Ordinary Direct Cooling Single Door Refrigerator Temperature Controller

This kind of temperature controller is often used in the ordinary direct-cooled single-door refrigerator of artificial defrosting, or in the freezing chamber of the double-door refrigerator of Intercooled type controlled by automatic defrosting.

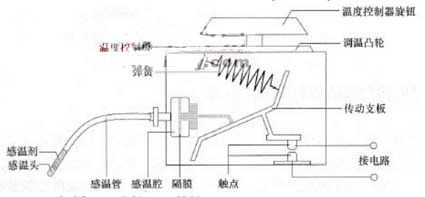

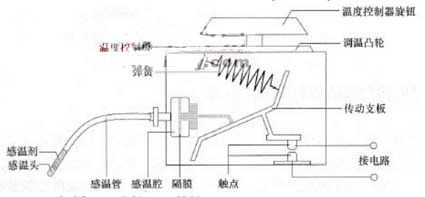

The internal structure of a common temperature controller is shown in Figure 5-9.

The internal structure of a common temperature controller is shown in Figure 5-9.

Normal temperature controller and temperature sensing is mainly composed of a set of micro-switches and other institutions. Pressure sensing chamber temperature sensitive agents are generally chloride or R12. The function of the temperature sensing chamber is to convert the temperature change on the surface of the evaporator or the tank into a pressure change, and push the contact to control the start and stop of the compressor.

Normal temperature controller and temperature sensing is mainly composed of a set of micro-switches and other institutions. Pressure sensing chamber temperature sensitive agents are generally chloride or R12. The function of the temperature sensing chamber is to convert the temperature change on the surface of the evaporator or the tank into a pressure change, and push the contact to control the start and stop of the compressor.

The temperature sensing head (package) is placed at the evaporator and clamped against the evaporator surface or the outlet of the evaporator line. Under normal circumstances, the temperature sensing agent in the temperature sensing bag is in a wet vapor state. When the temperature of the evaporator changes, the pressure of the temperature sensing agent in the temperature sensing package changes, and the pressure is transmitted to the bellows or the air film chamber through the capillary tube, so that it expands and contracts with the pressure change.

This displacement is transmitted and amplified by a mechanical transmission mechanism, which can control the opening or closing of the contacts, and then control the start and stop of the refrigeration compressor. When the evaporator temperature rises, the bellows elongates, pushing the lever of the contact to make it open to the stationary contact, and the compressor operates. When the evaporator temperature is lowered, the pressure of the vapor in the temperature sensing tube drops, the bellows contracts, and the balance spring in the transmission mechanism separates the contacts, cutting off the circuit, thereby stopping the compressor.

The temperature control cam can be rotated by a knob on the temperature controller. If the knob is rotated counter-clockwise, the cam radius becomes larger, the balance spring is elongated, and the pressure added to the diaphragm box increases. In order to make the contacts connected, the temperature sensor in the temperature chamber must increase the pressure (to reach a higher temperature to move the contacts), that is to say, only when the surface temperature of the evaporator rises higher, can the compressor circuit be connected and operated. Therefore, when the temperature adjustment knob rotates counterclockwise, the temperature inside the refrigerator rises. Conversely, when the temperature adjustment knob is rotated clockwise, the temperature inside the refrigerator is lowered.

At normal temperature, the temperature controller's switch is always on (except for the knob to the forced shutdown position). Otherwise, indicating the temperature controller is damaged, the damage is usually the reason the temperature sensing tube leakage or poor contact due to oxidation of contacts.

The temperature sensing head (package) is placed at the evaporator and clamped against the evaporator surface or the outlet of the evaporator line. Under normal circumstances, the temperature sensing agent in the temperature sensing bag is in a wet vapor state. When the temperature of the evaporator changes, the pressure of the temperature sensing agent in the temperature sensing package changes, and the pressure is transmitted to the bellows or the air film chamber through the capillary tube, so that it expands and contracts with the pressure change.

This displacement is transmitted and amplified by a mechanical transmission mechanism, which can control the opening or closing of the contacts, and then control the start and stop of the refrigeration compressor. When the evaporator temperature rises, the bellows elongates, pushing the lever of the contact to make it open to the stationary contact, and the compressor operates. When the evaporator temperature is lowered, the pressure of the vapor in the temperature sensing tube drops, the bellows contracts, and the balance spring in the transmission mechanism separates the contacts, cutting off the circuit, thereby stopping the compressor.

The temperature control cam can be rotated by a knob on the temperature controller. If the knob is rotated counter-clockwise, the cam radius becomes larger, the balance spring is elongated, and the pressure added to the diaphragm box increases. In order to make the contacts connected, the temperature sensor in the temperature chamber must increase the pressure (to reach a higher temperature to move the contacts), that is to say, only when the surface temperature of the evaporator rises higher, can the compressor circuit be connected and operated. Therefore, when the temperature adjustment knob rotates counterclockwise, the temperature inside the refrigerator rises. Conversely, when the temperature adjustment knob is rotated clockwise, the temperature inside the refrigerator is lowered.

At normal temperature, the temperature controller's switch is always on (except for the knob to the forced shutdown position). Otherwise, indicating the temperature controller is damaged, the damage is usually the reason the temperature sensing tube leakage or poor contact due to oxidation of contacts.