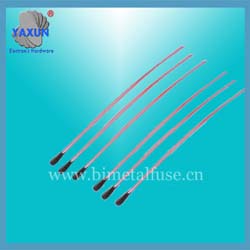

Small black Epoxy Radial resin ntc thermistor Probes

- PRODUCT DETAIL

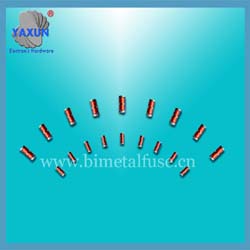

This epoxy coating method is called dip coating. After the epoxy glue is prepared, the thermistor is placed in the epoxy resin, so the epoxy resin can be stained on the surface of the NTC element. The thickness of the package can be controlled by multiple dip coatings.

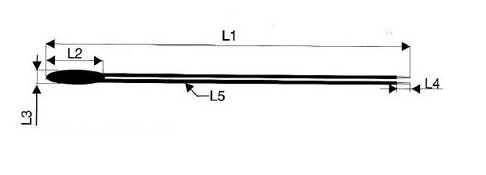

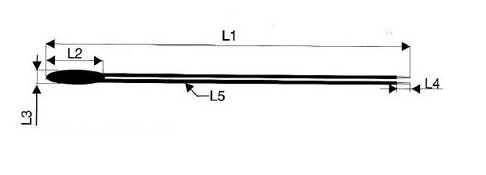

A: Size chart

Note: The size and wire color according to customer requirements!

II: Product Features:

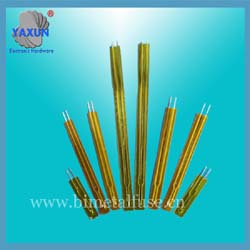

1: MF52 series of products for the lead with an epoxy coating type

2: Wide range of resistance: 0.1KΩ ~ 500KΩ

3: Resistance and B value of high accuracy

4: moisture proof, good insulation, high reliability, small time constant

5: small, reflecting the speed

6: is stable for a long time, consistency

7: Operating temperature range: -40 ~ 125 ℃

3: Product Applications:

Air-conditioning equipment, heating equipment, medical equipment, temperature control instrumentation, electronic gifts, electronic hygrometer, car thermometer, electronic calendar, rechargeable battery pack and charger, laptop batteries.

Four: Model Description

MF 52 103 F 3950

① ② ③ ④ ⑤

①MF ¬-- negative temperature coefficient (NTC) thermistor Code.

②52-- epoxy encapsulated NTC thermistor temperature sensor.

③103 - thermistor nominal resistance, indicating that the nominal resistance of the resistance: 10 × 103 (Ω).

Error ④F-- resistance value (accuracy) is: F = ± 1%, G = ± 2%, H = ± 3%, J = ± 5%

⑤3950-- thermal resistance index (material factor) B is: 395 × 10 (K)

Five: MF52 Series Model Specification

Note: according to customer requirements, provide different resistance, B value precision, customization.

NTC thermistor measurements must note the following:

• can not be measured in the air, the larger the difference in air temperature measurement inaccurate, resulting accuracy deviation.

• After using the high-precision measurements of the bath, measured after NTC into the bath, the bath temperature must be stable before measurement.

• Measure the voltage as low as possible in order to reduce measurement errors due to self-heating NTC.

• High temperature measurement, required temperature bath thermometer correction, check

A: Size chart

Note: The size and wire color according to customer requirements!

II: Product Features:

1: MF52 series of products for the lead with an epoxy coating type

2: Wide range of resistance: 0.1KΩ ~ 500KΩ

3: Resistance and B value of high accuracy

4: moisture proof, good insulation, high reliability, small time constant

5: small, reflecting the speed

6: is stable for a long time, consistency

7: Operating temperature range: -40 ~ 125 ℃

3: Product Applications:

Air-conditioning equipment, heating equipment, medical equipment, temperature control instrumentation, electronic gifts, electronic hygrometer, car thermometer, electronic calendar, rechargeable battery pack and charger, laptop batteries.

Four: Model Description

MF 52 103 F 3950

① ② ③ ④ ⑤

①MF ¬-- negative temperature coefficient (NTC) thermistor Code.

②52-- epoxy encapsulated NTC thermistor temperature sensor.

③103 - thermistor nominal resistance, indicating that the nominal resistance of the resistance: 10 × 103 (Ω).

Error ④F-- resistance value (accuracy) is: F = ± 1%, G = ± 2%, H = ± 3%, J = ± 5%

⑤3950-- thermal resistance index (material factor) B is: 395 × 10 (K)

Five: MF52 Series Model Specification

Note: according to customer requirements, provide different resistance, B value precision, customization.

NTC thermistor measurements must note the following:

• can not be measured in the air, the larger the difference in air temperature measurement inaccurate, resulting accuracy deviation.

• After using the high-precision measurements of the bath, measured after NTC into the bath, the bath temperature must be stable before measurement.

• Measure the voltage as low as possible in order to reduce measurement errors due to self-heating NTC.

• High temperature measurement, required temperature bath thermometer correction, check

| Model | Rated resistance(R25) | B Value |

work Temperature |

Dissipation factor(mW/℃) |

Thermal time constant(S) |

|

|

Resistance (KΩ) |

Tolerance (± %) |

Nominal value (K) |

||||

| MF52-102-3950 | 1 |

±1% ±2% ±3% ±5% |

3950 |

-40℃ ~ +200℃ |

≥2.0 Still air |

≤15 Still air |

| MF52-152-3950 | 1.5 | 3950 | ||||

| MF52-202-3435 | 2 | 3435 | ||||

| MF52-2.252-3950 | 2.252 | 3950 | ||||

| MF52-472-3950 | 4.7 | 3950 | ||||

| MF52-502-3470 | 5 | 3470 | ||||

| MF52-502-3950 | 5 | 3950 | ||||

| MF52-682-3950 | 6.8 | 3950 | ||||

| MF52-103-3435 | 10 | 3435 | ||||

| MF52-103-3470 | 10 | 3470 | ||||

| MF52-103-3600 | 10 | 3600 | ||||

| MF52-103-3950 | 10 | 3950 | ||||

| MF52-103-3977 | 10 | 3977 | ||||

| MF52-103-4100 | 10 | 4100 | ||||

| MF52-153-3950 | 15 | 3950 | ||||

| MF52-203-3950 | 20 | 3950 | ||||

| MF52-233-3950 | 23 | 3950 | ||||

| MF52-303-3950 | 30 | 3950 | ||||

| MF52-333-3950 | 33 | 3950 | ||||

| MF52-40.27-3950 | 40.27 | 3950 | ||||

| MF52-473-3950 | 47 | 3950 | ||||

| MF52-503-3950 | 50 | 3950 | ||||

| MF52-503-3990 | 50 | 3990 | ||||

| MF52-503-4050 | 50 | 4050 | ||||

| MF52-104-3950 | 100 | 3950 | ||||

| MF52-104-3990 | 100 | 3990 | ||||

| MF52-104-4200 | 100 | 4050 | ||||

| MF52-204-3950 | 200 | 3950 | ||||

| MF52-204-4260 | 200 | 4260 | ||||