Motor Overload Setting Calculation

Calculate Size of Contactor, Fuse, CB, Over Load Relay of DOL Starter

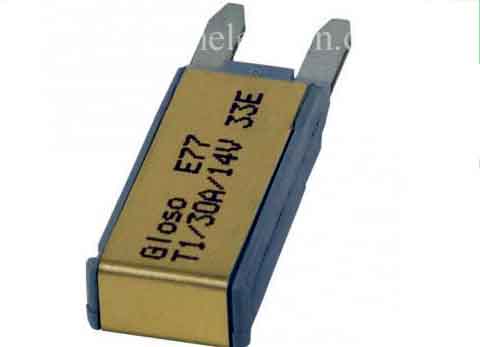

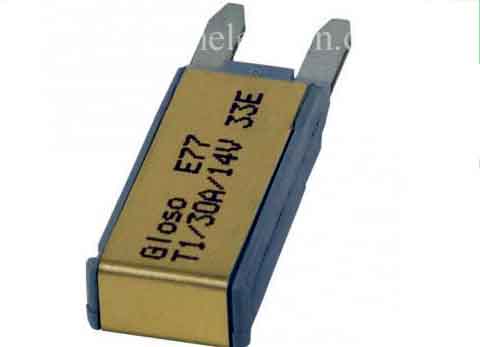

Calculate Size of Contactor, Fuse, C.B, O/L of DOL Starter Calculate Size of each Part of DOL starter for The System Voltage 415V ,5HP Three Phase House hold Application Induction Motor ,Code A, Motor efficiency 80%,Motor RPM 750 ,Power Factor 0.8 , Overload Relay of Starter is Put before Motor.

Motor overload protection Index

Motor overload protection. Low Voltage Products & Systems. 2.1. ABB Inc. • 1SXU000023C0202 Rev. A. Motor overload protection &. Universal motor controller. Thermal overload relays. • Economic overload protection. • Motor applications up to 310 A. • For single and three phase ...

Sizing The DOL Motor Starter Parts (Contactor, Fuse, Circuit Breaker ...

Calculate size of each part of DOL motor starter for the system voltage 415V, 5HP three phase house hold application induction motor, code A, motor efficiency 80%, motor RPM 750, ... Basic Calculation of Motor Torque and Current ... Thermal Overload Relay setting = 100% x Full Load Current (Line).

heat protection - What calculations determine the choice of the ...

The motor trip current does not determine the choice of trip class. Trip class specifies the length of time it will take for the relay to open in an overload condition. Classes 5, 10, 20 & 30 are the most common. Class 5, 10, 20 & 30 overload relays will trip within 5, 10, 20 & 30 seconds respectively at 600% of ...

Motor starting and protection - Schneider Electric

4.2. Electrical braking of 3-phase asynchronous motors. 69. 4.3. Multifunction motor starter units. 74. 4.4. Motors protection. 76. 4.5. Motor losses and heating. 77. 4.6. Causes .... The resistance value is calculated according to the maximum current peak ..... protection against overloads and short circuits with the performance.

Motor_Calculations_-_Part_1_03-3-2003 - Mike Holt Enterprises

They do not provide protection against short-circuits or ground-fault currents (see Figure 7-5). That is the job of the branch and feeder breakers, which do not provide motor overload protection. This arrangement makes motor calculations different from calculations used for other types of loads. Let's look at how to apply ...

Motor Circuit Protection Tables

fault protection for motor branch circuits. Fuses sized in accordance with Column 5 must be used in conjunction with properly sized motor overload protection such as overload relays or solid state motor controllers (430.32). Column 5 fuse sizing provides the maximum NEC® Table 430.52 amp ratings for general purpose.

Understanding Service Factor, Thermal Models, and Overloads

tripped instantly on overload when the thermal damage curve showed considerable ... Induction Motor. The Mathcad® plot of Equation (1) superimposed on the. WEG graph in Fig. 1 proves it to be a perfect match. According to the Thermal Relay Standard IEC-255-8, when a hot ... to provide overload protection. Fig. 3 shows ..

Calculate Size of Contactor, Fuse, C.B, O/L of DOL Starter Calculate Size of each Part of DOL starter for The System Voltage 415V ,5HP Three Phase House hold Application Induction Motor ,Code A, Motor efficiency 80%,Motor RPM 750 ,Power Factor 0.8 , Overload Relay of Starter is Put before Motor.

Motor overload protection Index

Motor overload protection. Low Voltage Products & Systems. 2.1. ABB Inc. • 1SXU000023C0202 Rev. A. Motor overload protection &. Universal motor controller. Thermal overload relays. • Economic overload protection. • Motor applications up to 310 A. • For single and three phase ...

Sizing The DOL Motor Starter Parts (Contactor, Fuse, Circuit Breaker ...

Calculate size of each part of DOL motor starter for the system voltage 415V, 5HP three phase house hold application induction motor, code A, motor efficiency 80%, motor RPM 750, ... Basic Calculation of Motor Torque and Current ... Thermal Overload Relay setting = 100% x Full Load Current (Line).

heat protection - What calculations determine the choice of the ...

The motor trip current does not determine the choice of trip class. Trip class specifies the length of time it will take for the relay to open in an overload condition. Classes 5, 10, 20 & 30 are the most common. Class 5, 10, 20 & 30 overload relays will trip within 5, 10, 20 & 30 seconds respectively at 600% of ...

Motor starting and protection - Schneider Electric

4.2. Electrical braking of 3-phase asynchronous motors. 69. 4.3. Multifunction motor starter units. 74. 4.4. Motors protection. 76. 4.5. Motor losses and heating. 77. 4.6. Causes .... The resistance value is calculated according to the maximum current peak ..... protection against overloads and short circuits with the performance.

Motor_Calculations_-_Part_1_03-3-2003 - Mike Holt Enterprises

They do not provide protection against short-circuits or ground-fault currents (see Figure 7-5). That is the job of the branch and feeder breakers, which do not provide motor overload protection. This arrangement makes motor calculations different from calculations used for other types of loads. Let's look at how to apply ...

Motor Circuit Protection Tables

fault protection for motor branch circuits. Fuses sized in accordance with Column 5 must be used in conjunction with properly sized motor overload protection such as overload relays or solid state motor controllers (430.32). Column 5 fuse sizing provides the maximum NEC® Table 430.52 amp ratings for general purpose.

Understanding Service Factor, Thermal Models, and Overloads

tripped instantly on overload when the thermal damage curve showed considerable ... Induction Motor. The Mathcad® plot of Equation (1) superimposed on the. WEG graph in Fig. 1 proves it to be a perfect match. According to the Thermal Relay Standard IEC-255-8, when a hot ... to provide overload protection. Fig. 3 shows ..