NEC, Emerson Organism metal case temperature fuse Common parameters and precautions

NEC, Emerson Organism metal case temperature fuse Common parameters and precautions

product name:

Organism metal case temperature fuse

product description:

At normal operating temperatures, A thermal fuse operates by flowing current from the left lead to the sliding contact,And flows to the right-side lead through the movable contact. When the external temperature reaches the predetermined fusing temperature (Tf). the organic material melts, The compression spring becomes loose, i.e., the spring expands. The movable contact (sliding contact) is separated from the left lead. Loop is opened, The current between the sliding contact and the left lead is cut off. The normal protection of the product safety risks.

Product Features:

Organism metal shell temperature fuse characteristics: a one-time hot-melt, can not be reused.

Commonly used current: 5A, 10A, 15A, 16A, 20A, 25A

Common rated operating temperature (Tf):

At 77 ° C, 77 ° C, 94 ° C, 113 ° C, 133 ° C, 142 ° C, 157 ° C, 172 ° C, 192 ° C, 216 ° C, 227 ° C,

84C, 92C, 95C, 105C, 110C, 115C, 121C, 128C, 130C, 139C, 141C, 144C, 152C, 157C, 169C,

184 ° C, 185 ° C, 192 ° C, 216 ° C, 227 ° C, 228 ° C, 240 ° C, 250 ° C, 280 ° C,

Use the chip:

Organism

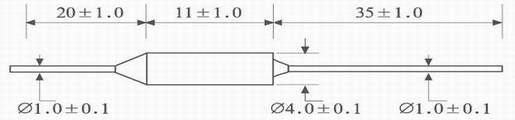

Product Size:

Organometallic Metal Case Temperature Fuse Dimensions: Length 66 (mm) * Diameter 4 (mm)

Dimensional drawings of temperature fuses

Organic metal shell temperature fuse product size are basically the same, Only Emerson G7 series of ordinary product size only 2/3. The customer according to the different current and the temperature choice different product parameter. Yaxun Electronics offers a variety of product design.Welcome to inquire.

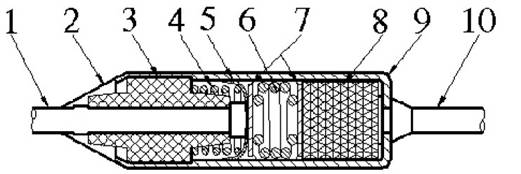

Appearance picture:

Temperature fuse product images

Applications range:

Temperature Fuse Applications:

Communication field: Mobile terminal

Car: Automotive air conditioning heating seat ABS protection

Home Appliance: Soymilk Maker Hair Dryer Iron / Garment Press Juicer Breadmaker Electric Fan More

Large appliances: air conditioning refrigerator electric washing machine

Optoelectronics: Halogen LED lights start capacitor

Components: Capacitance resistance MOV

Electric cars: battery charging

Industrial Control and Automation: Automatic Robots

Composition Materials:

Organism metal shell temperature fuse composition material: 1. A pin, 2. sealing resin, 3. insulating ceramic, 4. small spring, 5. star-shaped reed, 6. coarse spring, 7. wafer, 8. sense Temperature block, 9. Shell, 10. B pin. The following product structure:

Precautions for use:

1. Electrical Characteristics CAUTION:

Each temperature fuse has its rated electrical and temperature parameters. The application shall be such that it operates within the specified rated parameters. These parameters include Tf (rated operating temperature), Th or Tc (holding temperature), Tm (limit temperature) and rated current, voltage.

2. Welding Note:

If the temperature fuse to use solder or tin-way connection with the line, Solder or dip tin is best from the temperature protection body 10mm above. In the case of 300 ℃ solder or dip tin time should be controlled within 1 to 2 seconds is appropriate, If the use of less than 113 ℃ temperature fuse as far as possible not to use solder or dip tin way. Whether it is iron welding, welding or dip tin, Should be completed in a short time,And the side of the welding side to heat, Prevent the occurrence of heat and fuse, an open circuit.

3. Installation Notes:

1> Epoxy resin package side of the lead-out line for bending use,The distance from the epoxy resin parts 8mm away,So as not to damage the insulator,The other end of the lead line of bending,At a distance of 5 mm away from the shell.When bending, bend the lead wire (the epoxy part is not applied).

2> Do not twist the thermal fuse (for example, the pin rotates relative to the housing).

3> The pin should not be damaged during installation, hit the gap, sharp angle bending, burning.

4> sealing resin and shell can not be damaged, burning or overheating.