Interruptor de Termostato Bimetálico

Modelos convencionales de interruptores termostáticos bimetálicos: Voltaje: 12 voltios/240V/120V. Corriente: 0,5 mA, 1 A, 2 A, 10 A, 16 A, 25 A, 40 A. (NO, NC, reinicio automático, reinicio manual) KSD301, KSD302, KSD9700, TB02, para ventilador, automóvil, refrigerador, calentador, hervidor eléctrico, calentador de agua.

El interruptor de control de temperatura bimetálico se refiere a la deformación física que ocurre dentro del interruptor según el cambio de temperatura del ambiente de trabajo, produciendo así algunos efectos térmicos especiales. Una serie de componentes de control automático que producen acciones de encendido o apagado. También llamado interruptor térmico, interruptor de temperatura, interruptor de corte térmico o, para abreviar, termostato. O la temperatura se transmite al controlador de temperatura a través del protector de temperatura, y el controlador de temperatura emite un comando de interruptor para controlar el funcionamiento del equipo para lograr la temperatura ideal y el efecto de ahorro de energía.

Los termostatos tienen una amplia gama de aplicaciones. Se utilizan diferentes tipos de termostatos en muchos productos como electrodomésticos, motores, refrigeración o calefacción.

Bimetallic thermal cut-out switch

How bimetallic thermal cut-out switches work

Its working principle is to automatically sample and monitor the ambient temperature in real time through a temperature sensor. When the ambient temperature is higher than the control set value, the control circuit starts and the control hysteresis can be set. If the temperature is still rising, when it reaches the set over-limit alarm temperature point, the over-limit alarm function will be activated. When the controlled temperature cannot be effectively controlled, in order to prevent equipment damage, the trip function can be used to stop the equipment from continuing to run. Mainly used in various high and low voltage switch cabinets, dry-type transformers, box-type substations and other related temperature use areas used in the power sector.

Bimetal thermal cut-off switch wiring method

Look carefully at the three pins on the thermostat. They are replaced by English letters and numbers, respectively: H (6), L (3), C (4).

H (6) is connected to the brown wire, which is the live wire of the power supply;

L (3) is connected to the gray wire, which is the live wire of the lamp;

C(4) is connected to the white wire, which is the live wire of the compressor.

Control method of bimetallic thermal cut-off switch

Control methods are generally divided into two types: one is controlled by the temperature change of the object to be cooled, and a vapor pressure temperature controller is often used. The other is controlled by the temperature difference change of the object to be cooled, and electronic temperature controllers are often used.

It adopts fuzzy control technology such as PID control, P (Proportional) proportion + I (Integral) integral + D (Differential) differential control.

Bimetal jump thermostat

The bimetallic jump thermostat uses a fixed-temperature bimetal as a heat-sensitive reaction component. When the temperature of the main part of the product increases, the heat generated is transferred to the bimetal disc. It acts quickly when the operating temperature setting is reached, and the contacts are opened or closed through the action of the mechanism. When the temperature drops to the reset temperature setting, the bimetal quickly returns to its original state, causing the contacts to close or open to connect or disconnect the circuit, thereby controlling the circuit.

