Thermostat life test method

1, the thermostat product introductionKSD301 temperature controller is widely used in a variety of home appliances, such as refrigerators, drinking fountains, water heaters, coffee pots,Induction Cooker, microwave ovens, rice cookers, air conditioners and so on.KSD301 temperature controller directly affects the quality of the safety of home appliances,Performance and longevity, is very critical thermal protection components.KSD301 temperature controller in a number of technical indicators,Life is a measure of KSD301 temperature controller products, one of the most important technical indicators.Electrical life standards,Thermostat life of at least 10,000 times,Some household appliances,Such as the refrigerator control motor - compressor KSD301 thermostat,Life requirements of at least 100,000 times.KSD301 thermostat corresponding to the standard GB14536.10-2008 / IEC60730-2-9: 2004,Life test of the thermostat made detailed provisions.

2, temperature control test device introduced

2.1 Equipment parametersTest voltage: 0-300VAC adjustable; Electrical load: 1 ~ 30A adjustable; Number of test setting range: 1000-99999;

Temperature adjustment range: -20 ℃ to 500 ℃;

Cooling air pressure: 0 ~ 1MPa;

Station: 5; own resistance load Taiwan, And an external load Taiwan; Can be preset number of test cycles; With the test sample failure automatic detection and failure alarm function; And shows the number of trials.

3, thermostat testing standards

3.1 Electrical tests

KSD301 thermostat of each circuit, It shall be specified by the manufacturer's rated load test as the basic technical parameters

3.1.1 fast automatic over-voltage, over-current test

1.15 times the rated voltage and the electrical load at that voltage.

3.1.2 fast automatic action test

Using the rated voltage and the electrical load at that voltage.

3.2 Thermal conditions of the test

When the KSD301 thermostat according to the method specified by the manufacturer installed, The product should be exposed to normal room temperature.

3.3 mechanical conditions of the test

3.3.1 Slow test method, The test equipment shall reliably drive the starting element, There is no significant lag between the device and the starting element.

3.3.2 Rapid test methods,

The test equipment shall ensure that the test allows for free operation of the starting element, So as not to interfere with the normal operation of the body.

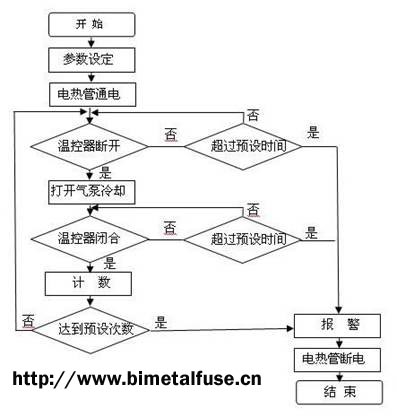

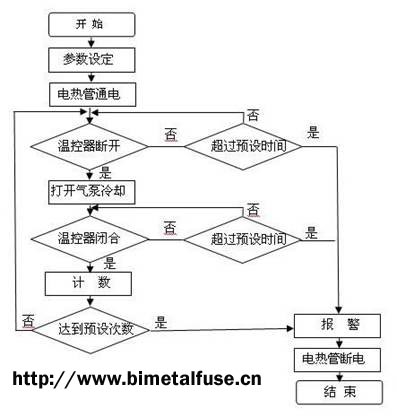

3.3 KSD301 thermostat function flow

To normally closed type KSD301 thermostat, for example. The temperature-sensitive parts of the heating block installed in the surface, Adjust the sample requirements of the electrical load, Set the heating block temperature, Fault alarm time, Life frequency and other parameters. Adjust the cooling gas pressure, So that the frequency and technical requirements to maintain consistency, Start the test, Test flow shown in Figure 1.

Thermostat test flow chart

4, the most close to the actual work of the thermostat test method

During the whole life test, The test piece is fixed on the copper plate, The most close to the actual work of KSD301 thermostat,The impact on the results of the smallest. In the life test,Suitable for all thermostat test standards. Such as: bimetal thermostat,Pressure-type thermostat ,Liquid expansion thermostat.

5, the thermostat life test Summary:

The test method used in the unit for many years,Use in good condition,Can achieve a variety of bimetal thermostat,Capillary, the expansion of the thermostat and other thermostat life test.

Compared with other manufacturers of test results,The detection process more in line with the relevant standard temperature control requirements,Test results are accurate,low cost.

2, temperature control test device introduced

2.1 Equipment parametersTest voltage: 0-300VAC adjustable; Electrical load: 1 ~ 30A adjustable; Number of test setting range: 1000-99999;

Temperature adjustment range: -20 ℃ to 500 ℃;

Cooling air pressure: 0 ~ 1MPa;

Station: 5; own resistance load Taiwan, And an external load Taiwan; Can be preset number of test cycles; With the test sample failure automatic detection and failure alarm function; And shows the number of trials.

3, thermostat testing standards

3.1 Electrical tests

KSD301 thermostat of each circuit, It shall be specified by the manufacturer's rated load test as the basic technical parameters

3.1.1 fast automatic over-voltage, over-current test

1.15 times the rated voltage and the electrical load at that voltage.

3.1.2 fast automatic action test

Using the rated voltage and the electrical load at that voltage.

3.2 Thermal conditions of the test

When the KSD301 thermostat according to the method specified by the manufacturer installed, The product should be exposed to normal room temperature.

3.3 mechanical conditions of the test

3.3.1 Slow test method, The test equipment shall reliably drive the starting element, There is no significant lag between the device and the starting element.

3.3.2 Rapid test methods,

The test equipment shall ensure that the test allows for free operation of the starting element, So as not to interfere with the normal operation of the body.

3.3 KSD301 thermostat function flow

To normally closed type KSD301 thermostat, for example. The temperature-sensitive parts of the heating block installed in the surface, Adjust the sample requirements of the electrical load, Set the heating block temperature, Fault alarm time, Life frequency and other parameters. Adjust the cooling gas pressure, So that the frequency and technical requirements to maintain consistency, Start the test, Test flow shown in Figure 1.

Thermostat test flow chart

4, the most close to the actual work of the thermostat test method

During the whole life test, The test piece is fixed on the copper plate, The most close to the actual work of KSD301 thermostat,The impact on the results of the smallest. In the life test,Suitable for all thermostat test standards. Such as: bimetal thermostat,Pressure-type thermostat ,Liquid expansion thermostat.

5, the thermostat life test Summary:

The test method used in the unit for many years,Use in good condition,Can achieve a variety of bimetal thermostat,Capillary, the expansion of the thermostat and other thermostat life test.

Compared with other manufacturers of test results,The detection process more in line with the relevant standard temperature control requirements,Test results are accurate,low cost.