics, protection type, rated voltage, rated current, rated power, power frequency, insulation level. These parameters can basically give the user the correct choice of protection provided a reference.

2, environmental conditions: mainly refers to room temperature, high temperature, alpine, corrosion, vibration, sand, altitude, electromagnetic pollution.

3, motor use: Such as fans, pumps, air compressors, lathes, pumping units, and other different load mechanical characteristics.

4, control mode: control mode has manual, automatic, local control, remote control, stand-alone operation, centralized control of production lines and so on.

5. Other areas: customer care management of on-site production, abnormal shutdown of the severity of the impact on production and so on.

There are many factors related to the choice of thermal protection, such as installation location, power supply, power distribution system; Also consider shopping for new motor configuration protection, motor protection or upgrade, or to improve the protection of accident and other motor; But also to consider the difficulty of motor protection and change the impact of the degree of production; According to the actual working conditions of the scene to consider the protection of the selection and adjustment.

When you choose a thermal protection for the motor, please contact our professional team, they will give the most practical, the most favorable price of the product, for your products to quickly enter the market conditions.

Motor is a very wide range of mechanical and electrical equipment, work in all walks of life often used. If you do not take protective measures on the motor, it may cause a safety accident, motor-driven electrical hazards in use may present a risk of electric shock and a fire hazard.

What Is The Motor Thermal Protector

Motor thermal protector is a bimetallic superheat protector, is the thermal protection device for the normal operation of the motor. In Ya Xun, to provide a full range of motor thermal protection, such as: DC, single-phase, three-phase, low-voltage motor, high-voltage motor.

There are many reasons for motor overheating, such as running overload, selection is not appropriate, cooling failure, lack of monitoring and necessary maintenance leading to premature aging of insulation.

The motor in the run-time will produce losses, these losses on the one hand to reduce the efficiency of the motor, on the other hand the loss turns into a motor heating, so that the motor winding temperature increases.

The life of the winding insulation material is related to its operating temperature. The temperature is too high, the insulation material will accelerate aging, so that a significant reduction in insulation performance, significantly shorten the life of the motor, even the risk of fire and electric shock hazard. Therefore, the purpose of motor overheating protection, mainly in the design, manufacture, installation and use of motor protection measures, when the motor is operating under certain load and heat dissipation conditions, the temperature of the winding does not exceed the allowable value of the standard.

Example - Three-phase Motor Overheat Orotection (6AP, 3MP, 5AP, 2MP, 17AM, 8AM)

Three - phase motor thermal protection. Its advantage is that, it has a dual function of current overload protection and thermal protection.

When the motor winding coil current overload (large) exceeds the motor current rating multiple, thermal protection device can automatically disconnect the power circuit, thus protecting the motor safety.

17 AM, 6AP has a motor overload, lack of phase, stall and other circuits play a protective role. The method can be applied to any connection form three-phase motor, submersible pumps, etc., automatically disconnect the power circuitry within 4 to 10 seconds.

The thermal protector can be installed in the motor, can also be installed outside the motor, can also be installed on all machine control panels. Even can be installed on the wall of the power distribution board. It can replace the thermal relay and AC contactor used in conjunction with the motor protection device.

Yaxing thermal protector can be used in high pollution environment (This is because the AC contactor is not fully enclosed and its silver contacts are particularly susceptible to damage in highly polluted environments, so AC contactors can not be used in highly polluted environments). With energy saving, action sensitive, reliable, affordable and so on. Easy to use and install, there are obvious economic and social benefits. Now the world, there is no thermal protection device can be installed in the device control board, and can be wall-mounted distribution board. This is Ya Xun's patented product thermal protector advantage.

This thermal protection wide range of applications. Support power: 0.55KW - 75KW (5A - 150A)

Power supply voltage: 220V / 380V

Temperature range: 40 degrees - 150 degrees

Features

1. Wide range of applications;

2. Structural design precision;

3. Can also sense the temperature and current;

4. action fast and accurate;

5. Certification is complete: UL certification, CUL certification, VDE certification, RoHS certification;

6. Function: single-hop characteristics, the temperature reaches the automatic disconnect circuit;

7. Accuracy of action temperature ± 2 ℃ ± 3 ℃ ± 5 ℃;

8. can be repeated action ≥ 10000 times;

9. Small size

10. Bimetallic sheet with fast trip characteristics (snap act 10n)

11. With the induction current and temperature and the performance of the action

12. Support a wide range of power: 0.55KW - 75KW (5A - 150A)

Product Structure And Size

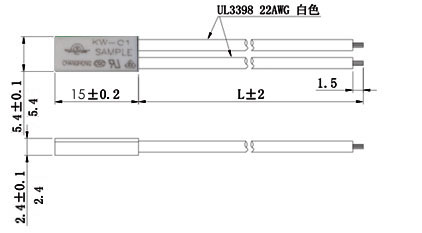

1> Minimum motor thermal protector (TB02)