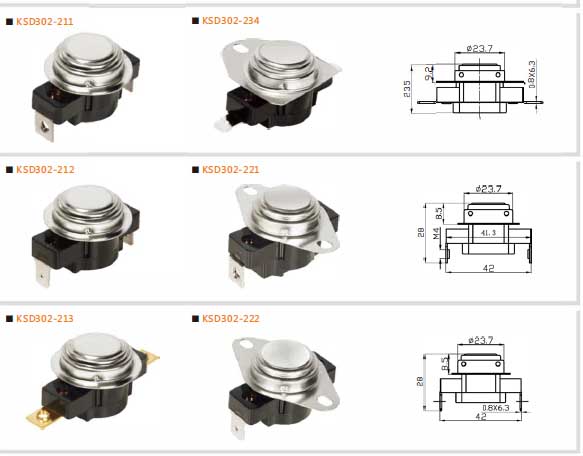

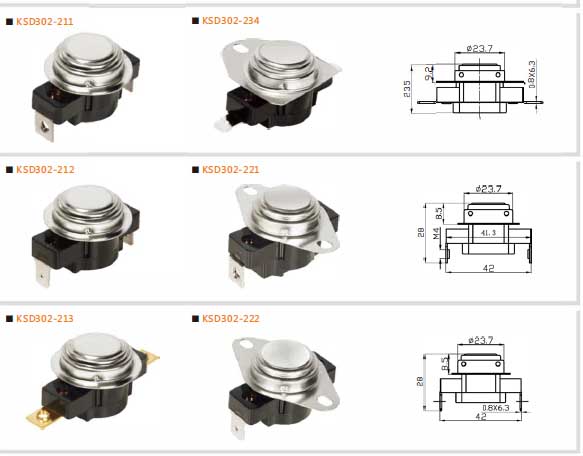

The models of various jump-type thermostats are collectively called KSD, and the common ones are KSD301, KSD302, etc. This thermostat is a new product of bimetallic thermostat. Mainly used as overheating protection for various electric heating products, it is usually used in series with a thermal fuse, and the snap-type thermostat is used as the first-level protection. The thermal fuse acts as a secondary protection when the sudden thermostat fails or fails and causes the electric heating element to overheat, effectively preventing the electric heating element from burning out and the resulting fire accident.

El interruptor de control de temperatura bimetálico se refiere a la deformación física que ocurre dentro del interruptor según el cambio de temperatura del ambiente de trabajo, produciendo así algunos efectos térmicos especiales. Una serie de componentes de control automático que producen acciones de encendido o apagado. También llamado interruptor térmico, interruptor de temperatura, interruptor de corte térmico o, para abreviar, termostato. O la temperatura se transmite al controlador de temperatura a través del protector de temperatura, y el controlador de temperatura emite un comando de interruptor para controlar el funcionamiento del equipo para lograr la temperatura ideal y el efecto de ahorro de energía.

Los termostatos tienen una amplia gama de aplicaciones. Se utilizan diferentes tipos de termostatos en muchos productos como electrodomésticos, motores, refrigeración o calefacción.

Bimetallic thermal cut-out switch

How bimetallic thermal cut-out switches work

Its working principle is to automatically sample and monitor the ambient temperature in real time through a temperature sensor. When the ambient temperature is higher than the control set value, the control circuit starts and the control hysteresis can be set. If the temperature is still rising, when it reaches the set over-limit alarm temperature point, the over-limit alarm function will be activated. When the controlled temperature cannot be effectively controlled, in order to prevent equipment damage, the trip function can be used to stop the equipment from continuing to run. Mainly used in various high and low voltage switch cabinets, dry-type transformers, box-type substations and other related temperature use areas used in the power sector.

Bimetal thermal cut-off switch wiring method

Look carefully at the three pins on the thermostat. They are replaced by English letters and numbers, respectively: H (6), L (3), C (4).

H (6) is connected to the brown wire, which is the live wire of the power supply;

L (3) is connected to the gray wire, which is the live wire of the lamp;

C(4) is connected to the white wire, which is the live wire of the compressor.

Control method of bimetallic thermal cut-off switch

Control methods are generally divided into two types: one is controlled by the temperature change of the object to be cooled, and a vapor pressure temperature controller is often used. The other is controlled by the temperature difference change of the object to be cooled, and electronic temperature controllers are often used.

It adopts fuzzy control technology such as PID control, P (Proportional) proportion + I (Integral) integral + D (Differential) differential control.

Bimetal jump thermostat

The bimetallic jump thermostat uses a fixed-temperature bimetal as a heat-sensitive reaction component. When the temperature of the main part of the product increases, the heat generated is transferred to the bimetal disc. It acts quickly when the operating temperature setting is reached, and the contacts are opened or closed through the action of the mechanism. When the temperature drops to the reset temperature setting, the bimetal quickly returns to its original state, causing the contacts to close or open to connect or disconnect the circuit, thereby controlling the circuit.

The models of various jump-type thermostats are collectively called KSD, and the common ones are KSD301, KSD302, etc. This thermostat is a new product of bimetallic thermostat. Mainly used as overheating protection for various electric heating products, it is usually used in series with a thermal fuse, and the snap-type thermostat is used as the first-level protection. The thermal fuse acts as a secondary protection when the sudden thermostat fails or fails and causes the electric heating element to overheat, effectively preventing the electric heating element from burning out and the resulting fire accident.