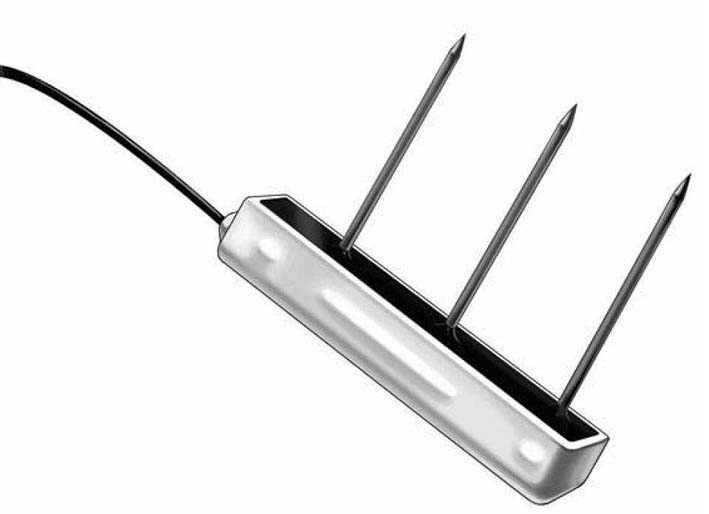

High Temperature Sensor

Involved in many industries such as oil pipelines, water conservancy and hydropower, railway transportation, intelligent buildings, production automation, aerospace, military, petrochemical, oil wells, power, ships, machine tools, pipeline air supply, boiler negative pressure, high-temperature test machine pressure testing, etc.

Working principle of high temperature sensor:

The pressure of the wind pressure sensor directly acts on the diaphragm of the sensor, causing the diaphragm to generate a slight displacement proportional to the pressure of the medium, causing the resistance of the sensor to change, and detecting this change with an electronic circuit. And convert and output a standard signal corresponding to this pressure.

The main parameters

Range: -0.1 ~ 0 ~ 1 ~ 150 (MPa)

Comprehensive accuracy: 0.25% FS, 0.5% FS, 1.0% FS

Output signal: 4 ~ 20mA (two-wire system), 0 ~ 5V, 1 ~ 5V, 0 ~ 10V (three-wire system)

Power supply voltage: 24DCV (9 ~ 36DCV)

Range temperature drift: ≤ ± 0.05% FS ℃

Compensation temperature: 0 ~ 70 ℃

Safe overload: 150% FS

Limit overload: 200% FS

Response time: 5 mS (rising to 90% FS)

Load resistance: Current output type: maximum 800Ω; voltage output type: greater than 5KΩ

Insulation resistance: greater than 2000MΩ (100VDC)

Sealing grade: IP65

Long-term stability: 0.1% FS / year

Vibration effect: In the mechanical vibration frequency 20Hz ~ 1000Hz, the output change is less than 0.1% FS

Electrical interface (signal interface): Hessman connector + four-core shielded wire

Mechanical connection (thread interface): 1 / 2-20UNF, M14 × 1.5, M20 × 1.5, M22 × 1.5, etc. Other threads can be designed according to customer requirements

Main features

1. Sensor: a device or device that can feel the specified measured and converted into a usable output signal according to a certain rule. Usually consists of sensitive components and conversion components.

① Sensitive element refers to the part of the sensor that can be measured directly (or in response).

②Conversion element refers to the part of the sensor that can sense (or respond to) the north side of the sensor and convert it into electrical signals that are transmitted and / or measured.

③When the output is a specified standard signal, it is called a transmitter.

2. Measuring range: the range of the measured value within the allowable error limit.

3. Range: the algebraic difference between the upper and lower limits of the measurement range.

4. Accuracy: the degree of consistency between the measured result and the true value.

5. Recovery from: In all of the following conditions, the measured amount of the same degree of compliance between the results obtained several successive measurements.

6. Resolving power: the smallest change that can be detected by the sensor within the specified measuring range circle.

7. Threshold: The smallest change that can be measured at the output of the sensor.

8. Zero position: The state that minimizes the absolute value of the output, such as the equilibrium state.

9. Excitation: External energy (voltage or current) applied to make the sensor work properly.

10. Maximum excitation: the maximum value of the excitation voltage or current that can be applied to the sensor under city conditions.

11. Input impedance: the impedance measured at the input end of the sensor when the output end is short-circuited.

12. Output: The amount of electricity generated by the sensor and applied as a function of the measured value.

13. Output impedance: the impedance measured at the output of the sensor when the input is short-circuited.

14. Zero output: Under the conditions in the city, the output of the sensor when the added is measured as zero.

15. Hysteresis: within the specified range, when the measured value increases and decreases, the maximum difference in the output.

16. Late: The time delay of the output signal change relative to the input signal change.

17. Drift: In a certain time interval, the sensor output is finally measured and the undesired change is irrelevant.

18. Zero drift: the change in zero output at specified time intervals and indoor conditions.

19. Sensitivity: the ratio of the increment of the sensor output to the corresponding increment of the input.

20. Sensitivity drift: Changes in the slope of the calibration curve due to changes in sensitivity.

21. Thermal sensitivity drift: Sensitivity drift caused by changes in sensitivity.

22. Thermal zero drift: zero drift due to changes in ambient temperature.

23. Linearity: The degree to which the calibration curve is consistent with a specified limit.

24. Philippine linearity: the degree to which the calibration curve deviates from a specified straight line.

25. Long-term stability: the sensor can still maintain the ability to not exceed the allowable error within the specified time.

26. Inherent reliability: In the absence of resistance, the sensor's free (without external force) oscillation reliability.

27. Response: The characteristic of the measured change at the time of output.

28. Compensated temperature range: the temperature range compensated by keeping the sensor within the range and zero balance within the specified limits.

29. Creep: When the measured machine has many environmental conditions that remain constant, the output changes within a specified time.

30. Insulation resistance: If there is no other regulation, it means the resistance value measured between the specified insulation parts of the sensor when a specified DC voltage is applied at room temperature.