Temperature head size: 1, PBT shell 15 * 5.4 * 2.4mm; 2, metal shell: 11.5 * 5 * 2.4mm

Electrical Specifications:

● 2.5A / 250V AC

● 5A / 120 V AC

● 10A / 12V AC

● 5A / 24V AC

Operating temperature: 30 ~ 155 ℃

Accuracy: ± 5, ± 3

Internal resistance: less than 25 mΩ

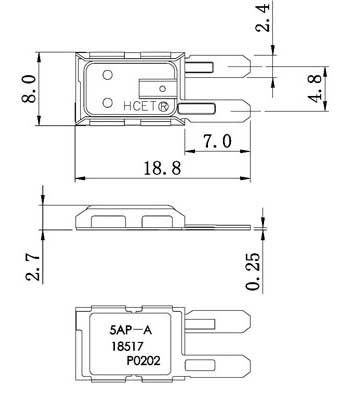

2> current, temperature double protection motor protection (product models are: 6AP, 3MP, 5AP, 2MP, 18AM)

Electrical specifications:

● 30 amps/15 volts DC

● 15 amps/30 volts DC

● 25 amps/250 volts AC

● 35 amps/125 volts AC

Technical Parameters:

● Operating temperature range: 50 ℃ - 180 ℃, according to customer requirements within the scope of any temperature.

● Temperature tolerance: ± 5 ℃, ± 3 ℃

● Select to control the overload current trip range: 1A-35A

● trip time: 3S-8S (special can be customized)

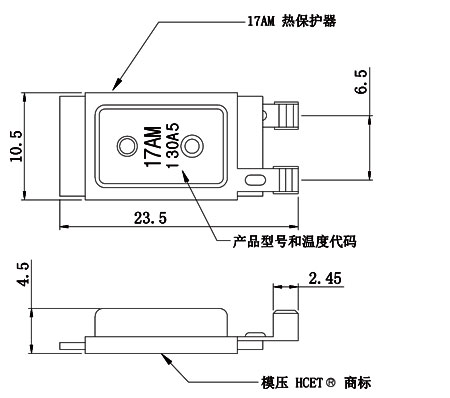

3> 17AM motor thermal protector

17AM series protector is a kind of over-temperature, over-current protection, its small size, large contact capacity, jump action quickly, mainly used in motors, lamps and small appliances overtemperature overcurrent protection.

Electrical Specifications:

20 amps/16 volts DC

10 amps/250 volts DC

20 amps/125 volts DC

Technical Parameters:

Use temperature range: 50 ℃ -180 ℃, according to customer requirements within the scope of any temperature

Temperature tolerance: ± 3 ℃, ± 5 ℃, two kinds of tolerance for customers to choose, usually ± 5 ℃

4> High Power Motor Thermal Protector (TB25, TB50)

TB25 Electrical Specifications:

AC250V / 25A 10,000Cycles

TB25-BB5D Molded Case Size: 22mm × 10mm × 5.0mm

TB25-BB1D iron shell size: 22mm × 9.0mm × 4.0mm

TB50 Electrical Specifications:

AC250V / 50A 10,000Cycles

TB50-BB5D Molded Case Size: 25mm × 10.6mm × 5.2mm

TB50-BB1D iron shell size: 25mm × 12.0mm × 6.2mm

● Operating temperature range: 30 ℃ - 180 ℃, according to customer requirements within the scope of any temperature.

● Temperature tolerance: ± 3 ℃, ± 5 ℃, ± 8 ℃

● Select to control the overload current trip range: 1A-50A

● trip time: 3S-8S (special can be customized)

Composition Parts And Assembly Drawings

Housing: PBT

Movable contact :silver and copper alloy

Movable contact: SPCC

Temperature film: Bimetallic

Fixed seat: PBT

Static contact: Silver and copper alloy

Wire: Radiation line

Selection Criteria for Motor Thermal Protectors

1, the motor parameters: first understand the motor specifications, functional characteristics, protection type, rated voltage, rated current, rated power, power frequency, insulation level. These parameters can basically give the user the correct choice of protection provided a reference.

2, environmental conditions: mainly refers to room temperature, high temperature, alpine, corrosion, vibration, sand, altitude, electromagnetic pollution.

3, motor use: Such as fans, pumps, air compressors, lathes, pumping units, and other different load mechanical characteristics.

4, control mode: control mode has manual, automatic, local control, remote control, stand-alone operation, centralized control of production lines and so on.

5. Other areas: customer care management of on-site production, abnormal shutdown of the severity of the impact on production and so on.

There are many factors related to the choice of thermal protection, such as installation location, power supply, power distribution system; Also consider shopping for new motor configuration protection, motor protection or upgrade, or to improve the protection of accident and other motor; But also to consider the difficulty of motor protection and change the impact of the degree of production; According to the actual working conditions of the scene to consider the protection of the selection and adjustment.

When you choose a thermal protection for the motor, please contact our professional team, they will give the most practical, the most favorable price of the product, for your products to quickly enter the market conditions.